By Brandon Johnson, DataPlus Communications

Since its first classes were held on campus in 1957, University of Nevada, Las Vegas (UNLV) has transformed itself from a small branch college into a thriving 332-acre urban research institution, currently one of only 99 universities classified as RU/H, high research activity, by the Carnegie Classification of Institutions of Higher Education.

UNLV’s success as a research institution is mirrored by the commitment and mission of its IT department-“The Office of Information Technology provides leadership in helping faculty, students and staff utilize innovative technologies … including development and support of applications that meet their changing needs.”

True to its promise, an innovative decision was made in 2006 to adopt a new, yet still unfamiliar, blown fiber network infrastructure technology versus the still widely used, decades-old installation method of pulling optical fiber cable. That decision was critical to meet the onslaught of continuous bandwidth-hungry research applications and ever-increasing network Gbits/sec speeds within a constrained budget. Did UNLV’s IT decision makers make the correct choice?

Its blown fiber infrastructure technology has served the university well. However, recent innovations in microduct and air-jet technology by the Dura-Line and AFL companies respectively would allow UNLV to increase network capacity even further and introduce greater optical fiber counts than the older system would support. In November 2014 UNLV installed the new MicroDuct and fiber to quickly upgrade the bandwidth requirements in key buildings.

UNLV is assured that its network has the maximum capacity possible for the growth, expansion, mega bandwidth increases, and the latest technology applications required by a research institution. Unlike conventional optical fiber network infrastructures, air-jet technology provides unprecedented benefits for today’s high-density, high-speed enterprise networks including the following.

- Virtually unlimited fiber pathway and bandwidth capacity, eliminating congested conduit and duct problems

- Immediately scalable, real-time already futureproofed sustainable network; eliminating dark fiber

- Fast and easy fiber installations, upgrades, and network moves/adds/changes in hours versus the days or weeks associated with a conventional infrastructure, even in hard-to-reach campus areas

- Flexibility in infrastructure design, reducing or eliminating the need for innerduct and additional conduit

- No physical disruption to campus grounds or inside building fiber installations, promoting safety

- Continuous fiber runs, eliminating splicing and potential points of network failure

- Faster network restoration, reducing or eliminating network downtime

- More than 90 percent labor cost savings for continuous return on investment

These attributes address UNLV’s mission and can serve as a model for all colleges and universities, regardless of size, given bring-your-own-device (BYOD), high-definition video, growth of online courses, and the ongoing influx of emerging high-density-driven technology challenges necessary to best meet the needs of students, faculty and staff.

Air-jetted fiber infrastructure

At the heart of an air-jetted fiber infrastructure is the MicroDuct. The bundled Dura-Line FuturePath MicroDuct pictured herein makes up the campus fiber pathway topology in and between buildings. These ducts include high-density polyethylene (HDPE) OSP, riser, plenum, and low-smoke zero halogen options as dictated by location in the network. For inter- and intranetwork connectivity, these MicroDucts are independently riser and plenum rated, for example.

The interconnection of UNLV’s buildings from one to another simply requires that outdoor MicroDuct be connected with push-fit couplings to an indoor plenum or riser MicroDuct in seconds. Because the Jetted MicroCable is installed after the connections are made, splicing and related labor costs for skilled workers have been eliminated. By eliminating splicing, which creates potential points of network failure and is necessary with conventional cable pulls, an air-jetted infrastructure’s point-to-point connectivity improves signal integrity for better transmission and reliability.

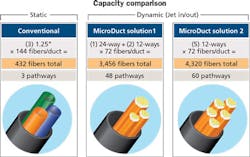

These bundled MicroDucts, enclosed in a protective jacket, replace traditional innerduct, can be direct-buried thereby eliminating the need for conduit, or can be placed within existing conduit, as was the case with UNLV’s installation. The bundled MicroDuct fiber pathway provides virtually unlimited bandwidth and fiber capacity. The new Dura-Line MicroDuct innovation, when considering 5 bundles of MicroDucts (each made up of 12 individual inner MicroDucts) for a total of 60 reusable pathways, provides a 1900-percent increase in capacity over conventional cabling. The increased capacity (detailed in the figure on page 24) solves congested conduit and duct-bank problems, while reducing or eliminating the need for additional conduit and related installation costs. Unused pathways remain empty for future expansion.

It is through the bundled MicroDuct pathway that any optical fiber type Jetted MicroCable can be jetted in and out of the network anywhere and at any time at typical speeds of 200 feet per minute. Because UNLV can jet in and out the exact type of fiber and counts quickly and easily for its changing requirements, the university always has sufficient capacity and is no longer pigeonholed to the guesswork of which type and count of fiber it will need in the future. This reality enables the university to do the following.

- Eliminate the potential waste and cost of installing dark fiber that could become obsolete

- Install only the fiber types and counts the university needs, paying as it goes and grows

- Ensure the university network is ready to install the latest fiber-type innovations, staying ahead of the technology curve

- Allow university IT with real-time control over the network to quickly respond to the needs and requirements of more than 28,000 students and a growing number of faculty and staff

The bundled MicroDuct pathway supports multiple fiber-optic cabling topologies, including centralized/home-run, star, hierarchical star, and passive optical LAN and also offers maximum flexibility for infrastructure design based upon the use and locations of MicroDuct distribution boxes.

Flexibility and cost savings

The MicroDuct distribution boxes (MDBs) are used at MicroDuct fiber pathway branching locations. Rerouting, network MACs, and maintenance of the pathway are accomplished at the MDBs. Demarcation of each pathway within the MicroDuct facilitates fast and easy network segregation, including various security classifications of data, and eliminates cable hunting for ease of troubleshooting. These units are typically located in telecom rooms and in strategically located outdoor vaults.

The MicroDuct pathway and MDBs provide UNLV with maximum versatility in its network infrastructure design, eliminating entrance into manholes, handholes, and access points. When UNLV adds new facilities, the bundled MicroDuct needs to be extended only from the local or closest MDB to the new building. This allows for the fiber to be air-jetted in minutes to the fiber termination unit also located in the telecom room, thereby eliminating disruption and saving the considerable labor and pathway infrastructure costs associated with conventional cabling. Had a conventional cabling infrastructure been in place for this scenario, a large installation crew would have had to undergo the time-consuming process of installing conduit and innerduct from the building back to wherever the central data center is located and then pull in the optical fiber.

For UNLV’s 2014 capacity upgrade, the new 7-way and 24-way bundled FuturePath MicroDucts were installed in this fashion, from the closest MDBs in pre-existing vaults to the nearest buildings requiring the upcoming fiber installation upgrades. Jonathan Myers, UNLV’s information technology network engineer, explains, “We installed MDBs in some areas where we could have pulled straight through the vault. That way, it is easy to branch out at any time in the future, without additional disruptive access to the campus.”

Non-disruptive installation

With the bundled FuturePath MicroDuct fiber pathway in MDBs in place, UNLV is ready for the optical fiber installation upgrades in the buildings requiring additional bandwidth. Using the industry’s latest 72-fiber Jetted MicroCable innovations that fits into the 8.5-mm x 6-mm 24-way MicroDuct, UNLV will meet the highest density applications for its research buildings. Installers quickly jetted out the previous 24-strand fiber from the older system and jetted in the greater-fiber-count Jetted MicroCable.

The optical fiber used in Jetted MicroCables is the same 250-micron glass as used in conventional fiber cables. All optical fiber types are available including standard singlemode (OS2), bend-insensitive singlemode, 62.5-micron Om1 multimode, and 50-micron bend-insensitive Om2, Om3, Om4 and Om4+ multimode. These optical fibers are protected in a robust fiber cable with aramid strength members, water-blocking material, and a specially designed lightweight ribbed outer jacket that provides very low surface friction with the MicroDuct, yet provides the necessary air drag to allow for very long jetting distances of 3,000 feet-plus when using compressed air and a jetting head.

With two installers located at strategic locations on campus, 3,000 feet of 72-count singlemode fiber was jetted in a continuous splice-free fiber run providing the needed bandwidth for several science and technology buildings. The fiber was then terminated using the same methods as used with conventional cabling.

The fiber upgrade took the two installers only 30 minutes to complete without ever getting their hands dirty. Had the installation been done conventionally, it would have taken a crew of six to eight installers a full eight-hour day to have pulled 3,000 feet of cable. The Jetted MicroCable installation was 94-percent faster than conventional, saving the equivalent percentage in labor costs. Once the bundled MicroDuct infrastructure is in place, these savings are repeated with each fiber-installation project, yielding continuous ROI. According to Chris Tettamanti, RCDD, general manager of one of UNLV’s contracting companies DataPlus, “Savings of up to 95 percent in jetting future fiber additions compared to conventional fiber are not unusual.”

Because the MicroDuct pathway distribution and fiber installation are completed behind the scenes in telecom rooms, blown-fiber technology is environmentally clean, non-obtrusive to the daily activities of students and staff, and physically non-disruptive to the university’s grounds and buildings.

“Part of being an RU/H, high-research activity, institution is that network bandwidth is in increasingly high demand with researchers moving large files over the network. The ability to take any infrastructure that’s currently in the ground and leverage it with high-density fiber, without having to further dig up the campus, is a very important factor,” states Myers.

A look ahead

UNLV plans additional installations of optical fiber to meet the bandwidth needs and goals of the university, including a new hotel administration building, a new two-story clubhouse next to the baseball field, and a major addition to the Thomas and Mack arena.

With the ability to jet in and out optical fiber anywhere and at any time throughout the UNLV network, there is no end to the university’s fiber and bandwidth lifecycle. Equipped with a real-time, continuously futureproofed network, UNLV can quickly and easily implement the latest bandwidth-rich, high-speed technologies necessary to meet the continuous high-tech needs of a prominent research institution. The university’s IT department, true to its mission, is ready at a moment’s notice to respond rapidly, efficiently, and cost effectively to the emerging technology needs, growth, and changing requirements of students, faculty, staff, and the Las Vegas community that it serves.

Brandon Johnson is the owner of DataPlus Communications (www.dpcnv.com), a UNLV contractor company. He can be reached at (702) 795-3282 or [email protected].