Gail Leach Carvelli

On the surface, pulling cable appears to be a simple task--attach the pulling grip, place the cable in the conduit, and begin pulling. But it`s what you can`t see in the conduit that can turn the process into a nightmare. Debris, sharp edges, and an uneven surface can snag or jam and ultimately damage the cable. Even with a good, clean conduit, the friction of the cable jacket on the conduit wall can sometimes damage the cable.

Cable-pulling lubricants can minimize friction. Made out of materials such as polymer, wax, or silicone, lubricants coat the cable being pulled with a film that helps it glide over obstacles during the pull. "Lubricants reduce the amount of pulling tension needed to install wire and cable," notes Ron Petersen, senior product development chemist for ideal Industries. "Technicians can pull longer distances of wire without making splices and without exceeding the maximum tension allowed by the cable manufacturer." (See Product Update table, page 25)

Know your cable type

For a cable lubricant to do its job, it needs to be compatible with the type of cable being pulled. Some lubricants are designed to work with fiber-optic cable, while others work better with copper or coaxial cable. Other lubricants should only be used for electrical cables. Cable-jacket material is also a consideration. For example, although most manufacturers produce lubricants that will work with any jacket, they also admit that a polymer-based lube works best when you are pulling a fiber-optic cable with a polyethylene jacket.

Failure to determine the lubricant`s compatibility can lead to costly problems years after the installation has been completed, says Don Larson, national sales manager for American Polywater Corp. "Most problems don`t occur until seven to ten years after the cable has been pulled and energized," he explains. "An installer will say the cable worked after he pulled it. But over time, an improper lubricant may cause stress cracking or other deterioration of the cable jacket. This is why automotive greases and dishwashing liquids are never appropriate as pulling lubricants. There is too much chance of jacket damage."

The easiest way to determine compatibility is to ask the cable manufacturer what it recommends for its particular cable. Many cable manufacturers have tested different lubricants with their cables. "The only way to know for sure," says Larson, "is if the cable manufacturer has a written list of lubricants that are compatible with its cable jacket."

However, Gary Goetzinger of River City Communications Corp. (Sacramento, CA), says he relies on lubricant manufacturers to produce lubes that are universally compatible. "I just assume that the manufacturers have done comprehensive testing for standard, cable-jacket compatibility," he says. "And I assume that the newer lubricants in the market are compatible with everything because they are primarily water-based."

Different lubes for different jobs

Some of the first cable lubricants were made of soap or clay. But those materials tended to dry and would often cement the cable to the bottom of the conduit, making cable removal almost impossible. While these materials are still used today--mainly because of their inexpensive price tag--manufacturers have created lubricants with a more slippery residue for specific pulling applications. While water makes up a large portion--usually about 90%--of the lubricant, other materials create the slippery action.

Anna Marie Rosen, senior technical service engineer for 3M`s Electrical Products Div., says the reason for the low percentage of solid material is to reduce the potential of blocking the cable. "The liquid will evaporate and the low-solid content will minimize the residue left behind," she says. "This avoids the problems that could occur when more cables are pulled through the conduit."

Wax is probably one of the best-known lubricants, but it should only be used for pulling electrical wires. However, notes Larson, "Wax-based lubricants are certainly the most common, but should not be used on communications cable," adds Larson. "Communications cable jackets are made of a different material than that of electrical wires. Be especially careful with the polyethylene-type jackets."

But ideal`s Petersen maintains that some wax-based lubricants have been re-engineered to work with communications cables. "Waxes provide better `clingability.` They stay on the wire better for longer pulls, without rubbing off," he says. "You don`t want the lubricant rubbing off the cable before the pull is complete."

With the advent of communications cables, polymer and silicone-based lubricants have emerged as strong players in the industry. These materials come in several forms, such as thick gel and paste for applying by hand, and are also available in thinner gel and liquid formulas that can be poured directly into the conduit. "As a general rule," says American Polywater`s Larson, "use thick gels in premises wiring or inside-building-type work. Use stringy gels when pulling copper cable or when pulling fiber into a large conduit, and use gravity-feed liquid-type lubricants when pulling fiber-optic cables into innerduct or small conduit."

Installers need to ensure that the lubricant is coating the cable well. This is especially important with fiber-optic cable, which generally weighs less than copper cable. The lubricant must completely coat the cable and stay on during the entire pull. Fiber-optic cable will rub on the bottom of the conduit as it is pulled, but it will also rub along the top and sides because of its weight.

Perhaps the most slippery lubricants on the market are those made of silicone, which makes them more expensive. Some silicone lubricants are also manufactured with little ball bearings or microspheres suspended in the lube. The ball bearings help the cable glide during the pull. "This type of lubricant almost works too well," says River City`s Goetzinger. "It is so slick that it is often difficult to hold onto the cable, especially plenum-jacketed cable."

Installers need to make sure that silicone does not affect the environment they are pulling in. According to Larson, some industries--for example, automotive, photography, and paint--do not allow silicones within their facilities. "The release properties of silicone can wreck the photo-developing process," he says. "And they can cause havoc with different paints and paint adhesion."

Using lubricants in cold weather presents another set of challenges, so most manufacturers offer a winter-grade lubricant that will not freeze or separate during extreme conditions. Most are made with a nonhazardous antifreeze. "You would not want to add your ordinary car antifreeze to the cable lubricant," says Petersen. "Most winter-grade lubricants use a nonpoisonous antifreeze."

Cable lubricants can be an important part of an installation, but despite their importance, their cost is moderate. A gallon of polymer-based lubricant can cost $8 to $12, while a silicone-based lubricant can cost $15 a gallon. Waxes, on the other hand, average about $12 a gallon.

Goetzinger says that finding a nontoxic product is also important. "Invariably," he explains, "you are going to be covered with it from time to time, and you don`t want anything that is going to burn your skin."

For a list of manufacturers and their products, see Product Update table, page 25. q

A Look at Coefficient of Friction

Nearly every cable-lubricant manufacturer lists a coefficient-of-friction value. The lower the value, the more slippery the lubricant is. The tricky part, according to Ron Petersen, senior product development chemist for ideal Industries Inc., is that each manufacturer is able to determine these values using its own system.

OTesting varies from manufacturer to manufacturer. Almost all have their own way of determining this value,O says Petersen.

Anna Marie Rosen, senior technical service engineer for 3M?s Electrical Products Div., agrees. OBecause there is no standard, everyone can measure and get a different answer,O she says. OWe?ve actually gotten away from listing that value on our products.O

What makes this situation even more difficult is that the coefficient of friction will change whenever you use a different type of cable in a different type of conduit or innerduct. OThe number is highly dependent on the two surfaces, i.e., the cable jacket and conduit materials,O says Don Larson, national sales manager for American Polywater Corp. ODuring the pull, the coefficient of friction and the cable tension are affected by many factors, including sidewall tension, cable stiffness, percent of conduit fill, and temperature.O

While lubricants can lower the coefficient of friction, their effect depends on the lubricant?s quality, how it is applied, and how well it clings to the cable over long installations. To get around these fluctuating variables, many manufacturers will list an average coefficient of friction, which is determined after a variety of tests in many conditions.

OAn accurate and supportable friction coefficient can be used in the pull equations to plan and optimize a pull,O says Larson. OThat?s why we?ve done so much work to characterize them.O

An installer manually applies a stringy, pourable gel from American Polywater Corp. on copper cables.

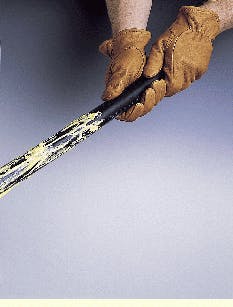

Wax-based cable lubricants, such as Yellow 77 from ideal Industries Inc., are some of the most commonly used lubricants for pulling cable.