by David Hessong and Jennifer Cline

Facilities of all sizes can reap system-performance benefits from an off-the-shelf solution.

The data center market in North America continues to grow and evolve. Small to medium-sized data centers continue to increase in numbers; data centers of all sizes are demanding products that provide the benefits and flexibility of a pre-terminated, modular cabling infrastructure without some of the drawbacks typically associated with these solutions.

The many requirements for performance and flexibility in the data center have increased the need for alternative cabling options. One alternative is the integrated trunk module (ITM), which provides a value-added component to the data center toolbox for tackling challenging cabling requirements. This product contains a 12-fiber trunk assembly integrated into a breakout module.

With products such as the ITM in the data center, precise calculating and planning of channel-link lengths are not required, because the desired amount of cable is deployed from the ITM to create a no-slack channel. Additionally, integration of a trunk and module eliminates a multi-fiber push-on (MPO) connector pair, yielding a decrease in channel insertion loss. Products such as the ITM are adding flexibility to data center designs by providing an off-the-shelf, modular system solution for fast fiber-optic deployment.

The ITM can provide a convenient method for deploying and/or redeploying optical connectivity, and is suitable for use in small data centers (main cross-connect to the system equipment cabinet) or large data centers (zone distribution area to the system equipment cabinet). The sliding tray, which rotates to one side, is designed to make it easy to access and deploy the trunk cable that is pre-terminated with a pinned or non-pinned MPO connector. Once the trunk cable has been deployed, the remaining excess cable can be stored within the sliding tray to eliminate slack.

When speaking with data center managers about deployment of a pre-terminated, modular solution, two issues frequently arise: lead times for these custom-assembled trunks, and cable slack management.

Dealing with tough questions

Cable manufacturers and distributors have tried to address lead-time issues by stocking factory-terminated assemblies in predetermined fiber counts and lengths. While this strategy helps address the lead-time issue, it often exacerbates the issue of slack management. For example, in a time-sensitive situation, data center managers may be left with no choice other than to order a stocked 100-foot pre-terminated assembly, even though the required length is only 80 feet. As a result, the manager has to find a way to deal with 20 feet of cable slack.

For data center managers who are unable or unwilling to handle trunk lead times or additional cable slack, one solution is to keep modules and unterminated ribbon cable in stock, and field-connectorize the cable with MPO connectors. Field termination of MPO connectors has become a more viable option in recent years with the introduction of no-epoxy/no-polish MPO connectors and universal wiring. This option can be attractive in data centers, where large quantities of trunks may be required with little to no forecasted visibility, making the lead times of some pre-terminated solutions prohibitive.

Data center designers and managers also face the issue of channel insertion loss. As network speeds continue to increase, the allowable channel insertion loss continues to decrease. Ten-Gigabit Ethernet systems over laser-optimized 50-µm OM3 multimode fiber require very tight channel insertion loss budgets to achieve maximum system distance capabilities.

As mentioned, integration of a trunk and module eliminates an MPO connector pair, yielding a decrease in channel insertion loss. This feature offers system designers more options when designing their networks because they can still enjoy the benefits and flexibility of pre-terminated, modular solutions, as well as reduced channel loss. The ITM helps to address all these issues-lead times, slack management, and channel insertion loss-in large and small data centers.

At work in the data center

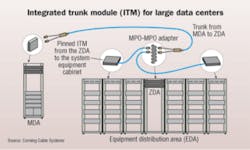

A typical topology in a large data center involves installing a high-fiber-count trunk from the main distribution area (MDA) to a zone distribution area (ZDA). From the ZDA, extender trunks, harnesses or multiple patch cords are then used to provide connectivity to the end equipment, such as servers or storage devices, in the equipment distribution areas (EDAs). An alternative to using these products from the ZDA to the EDAs is the integrated trunk module with a pinned MPO connector.

The ITM can be installed in individual cabinets or rack, then the integrated trunk is pulled to the ZDA where the pinned MPO connector is mated to the trunk from the MDA. Once the trunk cable has been deployed, the remaining excess cable can be stored within the ITM’s sliding tray.

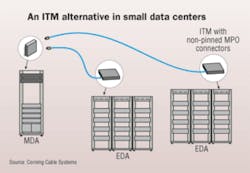

A typical topology in a small data center involves installing a low-fiber-count trunk from the MDA to the end equipment, such as servers or storage devices, in the EDAs. An alternative to using trunk assemblies with a plug-and-play module on each end is the ITM with a non-pinned MPO connector mated to a plug-and-play module.

Here, the ITM can be installed in the individual cabinets or racks, then the integrated trunk pulled to the MDA where the non-pinned MPO connector is installed in the plug-and-play module. Again, once the trunk cable has been deployed, the remaining excess cable can be stored within the ITM’s sliding tray to eliminate slack.

Using the ITM in these scenarios offers several advantages, including:

- Installation of a slack-free channel;

- Elimination of lead times associated with made-to-order assemblies;

- Reduction in the quantity of parts required for a cabling infrastructure;

- Reduction of channel insertion loss by eliminating one MPO connection.

For an ITM installation with a ZDA, the channel loss is 2.6 dB, plus fiber loss. For a traditional installation, where an extender trunk and module are used instead of the ITM, the channel insertion loss increases to 3.35 dB, plus fiber loss.

For an installation in which the ITM mates directly with a plug-and-play module, the channel loss is 1.8 dB, plus fiber loss. For a traditional installation, where a trunk and two modules are used instead of the ITM and a single module, the channel insertion loss increases to 2.6 dB, plus fiber loss.

Compared to a traditional pre-terminated, modular installation, the only product required when using the ITM solution is the ITM itself. The separate module and trunk typically required in the EDA are no longer necessary.

The ITM is available in 40- and 80-foot lengths, and all slack is stored within the unit. It can be purchased directly from distributor inventory, in contrast to the lead times associated with traditional trunk assemblies that are custom-manufactured to specified lengths. End users can maintain stock of ITMs for quick deployment when required.DAVID HESSONG and JENNIFER CLINE are engineers with Corning Cable Systems (www.corningcablesystems.com).