Reducing ergonomic risks for installers of fiber-optic and copper structured cabling networks

By Mansi Ghandi, TechTable -- As the world adapts to recent technological advancements in readily deployable virtualization, cloud computing, colocation and enterprise networks, the migration towards 40 Gbps copper and 100 Gbps fiber cabling infrastructure will see the daily work practices of telecommunications installers undergo a drastic change. Installers of highly complex cabling projects have seen rapid advances and developments in termination technologies over the last few years, but no improvement to their typically cluttered and uncomfortable working environment or to the repetitive manual handling of cables, jacks, patch panels and punch-down tools.

Typical work practices

Manual patch panel termination tends to be a highly repetitive task, with installers often on site for weeks or months and generally left to devise their own platform and workspace. This situation can be made all the more difficult due to space constraints in communications rooms and the shifting landscape that is typical of a building site.

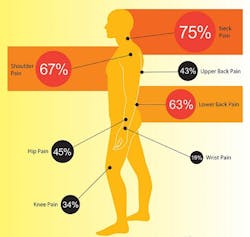

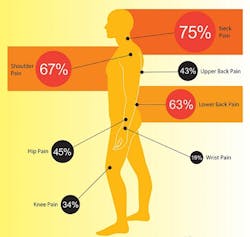

What are the OHS risks? The repetitive nature of the tasks, coupled with some fairly primitive working conditions, mean that neck, shoulder and back pain is not uncommon among telecommunications technicians. A survey of technicians conducted by Health and Safety Consultant Glenda Snoxall of Safety Key Solutions in 2011, endeavored to identify the key areas of body discomfort. The survey results showed that during the processing of data cable termination, a staggering 75% of respondents suffered from neck pain, 67% from shoulder pain and 63% from lower back pain.

The Australian National Code of Practice for the Prevention of Musculoskeletal Disorders (2007) sets out practical guidance on how to reduce the risks of musculoskeletal disorder (MSD) from manual tasks undertaken at work. The code was designed for use by employers, owners of premises, OHS professionals, and designers, manufacturers and suppliers of items used in any workplace. The code calls for control over risk of MSD through elimination or reduction in the number of repetitive actions, awkward postures, sustained postures and movements required over time to perform a manual task, as well as to reduce the amount of time that a user needs to spend carrying out manual tasks associated with an item being designed, supplied or manufactured.

According to the code, as the pace of work increases, postures or movements become more repetitive, which means the same muscles are being used continuously. The speed of movement can also increase the risk of injury. Posture affects the muscular effort needed to perform a task and how quickly muscles fatigue. Posture and movement are particularly important when forceful and/or repetitive tasks are performed or postures are held for prolonged periods. Repetitive awkward postures are those positions where the whole body, or parts thereof, is not in a normal or neutral position. As a joint moves further away from its normal position, more muscular effort is needed to achieve the same force and where these postures are assumed repetitively, the risk of MSD increases.

Sustained awkward postures are those awkward positions where the whole body or parts of the body (that are not in their normal position) are held for more than 30 seconds at a time. Repeated or sustained movement occurs when the task involves performing the same actions over and over. In essence, the milk-crate scenario described earlier encompasses all of these risk factors combined; prolonged repetitive movement in both sustained and awkward postures leaves many communications technicians open to the threat of ongoing MSD pain.

Addressing the issue

David McHarg, a former communications technician and managing director of TechTable Pty Ltd, saw an obvious gap in the market and an opportunity to improve working conditions for this industry group. He worked with OHS consultant Glenda Snoxall, ACT Safety Regulator and Ergonomist Richard Siddell and Peter McKay of Industrious Design to develop a solution. The team worked together initially to develop an in-depth risk assessment and report in accordance with the code of practice.

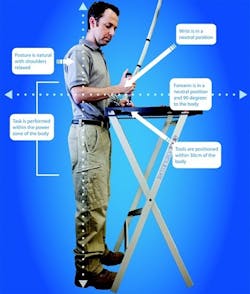

They then went on to design a product that provided a better working platform, addressing the key features required from a health and safety aspect and ensured compliance with the manual handling code of practice, which covers: working height, tool arrangement and distance, weight, carrying method. The TechTable was born: a slimline, portable, lightweight and sturdy work surface for communications technicians. Market input was sought, particularly on size, weight, tool tray size and padding requirement.

The TechTable allows technicians to perform tasks at waist height and to easily rotate between standing and seated positions. It provides a stable and comfortable platform and is height adjustable, allowing technicians to terminate at their ideal height.

Improving installer efficiency and performance

While the TechTable has eliminated or reduced many of the identified manual handling risks associated with cable installation, testing has also proven it to increase an installer’s productivity by up to 24%. Moreover, it is designed for easy daily transport inside a padded carry bag and the set-up time is less than one minute. The dimensions are designed to suit tight-fit positions in cluttered computer rack environments, telecommunications rooms and data centers.

The product was officially launched in the US at the recent 2014 BICSI Fall Conference in Anaheim, CA. For more information on the TechTable and to find out where it can be purchased, visit techtable.co.