5 reasons not to install 62.5-micron fiber in an enterprise network

From the August, 2013 Issue of Cabling Installation & Maintenance Magazine

Pointing out the flaws in the five most-common reasons enterprises choose 62.5-micron OM1 fiber.

by John Kamino, OFS

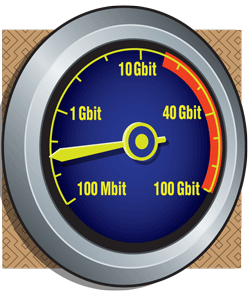

We in the optical-fiber industry often ask ourselves, "Why are companies still installing 62.5-micron (OM1) fiber in their high-speed enterprise networks?" In our minds, there is no obvious answer to this question. Of course, we're happy to sell you any type of fiber you like. But at the same time, we know that the advanced 50-micron fibers known as OM3 and OM4 fiber have much greater information-carrying capacity and support the latest 40- and 100-Gbit/sec networks. OM1 fiber, on the other hand, is not even included in the latest data center network cabling standard, ANSI/TIA-942-A, and is not expected to be included in future revisions of ISO/IEC cabling standards.

And yet, 62.5-micron OM1 fiber comprises more than 25 percent of the multimode fiber sold in North America (Matthew Burroughs, 1Q2013 Multimode Quarterly Detail Report), and more than 30 percent of the multimode fiber sold worldwide (CRU Telecom Cables Market Outlook, February 2013). The question remains: Why?

To try to answer this question, let's start with a quick review of multimode fiber. In the late 1970s and early 1980s, multimode optical fiber was the first fiber introduced into the market. Typically, the fiber had a 50-micron core diameter and a 125-micron clad diameter. Because early local area network equipment used light-emitting diodes (LEDs) as a light source, the industry introduced a larger, 62.5-micron-core fiber, which allowed more light to be captured. This in turn enabled longer transmission distances, at least for the slow 10-Mbit/sec data rates of the time.

62.5-micron fiber was quickly adopted in North America and in other parts of the world as the de facto standard for use in enterprise networks. The information-carrying capacity of that fiber was measured using a method called overfilled bandwidth (OFB), so-named because the light from an LED would flood, or "overfill," the entire core area.

When lower-cost vertical-cavity surface-emitting lasers (VCSELs) were adopted as the light sources for enterprise networks running at speeds of 1 Gbit/sec, a larger core was no longer an advantage. Lasers emit light in a much smaller cross-sectional area than LEDs do, and do not fill even a 50-micron core. When these laser sources began to dominate the enterprise landscape in the late 1990s, 62.5-micron fiber lost popularity because it did not have the capacity to support these higher-speed networks with sufficient bandwidth.

The advent of VCSELs also meant that the OFL method was no longer a good way to measure the information-carrying capacity of a multimode fiber, and a new method called differential mode delay (DMD) was introduced. It allowed fiber suppliers to effectively predict effective modal bandwidth (EMB), often referred to as "laser bandwidth." Because of its larger core and higher numerical aperture (NA), 62.5-micron fiber has a much lower EMB than today's high-performance 50-micron OM3 and OM4 fibers, which were designed and optimized for high-speed lasers.

The migration from 62.5-micron fiber to 50-micron fiber began in the late 1990s, and the advantages of a high-bandwidth 50-micron fiber today are clearer than ever. So back to the original question—Why is 62.5-micron fiber still being installed today? We offer a number of possible reasons here, and explain why they don't necessarily make sense in today's market.

Reason #1: I'm just installing a cable extension using a low-speed network protocol.

Some companies continue to specify 62.5-micron fiber because they are simply installing a passive extension to support additional network elements. This is perhaps the most logical use for this fiber type. However, it is very important to note the words "passive extension." This decision makes sense, for example, if a user is simply connecting one 62.5-micron fiber cable to another cable with no active electronics between the cables.

However, if the network designer is adding active electronics at the end of the existing 62.5-micron cable and connecting the new cable to that active equipment, the newer OM3 or OM4 laser-optimized fiber should be installed. Today's equipment can support much longer links using these new fiber types at speeds of 1-Gbit/sec and higher. When the time comes to upgrade the lower-speed links, the new OM3/OM4 fiber can remain in place, but the older 62.5-micron OM1 cable probably will require replacement.

In general, if active equipment will be installed at both ends of the new cable, OM3/OM4 fiber is recommended.

Reason #2:62.5-micron fiber works well for the network speeds I'm installing today.

Of course, this may be true. But what about your next generation of networking equipment? Enterprise cabling installations are typically installed with the expectation that they will operate for 10 to 25 years. Over that period, equipment can be replaced between two and five times, each time with higher-speed equipment that provides more capability to the network user.

To support that equipment, network administrators need to install cable that is not only cost-effective today, but also provides the ability to upgrade to next-generation speeds. While a 62.5-micron cable can be installed to support a 100- Mbit/sec network, a newer 50-micron OM3/OM4 cable can support the same link and provide support for tomorrow's 10-Gbit/sec and 100-Gbit/sec networks.

Reason #3:It's in my current specification.One reason that generic specifications exist is to provide guidelines for suppliers. However, their value is limited if the specification is not periodically updated to include more-recent improvements in technology. OM3 fiber was defined in TIA-492AAAC-A in January 2003, so ample time has elapsed to "prove in" the technology. Its adoption by a large majority of end users and the lack of new equipment supporting 62.5-micron fiber should be enough to convince the late adopters that specifications should be updated.

Reason #4:62.5-micron OM1 cable is cheaper than 50-micron OM3/OM4 cable.

It's true that OM1 cable is cheaper on a first-cost basis than the newer laser-optimized OM3/OM4 fiber cables. However, installation costs for OM1 cable often are equal to or greater than the cost of materials. If an OM1 cable can only be used for current-generation equipment and must be replaced when higher-speed gear is required, the savings quickly disappear.

In fact, because the existing cable would have to be removed under current code requirements, not only would the network owner have to pay for new cable and installation; they'd be required to pay for the removal of the old cable too. Any minor first- cost savings obtained by installing an OM1 62.5-micron cable would quickly be overwhelmed by the price of future upgrades.

Historically, the macrobend characteristics of 62.5-micron fiber were better than those of standard 50-micron fiber. This led to better cabled attenuations and improved system performance in many cases. However, this is no longer the case. The cabled attenuation of 50-micron fibers is now better than that of 62.5-micron fibers. And with the introduction of bend-insensitive multimode fibers, the macrobend performance of 50-micron fiber is far superior.

The most common and sensible reason to install an OM1 cable today is to passively extend a cable run. While other reasons can be given, the arguments against them are clear, based on the superior performance of laser-optimized OM3 and OM4 fibers. ::

John Kamino is product manager, multimode optical fiber with OFS (www.ofsoptics.com).

View Archived CIM Issues