Clean and inspect:What IEC 61300-3-35 means to you

From the July, 2015 Issue of Cabling Installation & Maintenance Magazine

Improperly cleaned fiber endfaces have operational and financial implications, but can be avoided.

By Brian Teague, MicroCare Corporation

Every cable assembly manufacturer strives to produce pristine ferrule endfaces with zero defects. In the real world, this lofty goal is impossible to achieve. Even the best cable assembly manufacturers have an occasional scratch or pit on the ferrule endface. The purpose of this article is to review the current operational and financial implications of improper cleaning of endfaces, and to suggest improved techniques that will reduce operating costs and improve network reliability.

As a matter of background, the International Electrotechnical Commission (IEC) published in 2009 the latest version of fiber endface specification 61300-3-35. This standard was developed to guide the fiber-optic industry in determining what kind of defects could be on the ferrule endface with no negative performance impact.

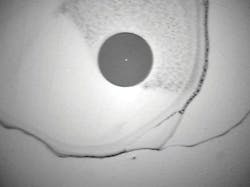

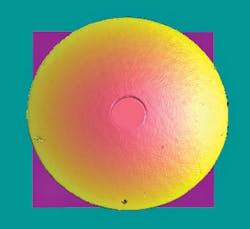

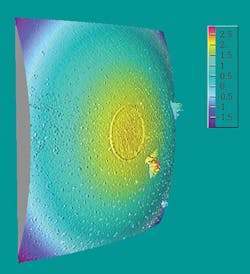

Digital ferrule scopes are commonly used in production and by field installers to inspect ferrule surface quality and comply with this specification. Most digital scopes employ automated, software-driven algorithms to accurately compute the size, area, and location of endface defects. This is an important advancement for the industry; every installer should have this type of gear available to them in the field.

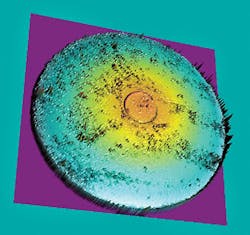

The reason for this concern is that the location of defects relative to the center of the fiber core--the contact zone--is the critical measurement. A 1-µm or 2-µm length can be the difference between having an endface that meets or fails the 61300-3-35 specifications. Even the most experienced operator cannot visually determine if a scratch is 5 µm or 6 µm in length. The use of a digital ferrule scope with automated analysis software set to the IEC 61300-3-35 standard eliminates human error in determining if a defect will negatively impact network performance.

Field installers have limited options for addressing permanent defects like pits and scratches on the ferrule endface. The vast majority of cable assembly manufacturers are doing 100-percent optical testing, so it would be a rare occurrence to get a fiber cable assembly shipped from the factory out of spec.

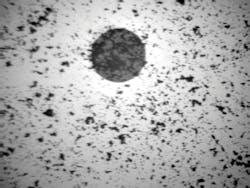

The more common endface defect that field installers will encounter is generally termed “debris.” Debris can be dust, lint, plastic or ceramic particulate, fingerprint oils or a host of other contamination. The industry's best practice is to remove all debris from both connector endfaces using optical-grade cleaning materials before mating the connectors.

It is vitally important to inspect each endface after cleaning and before mating to ensure the debris is removed. At a minimum, failure to remove the debris will cause cross-contamination of the two ferrule endfaces, disrupting the optical signal path. Particulate debris in the contact zone that is not removed, frequently can cause scratches and pits on both connector endfaces. This is the reason Section 5.3 of IEC 61300-3-35 advises installers to inspect the connector endface, clean the endface if necessary to remove contamination, and re-inspect the ferrule. The total inspection process, using a digital ferrule scope, takes less than five seconds for an accurate analysis. Importantly, most modern digital scopes also capture an image of the ferrule endface that helps to document the condition of the endface and ensures the performance of the network.

Static charge problems

Dry particulate has a very sly manner of moving onto fiber endfaces and causing network problems. The symptoms of the problem are perplexing. For example, an operator will clean and inspect an endface, and see a pristine result. Then, the operator will return at a later date and find troublesome dust particles on the endface. How can this happen?

The problem is the process, not the particulate. Dry-wiping cleaning is a common process by well-intentioned installers. Anytime two different materials are rubbed together there is a transfer of surface electrons that creates a static charge. The technical term for this event is "triboelectric charging." The contact friction from the wiping process creates a static charge on surfaces of both the connector and the wipe itself.

Dielectric materials like ceramic ferrules and composite MT ferrules are insulators, not conductors, and they will store the static charge. The voltage can remain trapped indefinitely until a conductive path is created. Any debris residing inside the connector housing quickly becomes attracted to the ferrule endface and is tightly bonded to that surface by what is known as electrostatic attraction (ESA).

Static, as all forms of electricity do, will follow the paths of lowest resistance. Static charge on an endface builds up to the highest levels to the apex of the endface. A common cause of static charge is using a dry wipe or swab to clean connectors in low-humidity environments. This causes particles attracted to the static to migrate toward the contact region of the ferrule, where it causes the most problems. Common sources of static charge caused by contact friction in optical networks include the following.

- Dry-wipe cleaning

- Insertion of inspection scopes and test gear into adapters

- Connector mating

- Equipment cooling fans and fans in the HVAC system

Static charges on the endface will attract and hold particulate debris for days and even months. The debris remains bonded to the endface until the static charge finds a conductive path for it to dissipate. The introduction of a cleaning fluid creates that conductive path, making it easy to physically wipe the debris away. The most effective cleaning process to solve this problem is using an optical grade cleaning fluid. The liquid temporarily creates the conductive medium for the static to dissipate.

Cost implications of not cleaning

Contaminated endfaces such as those described above can be very costly because dirty connectors will slow data speeds and, worst case, bring a fiber network down. What will this cost? A 2013 survey of 67 data centers by the Ponemon Institute, across a variety of industries, found that average cost per minute of network downtime was $7,900. Industries suffering the highest downtime cost included hospitality, public sector, transportation, and media organizations. Installation companies are investing large amounts of capital in the latest network testing gear and personnel training to meet project requirements and customer expectations. But for the networks to operate at their designed reliability, companies must use the proper cleaning tools.

Here's another way to look at it: Labor costs account for 60 to 80 percent of fiber deployment expenses. The cost to roll a truck and crew back to a worksite to repair a network failure is typically around $250 to $400 per incident. Unfortunately, after spending huge sums on test equipment and training, many companies suddenly become overly frugal and choose the cheapest options instead of the most effective options when selecting the connector cleaning consumables to be used on the work site.

Isopropyl alcohol (IPA) and paper-based tissues are the lowest-cost options and most common cleaning consumables. Both are poor choices.

As a cleaning fluid, IPA has a major deficiency; it is hygroscopic, meaning it attracts water molecules from the air even at low relative humidity. IPA packaged in containers that are not hermetically sealed easily can become contaminated by atmospheric moisture as well as the dust particles that float in the air. Dust particles floating in the air will bond with water molecules that are then absorbed into the IPA. After two or three days, the 99-percent IPA that was poured into the container is diluted with floater particles.

Alcohol is also highly flammable and has a high vapor pressure that makes it dangerous to use in areas where there are flames or sparks. Most alcohol-based cleaning solvents also are regulated hazardous materials and cannot easily be shipped by air.

Paper-based tissue wipes are cheap, but cause more problems than they solve. They have a low shearing strength, causing the fibers to separate easily as the operator wipes the ferrule endface. This will deposit debris on the endface.

Some installers use pre-saturated alcohol wipes to clean fiber endfaces and fibers for splicing. Pre-saturated wipes frequently become cross-contaminated. The cleaning fluid will cause the packaging to break down over time. Temperature cycling accelerates degradation of the packaging material, which begins to leach into the cleaning fluid and contaminate the wipe.

Better cleaning choices

Replacing IPA with a precision cleaning fluid engineered for optical device cleaning is a better option for cleaning fibers and connector endfaces. Unlike IPA, high-quality fiber-optic cleaning fluids clean better, dry quickly, and will not leave a residue on the endface. To further minimize the risk of contamination, cleaning fluids packaged in a hermetically sealed, nonrefillable container are recommended. Cleaning fluids and packaging that have been developed and tested specifically for cleaning fiber optics will produce the best results.

Avoid using aqueous (water-based) cleaners. Aqueous cleaners are weak cleaners, slow to dry, and can leave moisture and streaks on the endface. Aqueous-based solutions also are susceptible to freezing in cold climates.

Lastly, about the paper wipes: Make sure to only use optical-grade, lint-free wipes that have high absorbency and high shearing strength. Reusing wipes and cleaning sticks will eventually cause problems related to cross-contamination.

Famed basketball coach John Wooden used to ask his players at the University of California Los Angeles, "If you don't have time to do it right the first time, when are you going to have time to do it right?" Therefore, my final recommendation to installers is: Pick the right cleaning materials that are made for cleaning optical connectors, and do it right the first time. Failure to heed this advice will cost you long term in callbacks, network downtime, and frustrated customers.

Brian Teague is product manager with MicroCare Corporation, which offers Sticklers brand fiber-optic cleaning products (www.sticklerscleaners.com). He has broad professional experience in the fiber-optic industry and has held various product management and business development positions. Teague led the development of mechanical cleaning tools for a variety of fiber-optic connector systems, and has participated in numerous standard-setting committees.