Seismic-activity preparation requires care in product selection

Protecting network equipment against the unseen and unpredictable hazard of seismic activity can be a challenging risk-reward scenario. Investing in equipment that is designed to withstand seismic events has capital-expenditure implications, which are dwarfed by the potential economic loss that can result from a seismic-induced stretch of downtime. In the United States, the general public views California and the San Andreas Fault as the primary - for some, maybe the only - area of seismic risk. However, as Wired magazine pointed out a number of years ago, the Pacific Northwest is one of several other areas at risk for a potential "big one."

"The biggest earthquakes in the country are not in California," Wired's former science editor Betsy Mason wrote in 2008. "A much greater hazard, at least in terms of sheer magnitude, exists to the north of the San Andreas Fault where the ocean crust is being forced beneath the North American continent. Known as the Cascadia Subduction Zone, this 680-mile-long stretch of colliding land mass 50 miles offshore of Oregon, Washington state and southern British Columbia is capable of generating magnitude 9 earthquakes 30 times more powerful than the worst the San Andreas could dish out."

That description, probably intended to shock readers into paying more attention, likely succeeded in doing so. For network managers everywhere, inside and outside North America and at whatever distance from a significant fault line, seismic bracing merits more than just cursory consideration. Giving it due consideration can be a challenge, as several enclosure manufacturers point out in technical documentation they have published.

Multiple specifications

In a white paper titled "Key Considerations for Selecting Server Cabinets for Seismic Areas," Chatsworth Products Inc. (www.chatsworth.com) explains, "Because seismic areas require specific building codes and installation requirements for public buildings to ensure the safety of people and equipment, seismic products that will be installed in buildings must also comply with stringent guidelines. The International Building Code (IBC) states that structures designed according to its requirements are expected to have a very low to no likelihood of collapsing during a seismic event. The IBC also incorporates ASCE 7, Minimum Design Loads for Buildings and Other Structures, developed by the American Society of Civil Engineers (ASCE), which provides guidelines and specific calculations to prevent nonstructural components from sliding or overturning in the event of an earthquake. Note that the state of California has its own set of codes, the California Building Code, which incorporates IBC's criteria and requirements substantially but with few adjustments to accommodate the state's laws."

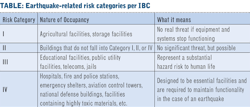

The IBC ranks facilities into four categories based on their earthquake-related risk. A table within this article reflects those categories and types of facilities falling into each.

Chatsworth's white paper explains that in addition to facilities being categorized, components and nonstructural elements - including network-housing equipment like cabinets - also receive numeric ratings or grades per the IBC. Called the Component Importance Factor (Ip), this numeric designation "tells an engineer if there is a need for a special floor design or installation practice," Chatsworth notes. "Depending on the Ip, either 1 or 1.5, building design anchorage, bracing requirements and the design robustness are either more strict or can be more flexible to meet code."

Chatsworth further explains, "IBC compliance takes into consideration the products and their interaction with the entire building. Approval is either achieved through a mathematical equation that compares and extrapolates potential seismic effects to the components installed in a building, or by providing sufficient data showing a component's performance during a strong earthquake [which is referred to as] experience data. Using experience data would require the manufacturer to design the new component with the same specifications. Either way, many variables play into achieving IBC compliance."

Cause for confusion

In a white paper titled "Protecting Data Centers From Seismic Activity," Crenlo (www.crenlo.com) details the coexistence of the IBC's rating systems and the Telcordia Technologies GR-63-CORE Network Equipment Building Systems (NEBS) requirements. That paper notes that the Telcordia requirements came into existence after the AT&T breakup, when competitive local exchange carriers turned central offices from homogenous facilities into heterogeneous facilities in terms of the equipment therein. It says, "Because of the essential nature of telephone communication service, GR-63 requires that in the event of an earthquake, ‘The equipment shall sustain operation without replacement of components, manual rebooting and human intervention.' In other words, an enclosure must provide a level of protection such that the network remains active during an earthquake."

GR-63 was written based on preventing network downtime, Crenlo emphasizes, while IBC is "a broad collection of structural building requirements to prevent human injury and reduce equipment damage during an earthquake … Following the 1994 earthquake [in Northridge, CA], during which more than 40 percent of damages were non-structural, it became apparent there was a need to create guidelines for securing objects within buildings to the floors, walls, or ceilings. In 2000, IBC was created as a guideline to which businesses must adhere in order to receive funding from the Federal Emergency Management Agency in the aftermath of an earthquake. In short, the IBC is a set of guidelines on how to mount objects so that they do not tip over during an earthquake."

Arising from different origins, Crenlo says, the GR-63 and IBC documents understandably have inconsistencies between them. "While GR-63 requirements and testing procedures are consistent across the board, IBC requirements are site-specific, and thus differ from city-to-city, state-to-state, building-to-building, and floor-to-floor. So not only are GR-63 and IBC inconsistent with each other, but there can be major inconsistencies from one IBC-compliant enclosure to the next. Many of these inconsistencies are related to the varying methods of calculation, testing, and certification."

A shaker table test determines if an enclosure will function properly during seismic events. The shaker table simulates an earthquake, up to 8.3 on the Richter scale, and shakes the enclosure front-to-back, side-to-side, and up-and-down at different intensity levels.

GR-63 compliance verification is carried out by independent testing facilities, by putting the cabinet on a shaker table that simulates an earthquake, "shaking in every potential direction at varying levels of intensity equivalent to an earthquake in a particular seismic zone," Crenlo explains. The zones are numbered 1 to 4 according to their intensity. Crenlo adds, "The test is the same for every manufacturer of an enclosure product, regardless of where that enclosure is going to be used or its intended purpose. The only difference between one GR-63-compliant closure and another would be the seismic zone to which it has been tested and deemed compliant."

IBC compliance can be achieved through three different methods, the paper says, "each of which analyzes the enclosure and its contents as part of the entire building system, rather than analyzing the enclosure itself. The fact that there are three varying methods of arriving at the answer, however, is often confusing to the buyer." It is through one of these three calculation methods that an enclosure achieves the aforementioned 1 or 1.5 Ip.

Supplier offerings

As Crenlo points out, the coexistence of IBC and Telcordia GR-63 ratings can confuse a buyer or specifier of enclosures. Manufacturers do what they can to flatten the learning curve for their customers. For example, Crenlo explains it "offers two seismic products - a line of Emcor seismic enclosures and the Emcor IBC kit. The Emcor seismic enclosures are GR-63-compliant enclosures meant for essential facilities, and the IBC kit is a hardware set that can be attached to existing enclosures for easy and affordable compliance with IBC in non-essential facilities."

Likewise Belden (www.belden.com) offers a range of seismic racks and enclosures. The company says these products "feature a robust steel form for hosting servers, switches and network components in earthquake zones. Certified to Seismic Zone 4 requirements, these enclosures have passed vibration and shock testing per GR-63."

Chatsworth also offers a set of seismic cabinets, the Z4 series, as well as seismic two-post racks in addition to a floor anchor kit, "which features four heavy-duty anchors to attach to the four corners of the Z4-Series SeismicFrame Cabinet or Seismic Frame Two-Post Rack," the company says.

Chatsworth Products says its Z4-Series SeismicFrame Cabinet System, shown here, provides a 1,500-pound seismic load rating while accommodating cable- and thermal-management needs.

Chatsworth's paper also briefly addresses the practical question of installing a seismic cabinet. Asking and answering the question, "How difficult is it to install?" the paper explains, "Enclosures in general are heavy and difficult to move on a job site. Seismic cabinets can be almost two times the weight of non-seismic cabinets. Look for a product with transport casters and recessed leveler feet to ease installation. The high-quality designed cabinets feature easily accessible leveler feet to raise the cabinet so that the transport casters can be removed. Be sure to anchor your cabinet directly to the floor using approved anchors. Designs that allow approved alternate mounting locations reduce the impact of site-specific constraints."

Crenlo also addresses installation techniques: "IBC-compliant mounting is generally achieved through the certification of a building engineer. Crenlo works directly with customers and their engineers to recommend minimum requirements for bolt diameter and depth, as well as minimum compressive strength of the concrete floor.

"On the other hand, GR-63 requires that the bolts be a minimum of 3.5 inches long and 0.5 inches in diameter. These are the size of bolts used in testing procedures and thus, are meant to correspond to the real-world scenario. If a GR-63 enclosure also needs to be compliant with IBC, Crenlo can work with the customer and their engineer to determine installation requirements for compliance with both standards.

"When it comes to loading, IBC and GR-63 are actually quite similar. All the standard rules of physics still apply. It is important to remember that the lower the center of gravity, the more stable the enclosure will be. So when loading to capacity, the heaviest items should be loaded toward the bottom and the lightest toward the top. Both standards account for weight, but it is the responsibility of the installer to ensure the weight is distributed as low as possible, as both standards assume."

A rack or cabinet's ability to withstand seismic activity may not be a priority for every network manager. But for those exploring seismic cabinets and racks, the considerations are many.

Patrick McLaughlin is our chief editor.

About the Author

Patrick McLaughlin

Chief Editor

Patrick McLaughlin, chief editor of Cabling Installation & Maintenance, has covered the cabling industry for more than 20 years. He has authored hundreds of articles on technical and business topics related to the specification, design, installation, and management of information communications technology systems. McLaughlin has presented at live in-person and online events, and he has spearheaded cablinginstall.com's webcast seminar programs for 15 years.