Whether it’s fiber-optic cabling, single-pair copper, or anything in between, network gear for industrial environments must be housed and protected.

By Patrick McLaughlin

Forecasts predicting enormous growth for the Industrial Internet of Things market are easy to find. What’s not always as easy to find are cabling and networking solutions to effectively, efficiently outfit an industrial environment for the impending onslaught of data flow.

This article will look at some of the cabling and networking products brought to market to address industrial-connectivity needs.

Transition Networks, provider of networking products and technologies, summarizes the situation on its website: “The network needs of industrial or hardened environments require rugged media converters, hardened Ethernet switches, and SFPs that can operate effectively and efficiently under extreme conditions.

“The proliferation of these technologies has expedited the need for industrial networks that can handle the large volumes of data efficiently, securely, and reliably. Industrial environments mandate a different class of products to handle the extreme temperatures, shock, vibration, dirt, and hazardous locations prone to explosion or fire. Products used in these applications need to be manufactured according to strict guidelines and tested to ensure compliance with industry standards.”

Recently Transition Networks added its Device Management System (DMS) capabilities to its hardened Power over Ethernet Plus managed switches. The DMS software provides management, visibility, diagnostics, and monitoring capabilities.

Optical and PoE

Also recently, Omnitron Systems introduced managed and unmanaged RuggedNet brand industrial PoE fiber switches. The switches “feature four or eight 10/100/1000 RJ-45 ports capable of delivering 15.4W PoE or 30W PoE Plus to all ports, and one or two fiber Gigabit ports,” Omnitron explains. “They are classified as power sourcing equipment and provide full PoE Plus power for up to eight powered devices.

“RuggedNet industrial PoE fiber switches are standards-compliant ruggedized network switches that are temperature hardened to -40 degrees C to +75 degrees C,” the company continues, “and designed for deployments in manufacturing, transportation, energy, and IoT applications. They can be DIN-rail mounted, and feature single or dual DC power inputs and contact closures that can generate alarms.”

Omnitron’s introduction of these switches is indicative of the need within some industrial networks for for fiber-optic cabling’s capabilities, along with PoE. A recent introduction from Belden aimed specifically at industrial networking applications meets PoE needs. Under the Hirschmann brand, Belden offers new PoE/PoE Plus injectors.

“The growing demand for power across IIOT-ready [Industrial Internet of Things] networks necessitates reliable PoE for both legacy equipment and new infrastructure,” said Jurgen Schmid, Belden product manager. “With these injectors, customers can now supply power-hungry devices without needing to rebuild infrastructure.”

The injectors provide increased port density and maximum power without load sharing, Belden adds. “Depending on an application’s needs, two different injectors are available—active, with an integrated power supply, or passive, using an existing external power source,” says Belden. “Both are designed with ease of installation and space savings in mind. These midspan devices can be used to connect non-PoE switches with PoE devices, providing systems with the additional power its devices need without affecting data.”

Single-pair Ethernet

A technical brief recently published by Anixter explains the efforts currently underway within the Institute of Electrical and Electronics Engineers (IEEE) to specify Ethernet over a single twisted copper pair.

“With the rapid growth of IoT and the need to provide cost-effective power, connectivity and security to billions of connected devices, there are gaps that exist in the current Ethernet wiring and application standards that limit the number of devices that can connect to the network via category-rated twisted-pair cabling,” it says. “The most notable gap is that the physical reach of twisted-pair cable cannot exceed 100 meters … Commercial lighting, building management solutions and physical security are examples of solutions that can take advantage of a standard that provides Ethernet-based distance support beyond 100 meters for both data and low-watt power delivery to endpoint devices.”

The Anixter brief then explains, “The IEEE 802.3 formed the 802.3cg Task Force to develop a standard to address device support [over] twisted-pair cabling beyond 100 meters. The standard—IEEE 802.3cg 10 Mb/s Single Twisted-Pair—envisions a unified network based on single-pair Ethernet as an alternative to the hugely fragmented fieldbus landscape.

“Single-pair Ethernet offers a more-cost-effective solution for connecting IoT devices to a network, which is essential in smart buildings, where all systems and devices are integrated with the network,” Anixter says. “While single-pair Ethernet lacks the higher data rate and remote powering capacities of traditional four-pair Ethernet, it provides a more-compact and cost-efficient solution for IoT devices, most of which do not require nearly as much bandwidth and power as the devices using traditional Ethernet.”

Housing it all

A document recently published by Chatsworth Products Inc. (CPI) addresses the reality that industrial networking gear has to be properly stored and protected. The paper “Extending the network into nontraditional spaces: An enclosure selection guide for IT system administrators that support IoT” is authored by David Knapp, product marketing manager and Sam Rodriguez, senior product manager with CPI.

In that document the authors state, “If your business is involved in discrete manufacturing, process industry, transportation and logistics, retail, health care, utilities or energy and natural resources, then you are—or soon will be—adopting IoT … As an IT systems administrator, you will need to extend the network to connect IoT and business systems. This means placing equipment in nontraditional spaces such as warehouses, manufacturing floors and outdoors.”

Knapp and Rodriguez dedicate several pages of the document to the considerations necessary when selecting an enclosure to protect equipment in these environments. “How do you extend the network into nontraditional spaces?” they ask. “Simply stated, the network is fundamentally the same, but the components and equipment must be rated for use in areas that are dusty or dirty, possibly wet, and may experience wide temperature variations. Obviously, this includes the cable and network switches, but you should start with the enclosure.

“In nontraditional spaces, the enclosure provides the primary protection for equipment,” they continue. “The main difference between industrial enclosures and standard IT enclosures is that industrial enclosures are completely sealed when closed.”

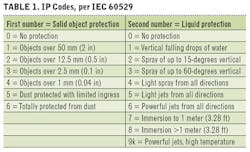

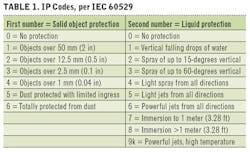

They describe Ingress Protection (IP) ratings as specified in the International Electrotechnical Commission (IEC) standard 60529 Degrees of Protection provided by Enclosures (See Table 1). “The first number identifies the degree of protection against hazardous parts and against solid foreign objects (dust penetration),” they explain. “The second number identifies the degree of protection against ingress of water (liquid penetration). A higher number indicates better protection. IP codes do not address corrosion protection.”

The document also dissects the NEMA (National Electrical Manufacturers Association) 250 standard Enclosures for Electrical Equipment (1000 V Maximum), “which identifies 16 types of enclosures for nonhazardous locations, each providing a different level of protection against dust and liquid penetration.

“There is no direct comparison between IP code and NEMA types, because NEMA standards include additional product features and tests,” Knapp and Rodriguez note. However, NEMA created a conversion table that is generally accepted as the minimum NEMA equivalence to an IP rating.

The authors advise, “When you extend your network into warehouses, manufacturing floors and outdoors, you can satisfy most nonhazardous location requirements by focusing on three enclosure ratings: IP54/NEMA Type 12, IP 66/NEMA Type 4, and NEMA Type 4X … The three enclosures cover the majority of nonhazardous environmental requirements and can be field-adapted with drains, vents, fans or air conditioners.”

From optical switches, to single-pair cabling and Power over Ethernet, to the equipment that houses all such equipment, bringing network connectivity to industrial environments is not a simple proposition—but if prognostications about IIoT market growth are anywhere near accurate, it will be a necessary one.

Patrick McLaughlin is our chief editor.