As fiber-to-the-desk becomes increasingly common, maintainers of local area networks will be forced to confront a new challenge--restoring fiber-optic LANs following an outage.

Larry Johnson, The Light Brigade Inc.

Fiber-optic technology provides the capability to transmit huge amounts of information over long distances. This makes it an ideal medium for long-haul applications such as long- distance telephone trunk lines and cable-TV loops. However, the high bandwidth of optical fiber has also made it useful in campus and premises applications--mostly in backbones, where its information-handling capacity and long transmission distance have offset perceived drawbacks, including high cost and difficulty of installation.

Telephone companies and other service providers have well- established routines for restoration following outages. They need such procedures because their long cable spans often run in exposed aerial locations where cable is strung between utility poles, or cables are direct-buried where they can be cut by backhoes and other digging equipment. Restoration practices, then, are critical to the operation of these long-distance telecommunications systems.

Local area networks (LANs), on the other hand, consist of intrabuilding and interbuilding links covering relatively short distances when compared to the wide-area and metropolitan-area networks usually associated with optical communications. As a result, LANs require different approaches and equipment if the cabling installer or maintainer is to be responsive to emergencies and provide restoration service quickly.

All networks start at a conceptual or design stage. During this stage, you must establish a financial value for the type of restoration strategy you want to assume in providing the physical plant with protection. For example, for networks where high data rates are required, reliability is critical to the success of an enterprise, security is an issue, or priority users must be served, an important design consideration should be route diversity. This means running cable over two different routes, not putting two separate cables in the same duct. This strategy, of course, can raise the costs of materials and construction.

Another issue to consider at the design stage is the types of failures that have occurred in the past. Because history repeats itself, even with network failures, a restoration plan can be built around maintenance and repair records. For example, the following fiber-optic problems can cause a LAN to fail:

1. Broken fibers at connector joints

2. Broken fibers at patch panels

3. Cables damaged at patch panels

4. Fibers broken at patch panels

5. Cables cut in ceilings and walls

6. Cables cut through outside construction

7. Contaminated connections

8. Broken jumpers

9. Too much loss

10. Too little loss (overdriving the receiver)

11. Improper cable rolls

12. Mis-keyed connectors

13. Transmission equipment failure

14. Power failure.

A cursory review of these problems indicates that they fall into several well-defined areas that can be included in the cable-plant restoration plan.

- Patch-panel related--These failures occur around the patch panel (problems 1, 2, 3, 4, 7 and 8). The cause could be improper dressing of the jumpers and cables, improper keying of connectors, or contamination of the connection. Improper cable routing and localized damage are also possible causes.

- System-related--Overdriving or underdriving the optical transmission can cause either total or intermittent network failure (problems 9, 10, 13 and 14).

- Installation-related--Improper bend radius, overclamping the cables and improper rolls of the transmit/receive fibers fall into this category (problems 11 and 12). Installations that are made around previously installed fiber networks can also lead to failures if not enough attention is paid to dressing, termination and cable routing.

- Construction-related--Problems caused by construction-related activities can result from backhoes and other heavy construction equipment. Cables can be damaged in aerial plant due to improper installation techniques, falling branches, automobile crashes, gunshots and lightning. In LANs, cuts through walls and ceilings, improper cutting of abandoned cables, and improper clamping are examples of localized failures that can result from poor cable identification or lack of care by workers (problems 5 and 6).

Once the most common types and locations of fiber-optic network failure have been identified, it is possible to specify the equipment and procedures that will restore the network following an outage.

The equipment that should be available as part of the restoration plan is not extensive, but some of it may be unfamiliar to installers or technicians whose experience has been primarily with copper-wire cabling plant.

- Optical inspection microscope--This device is used to identify poor connector finishes and surface contamination. Magnification can be from 100x to 400x power, with the larger magnification recommended for working with singlemode fibers (identifies problem 7).

- Fiber-optic cleaning kit--Many faults in optical systems are caused by contaminated connectors. A simple cleaning procedure can resolve these problems. Also, remember to keep connectors clean and capped when not in use (resolves problem 7).

- Optical-loss test set--Consisting of a stabilized light source and a calibrated power meter, the optical-loss test set (Olts) is used for end-to-end span tests. The set should be matched to the operating wavelength and connector used in the transmission system. The power meter by itself is the essential go/no-go instrument in fiber-optic troubleshooting. This instrument lets you check power levels at the transmitter, receiver and at any connection point in the system. If the system is well-documented, service records can be used to isolate whether the problem is in the electro-optics or the physical plant. The Olts identifies power levels in problems 1-6, 8-11 and 13. Problem 13 is identified by no power output at the transmitter, or it may show as no power at the receiver. In many of these problems, the power meter may show only a slight decrease in power level. For this reason, accurate records are essential to provide comparisons between existing and historical conditions.

- Visual tracer/fault locator--This device is an inexpensive instrument that transmits visible light through a fiber. The more powerful versions use red lasers operating in the visible spectrum and can locate breaks through many types of jumpers and buffered fibers. White-light versions are also available but do not have the power to locate internal breaks. The visual tracer can be used to identify problems 1-3, 8 and 11, depending on the type of tracer used and the skill of the operator.

- Optical time-domain reflectometer (Otdr)--This is the instrument everyone considers first in restorations, yet it is the most application-dependent. In long-distance networks, where most outages occur away from the equipment at either end of the link, the Otdr is critical for restoration. In the case of local area networks, however, most problems can easily be identified without an Otdr by using the other types of equipment mentioned above.

Once the problem and its location have been identified, it is time to restore the outage--a process that may be more complex than it seems. For example, to complete the restoration you may have to answer basic questions, such as the following:

- Does the faulty cable span have retrievable slack? If so, you can pull the slack back to the fault and create a single repair point.

- Will it by easier or quicker to replace the section than to repair it?

- Will you install connectors or use splices for the repair? In either case, you will need to protect the repair points to prevent future damage to the span. Will you do so by adding closures or patch panels, or by rerouting the cable to other locations?

- Can the system handle the additional losses caused by adding connectors, splices and extra fiber?

- What is the worst location for a problem or the worst scenario that can occur?

- If necessary, can you provide a temporary drop cable until you can make a permanent restoration?

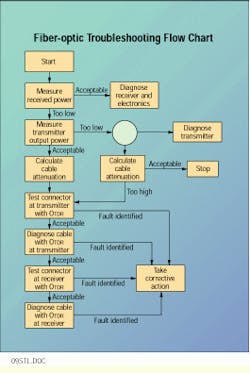

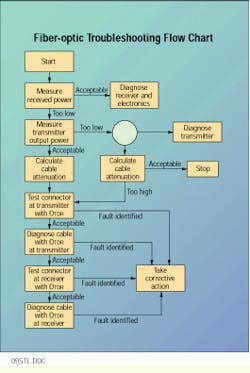

If the physical fiber is identified as the point of failure, you must restore the optical path using a logical and safe procedure. Using a flow chart is one such procedure. Begin by eliminating the transmission equipment as the source of trouble, and then isolate the problem within the physical plant using a step-by-step flow-chart.

Once the problem is isolated, restoration can take place. There are two general scenarios that apply in restoring the LAN. In one, retrievable cable slack is available, and in the other, it is not.

For an emergency restoration where there is retrievable slack, first locate the cable fault and pull spare cable back to the failure point. You must then confirm that the cable break is where it appears to be. Use a visual light source to check each fiber from both ends. (You do not want to have a second cable break one foot away from the first one and not cut it out while restoring the initial fault.)

The area around the fault must then be scouted to find the best repair point and to identify the optimum method to restore the optical fiber. It may be necessary to pull the cable back to a ceiling, floor, post or other location for physical mounting. This location should be noted on your drawings. If a splice panel is added, it should also be labeled and possibly secured. After the cable is repaired, the fiber spans should be retested for loss using the optical-loss test set.

If there is no retrievable cable slack to use during the restoration, it may be quicker to pull a new cable or segment than to repair the damaged one. Also, you should ask yourself whether you should splice or connectorize and how you will protect the joins if you do.

It there is no retrievable slack, you will have to add a section of cable to the span. This will require not only two termination points, but also twice the labor and materials. You must also have a length of fiber cable that has at least the same number of individual fibers as the span of cable being replaced.

The process for retermination is the same when there is no retrievable slack, except that now you have two points instead of one that need to be terminated.

Post-restoration procedures

Once the emergency restoration is completed, it is time to update your records and evaluate the work. Here are some steps you should take as soon as the emergency is under control:

1. Redocument and retest your splices, spans and segments.

2. Adjust your "as-built" drawings. Vaults, closures, splices and slack cable points may need to be added or adjusted.

3. Schedule and conduct a meeting to review all aspects of the restoration:

- What happened? What was the cause of the outage and what impact did it have on your business?

- What did you do well in the restoration?

- What didn`t work, in terms of procedures, equipment, products and staff?

- How can the problems that arose during the restoration be solved?

- How can you improve your emergency restoration plan?

- What needs to be done to rebuild kits and replenish inventory?

Restoration planning is like having an insurance policy: You don`t benefit from it until you have a problem. Because critical circuits for most businesses include all their voice and data lines, emergency restoration planning is life insurance. Businesses will cease to function without their telecommunications and data communications networks. q

Larry Johnson is president of The Light Brigade Inc. in Kent, WA. This article is extracted from his contribution to Fiber Optics Technician`s Manual, published this year by Delmar Publishers.

A flow chart provides a good way of establishing a systematic troubleshooting procedure. In this procedure, the transmitter and receiver are eliminated first as the cause of the problem, and then the elements of the physical plant are examined one-by-one.

Suggestions for Restoration

1. Prioritize your fibers. Most networks have spare fibers. When your system is down, get the priority fibers fixed first.

2. Have spare connectors and a connectorization kit or a mechanical-splice kit available.

3. Maintain a trained crew that knows how to terminate and test the fiber network. Have emergency telephone numbers available for quick access.

4. Have the proper test equipment and tooling for the job.

Using Optical Time-domain Reflectometers

Over the years, optical time-domain reflectometers (Otdrs) have evolved into instruments that, when correctly used, can locate and diagnose many of the problems associated with physical cable-plant failures. However, using an Otdr properly is heavily dependent upon the skill of the operator and his or her ability to interpret signatures.

Another consideration is selecting the device that best fits your application. Most Otdrs are designed for medium to long-distance applications and are limited when it comes to high-resolution applications. Also, most network faults are located at crossconnect panels. The Otdr`s weakness is its inability to find faults within several meters of the front panel.

Many technicians can operate Otdrs for simple go/no-go tests. Otdr skills and knowledge are required the most during restoration, however. Locating the fault point accurately and identifying related stress points require that the technician be highly trained and skilled. The capability to change pulsewidths, work with indices of refraction, read Otdr signatures and printouts, and possibly review overlays from pre-existing test reports all require considerable training and skill.

Otdr operators, for instance, must know when and how to use the various pulsewidths available with the unit and how to override the automatic functions of today`s Otdrs. Using the vertical (loss) and horizontal (distance) scales accurately permits high-resolution fault location. The ability to set cursors and markers correctly gives the operator greater distance resolution.

Remember that fibers from different suppliers require different index-of-refraction settings. Differing wavelengths and fiber sizes will also need to be adjusted for to match the manufacturer`s specifications.

Do You Need Storage Loops?

Networks and the buildings in which they are located must accommodate many adds, moves and changes over their life spans. Designers planning for these needs can, at the same time, resolve one of the many headaches associated with local-area-network cable restoration. This issue concerns retrievable slack, and the problem can be solved with storage loops.

Cable spans designed with slack points enable spare cable to be pulled, while calling for only one termination point. Then, when there is an outage, using quick-connect mechanical splices or direct connectorization allows for restoration with minimal signal loss.

Because most cables within the building are breakout or distribution types, they can easily be reterminated. The main problem with storage loops is how to locate the splice or connection panels or mini closures, the devices that provide strain relief for the cable and physical protection for the splices or connectors. Placement of panels or closures can be above the floor, and either wall- or ceiling-mounted. In most situations, esthetics and size will be key factors. For many users, security and access may also be considerations.

Basic Restoration Strategy

All users of communications systems must have a basic restoration strategy to address what would happen should a network failure occur. Following are recommendations about the kinds of issues such a plan should address:

1. All fiber routes should be properly documented, including both optical performance and physical routing.

2. This should include patch-panel designations, signal type and interconnect routing information.

3. All transmitters and receivers should be documented to their optical transmit and power levels. Receivers should be documented for both minimum and maximum power levels.

4. All spans should be documented for optical loss. This would normally be at both 850 and 1300 nm for multimode applications, and 1300 and 1550 nm for singlemode applications. The documentation should identify the fiber size and manufacturer.

5. If Otdr tests have been performed, copies of the traces should be included in the test reports.

6. If cable has sequential length markings, the difference between the markings tells the actual cable length in meters or feet for each segment. This should be documented.

7. Fibers should be identified and prioritized to permit priority fibers to be quickly restored.

Restoration-equipment Needs

The following items should be on hand when preparing for an emergency outage:

- Restoration kits

- Extra closures and consumables

- Splicing tents, trucks and trailers

- Heaters

- Generators (3.5 kilovolts or more)

- Portable lights

- Folding workbenches

- Safety equipment (barricades, flashers and warning devices)

- Fuel for generators and vehicles

- Spare cable

- Materials list with telephone numbers of suppliers