Tool maintenance saves time and money

Janice S. Wilde, Klein Tools

To protect your investment, know where your hand tools are, keep them in good working order and use the correct tool and the proper technique for the job.

Installers and technicians take their jobs seriously. Investing in the different tools needed to do the job properly can save time and effort and provide professional results. Of course, using the correct tool for the job and working safely can save time and money and can also prevent personal injury.

Tools are job-matched for every type of task; you do not have to improvise to find the correct tool for a particular job. As a professional, you observe rules such as wearing approved eye protection when working with hand tools. The following suggestions about choosing and safely using hand tools may help to reinforce that information.

Pliers

Although some pliers are versatile and can be adapted for many jobs, most are designed for a specific use, such as gripping, turning, binding, cutting, crimping and stripping. To select the correct cutting pliers, remember that the cutting edges are designed to meet according to the way the tool is used; that is, the cutting edges meet first where most cutting is to be performed.

Cutting pliers are available with three types of knife edges: standard, semiflush and full-flush. These descriptions refer to the angle of the outside cutting edges of the knives when fully closed. Each type of pliers makes a specific cut in wire of a certain degree of hardness: for example, standard cutting knives are for hard wire; semiflush for close cutting of medium wire; and full-flush for flat, close cutting of soft wire only.

These basic rules should be observed when using pliers:

- Do not use pliers as a hammer, pry tool or wrench. Using pliers instead of the correct tool risks damaging the pliers, the piece of work or yourself.

- Never push pliers beyond their capacity; use stronger, blunt-nose pliers instead. When you need greater leverage, use pliers with greater leverage, but do not (artificially) extend the length of the pliers` handles. Bolts should be cut with a bolt cutter and larger cable with a cable cutter.

- Do not expose pliers to excessive heat as direct flame on metal can draw the temper and ruin the tool. Cutting pliers are especially vulnerable to high, direct heat.

- Never cut hardened wire with ordinary pliers, unless specifically recommended for this use.

- When cutting wire, do not rock pliers from side to side, and never bend the wire back and forth against the cutting knives, as this can dull or nick the cutting edge. Only cut the wire at a right angle. If you cannot cut the wire easily, the knives may need to be sharpened or you may need pliers with greater leverage.

- Never cut any wire or metal unless your eyes and those of your co-workers are protected by goggles or other protective devices. Always wear approved eye protection.

- Do not depend on plastic-dipped pliers handles to insulate you from electricity. These handles are intended for comfort and a firmer grip only--not for protection against electric shock.

- Do not use pliers or cutting tools on live electric circuits. If there is any chance that the tool may come in contact with an energized source, use only insulated tools marked with the official international 1000-volt rating symbol.

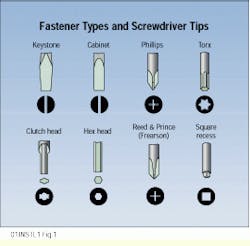

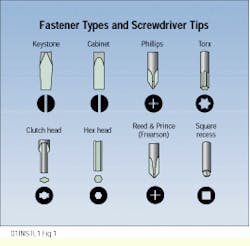

Screwdrivers

The four basic types of screwdrivers are stubby screwdrivers, for working in close quarters; screwdrivers with a square shank to which a wrench can be applied; Phillips screwdrivers; and cabinet screwdrivers, which have a thin shank to reach and drive screws into counter-bored holes. Match the size of the screw- driver to the job, and always match the size of the screwdriver with the size of the screw; the tip should fit the screw slot perfectly.

Screwdrivers are often misused. These tips may be useful:

- Do not use a screwdriver to do another tool`s job; for example, using a driver as a pry bar, scraper or a chisel can ruin the tool, spoil the work and perhaps cause injury.

- Make a pilot hole for the screw and never push a driver beyond its capacity. Use square-shank drivers for heavy work.

- Do not expose a driver to excessive heat because direct flame may weaken and possibly warp the tool.

- Do not use a driver at an angle to the screw; keep the shank perpendicular to the screw head.

- Plastic and rubber handles on a driver are for grip and are not intended to insulate you from electricity. Insulated tools are intended only as a protective measure against shorting out components.

- Always discard and replace damaged or worn drivers.

Wrenches

Designed to keep leverage and intended load (torque) in safe balance, the wrench is one of the most widely used hand tools today. The main function of a wrench, nut driver or socket is to hold and turn nuts, bolts, cap screws, plugs and various threaded parts. Wrench types are available with American standard inch and metric openings. The openings should be smooth and accurately broached for close correct fit to provide a sure, positive pull every time that prevents slipping. The ends of the wrench must be of the correct thickness to provide efficient performance.

Detachable socket wrenches provide an endless combination of handles, attachments and sockets; therefore, you can assemble the correct tool for almost any type of service within the tool`s capacity. Hand socket wrenches are made in many sizes and capacities and have square drivers ranging from 0.25 to 1 inch.

Nut drivers are screwdriver-type tools that, in their simplest form, have a one-piece shank and socket secured in a fixed handle. Socket heads have openings for hex nuts, bolts and screws up to 0.75-inch nut size. Shafts may be solid, drilled part way or full hollow, and can also be magnetic for holding small fasteners.

Combination box open-end wrenches can be used for a variety of jobs because the box opening adds to their versatility and strength.

An adjustable wrench provides a range of capacity in a single tool; however, it is not intended to replace a fixed opening wrench for general service work. Adjustable wrenches should be tightly adjusted to the nut and pull so that the force is on the side of the fixed jaw.

Guidelines for using a wrench include the following:

- Take the time to get the right tool for the job. Using a wrench as a hammer, pry bar or any other tool can damage the wrench or injure the user.

- Always use metric wrenches for metric fasteners and inch wrenches on inch fasteners.

- Do not use a wrench opening too large for the nut or bolt. This can spread the jaws of an open-end wrench and batter the points of a box or socket wrench. A wrench opening that is too large can also damage the points of the nut or bolt head.

- If you use an "artificial" extension on the wrench handle, it can break the wrench; instead, get a larger or different type of wrench to do the job--perhaps a box or socket type.

- To free a "frozen" nut or bolt, apply penetrating oil to the bolt and then use a striking-face box wrench or a heavy-duty box or socket wrench.

- As with most metal tools, do not expose the wrench to direct flame that may warp the tool.

- Always pull on a wrench to exert even pressure--and to avoid injury if the wrench slips or the nut breaks loose. Never push on the wrench, unless absolutely necessary, and then do it with the palm of your open hand.

- Always ensure that the nut or bolt head is fully seated in the wrench jaw opening, and do not tilt an open-end wrench. Use a box or socket wrench on hard-to-reach fasteners. Adjustable wrenches should be tightly adjusted to the work and pulled so that force is applied to the fixed jaw.

Repairing a box, open-end or combination wrench is not recommended. Discard and replace this type of wrench if it has a bent handle, spread, nicked or battered jaws, or damaged box points.

Socket and adjustable wrenches can be repaired by replacing the damaged parts. You should periodically clean and lightly lubricate these wrenches and check for any damage. Discard and replace an adjustable wrench if it has a spread or damaged fixed jaw or a bent handle. Bent socket-wrench handles and extensions and cracked or battered sockets should also be discarded and replaced.

Hammers

A correctly balanced hammer should be the right size and length for the application. For example, when striking another tool such as a chisel, punch or wedge, the striking face of the hammer should have a diameter 3/8-inch larger than the striking face of the tool.

Nail hammers are made in two patterns: curved claw and straight or ripping claw. The face is slightly crowned with the edges beveled, although some heavy-duty hammers may have checkered faces that reduce glancing blows and flying nails. Handles can be wood, tubular steel, solid steel or fiberglass. The last three generally have rubber-tip grips. These hammers should not be struck against metal.

- Ball peen hammers have a rounded, slightly crowned striking face with beveled edges and a round, ball-shaped peen.

- Soft-faced hammers are used for striking blows where steel hammers would damage the surface of the object. Made of nonferrous materials such as wood, rawhide, rubber, plastic, copper, or brass, these hammer heads are cylindrically shaped with two flat striking faces.

- Sledgehammers have crowned striking faces with beveled edges and are used for striking wood or metal.

- Hammers should be used only for the purpose for which they are designed. Misuse can chip the striking face, possibly resulting in injury from flying debris.

- Correct use of hammers includes these basic rules:

- Always strike the hammer squarely, with the hammer strike face parallel to the work.

- Use a hammer of suitable size and weight for the job; for example, do not use a tack hammer to drive a spike or a sledgehammer to drive a tack.

- Never use a hammer to strike another hammer or hatchet.

- Discard any tool that is dented, cracked, chipped or otherwise shows excessive wear.

- Never regrind, weld or reheat-treat a hammer.

The size of the screw and the type of opening it has determine which screwdriver to use.

Janice S. Wilde is a communications specialist at Klein Tools, Chicago, IL.