Are air-blown fibers merits overblown?

Conventional fiber-optic cabling may be the most cost-effective solution for many users.

Allen Dixon

Siecor Corp.

In the rapidly advancing information age, organizations that can best develop and harness information technology enjoy a significant competitive advantage in their respective fields. To gain this advantage, it is becoming ever more critical to build a reliable, durable communications infrastructure. Thousands of installations have proven that structured cabling systems with conventional fiber-optic cable are cost-effective, efficient solutions for private networks--building-to-building, floor-to-floor, and desk-to-desk.

Proven cable designs, connectors, splices, and panels provide voice, data, and video communications solutions worldwide, meeting present requirements and furnishing a migration path to meet future needs as well. Alternative fiber-optic solutions, particularly air-blown fiber (abf) systems, may meet some design, installation, and performance needs of a cabling system, but they do not ensure the depth and breadth of flexibility and standards compliance of proven conventional cabling methods.

abf technology is not new. In fact, several internationally recognized fiber-optic and communications companies have evaluated abf through field and test installations. Each has determined that conventional fiber-optic cable is superior to abf in its ability to meet product and system design specifications, provide uncomplicated installation procedures, allow for graceful modification and upgrade, and simplify termination within acceptable cost limitations.

What is air-blown fiber?

abf systems include three parts: the air-blown fiber, the conduit or pipe for placement, and the associated installation hardware. The 250-micron fibers include a second coating--not found on traditional fibers--made of nylon and foamed polyethylene, which is optimized to provide appropriate blowing and handling characteristics. Conventional 900-micron buffers cannot be used in these installations because they do not have the proper frictional characteristics.

The fiber is available in prepackaged units of 2 to 18 fibers, and in standard fiber types: 50- and 62.5-micron multimode, and singlemode. The fiber packages or units are designed to be blown into pre-placed pipes using a compressed-gas system. The pipes are self-contained conduits containing smaller tubes that accept the blown fibers. Pipes designed for outside installation are 1.2 to 1.8 inches in diameter; indoor pipes are smaller. Pipes are connected by couplers that route the fibers from one continuous pipe to the next. On the ends of each run, each pipe`s tubes also require fittings.

Design considerations

Several years ago, fiber-optic networks were designed to satisfy specific requirements, such as data, video, or voice applications. In recent years, however, the true benefits of optical fiber have been realized, and structured cabling solutions are now designed independent of specific applications. In essence, fiber-optic networks provide a universally adaptable infrastructure.

Several standards, including the tia/eia-568a commercial building telecommunications cabling standard, the icea-s-83-596 standard for fiber-optic premises distribution cable, and the icea-s-87-640 fiber-optic outside-plant cable standard, were designed to ensure that optical cables meet current application requirements, and will meet future requirements as well. However, applying these design and product standards to abf reveals compatibility and specification concerns that you should carefully consider.

First, because air-blown fiber is not really cable, it does not have to meet the cable requirements defined by the Telecommunications Industry Association and Electronic Industries Association (tia/eia--Arlington, VA) or the Insulated Cable Engineers Association (icea--South Yarmouth, MA). These specifications address vital performance characteristics that ensure universal and seamless upgradability for fiber infrastructures. Installation characteristics cited by abf manufacturers are for installations under ideal conditions. Variations in installation performance are not provided for temperatures above or below 68oF, or where humidity is higher or lower than expected. In outdoor applications, temperature and humidity extremes are common. Even in indoor applications, the infrastructure is often placed in less-than-ideal environments, including basements and air-handling plenums that are not air-conditioned.

In addition, no industry-standard mechanical requirements exist for the piping required throughout an abf application. Without clearly defined mechanical specifications, the pipe may be subject to damage that could be undetected during or after installation.

Conversely, manufacturers of fiber-optic cable design, manufacture, and test their cables to validate that they meet the requirements of established standards. Conventional cables are developed to withstand environmental extremes and permit graceful upgrade to higher-speed networks when required.

A second concern is the minimal fiber protection provided by the pipes in an abf system. Manufacturers admit that moisture in the pipes could create problems. No water-blocking agents--such as gels, water-swellable tapes, or powders--are used to protect the fibers within the pipes. Without adequate protection, the fibers can suffer damage from water. For example, delamination can cause the coatings to separate from the fibers, exposing the bare fibers to potential harm. If the water freezes, compression can damage or break the fibers. Conventional cables, on the other hand, are designed to protect fibers from potential mechanical hazards, including freezing, crushing, temperature extremes, lightning, smoke, fire, and ultraviolet light.

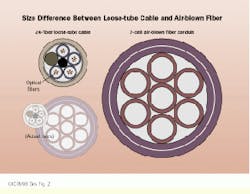

Third, abf pipes require more space than do conventional cables. This characteristic compromises flexibility. In network design, space is typically at a premium, for both outdoor and indoor runs. A long-recognized advantage of conventional fiber-optic cable is its small size. For an outside 24-fiber abf install-ation, a 1.2-inch pipe is required; this pipe has more than twice the outside diameter of either a loose-tube or tight-buffered cable with the same fiber count. A 24-fiber loose-tube indoor/outdoor cable has an outside diameter of 0.45 inch; riser tight-buffered cable is 0.5 inch in diameter.

Fourth, the pipes required for an abf installation must be placed in pathways for existing applications as well as for future use. Installing spare abf tubes compounds the problem. With the pipe in place, the conduit cannot be used now or in the future for another application. If any changes are made to the network design after the pipes are placed, those pipes must be taken out for replacement. Rearrangement within a building is common, particularly in horizontal applications in which open-system offices are typical. To build such flexibility into an abf system, you must install larger pipes that you may or may not use. With conventional cables, however, system re-arrangement is much simpler, even with cables that are already connectorized.

Finally, when designing a cable system that features interbuilding cable runs, designers must give consideration to transitioning the abf system from an outdoor run to meet the riser requirements of an indoor run. The National Electrical Code of the National Fire Protection Agency (Quincy, MA) requires that the infrastructure meet flame-retardant specifications (UL-1666 for riser and UL-910 for plenum). This transition requires splicing the tube cable at the entry point, which requires additional hardware. Conventional cable technology has advanced to the point where some optical cables meet the environmental requirements of outdoor applications as well as the flame- and smoke-retardancy requirements of indoor cable. With these cables, transition splice or connector points and their associated costs can be eliminated (see "Indoor/outdoor cable turns the corner," January 1998, page 39).

Installation considerations

Installing conventional fiber-optic cables has become easier over the last several years because cable, connector, and splicing products have improved and standardized installation procedures have been established. Contractors nationwide that have installed copper-cabling systems for years have now been trained and certified to install fiber-optic networks. Some private network users have trained their own staffs to terminate fibers for moves, adds, and changes. Fiber handling and termination are no longer considered complex and cumbersome.

abf systems do not offer this simplicity. First, extensive up-front installation is required for abf systems. Initially, installers must place the specialized conduit throughout the network. Network planners must carefully determine paths, and installers must place and connect the necessary pipes. The installer then must blow the fiber into the tubes using installation equipment including a blowing head, a control unit, and compressed gas. Anyone who will operate the blowing head must be trained to do so. Of course, specific care must be taken when handling compressed gas. The installation system requires a significant amount of room--a luxury typically not afforded during a cabling installation.

On the other hand, conventional fiber-optic cable is pulled through a planned route and can be terminated after it is pulled or left dark for future use. Termination requires a few tools and less space than the abf installation equipment.

In outdoor environments, abf systems limit installation flexibility because the fibers can only be routed through the abf conduit. In outside-plant applications, conventional cables can be directly buried, placed in conduit, or hung aerially. Because abf installation requires two steps--tube placement and fiber installation--the time-saving merits proclaimed by abf proponents are questionable.

Another installation consideration is that air-blown fiber is not designed for preconnectorized cabling. Despite the size of the conduit, it is not designed to accept connectors, nor can the system blow connectors with the fibers. Consequently, installers must splice or connectorize the fibers on both ends once the fibers are in place. Installers also must fit the air-blown fibers with fanouts before they can be connectorized, or splice pigtails into place.

You can install conventional fiber-optic cabling with connectors factory-terminated on one or both ends of the cable. This solution can simplify installations when the cable length is known. Once the preconnectorized cables are pulled in place, the installer plugs the connectors into the hardware and the system is operational. Further, conventional tight-buffered indoor cables do not require fanouts for termination. The installer strips the buffer from the fiber using a conventional stripping tool, installs the connector, and places the termination in a fiber panel.

Also consider that placing air-blown fiber requires special handling. The fibers incorporate a 250-micron-thick coating for protection, so it is vital that installers handle the product with care to avoid breaking it. abf manufacturers claim that fiber reusability provides flexibility for users. If a fiber is not needed, it can be blown out and placed elsewhere. While this is true, installers and technicians must take care when handling these fibers so the coating is not damaged. Also, the fiber can only be reused if it is placed in a run that is no longer than, and meets the same optical performance as, the original installation.

Conversely, conventional fiber-optic cables are designed to withstand rugged treatment. Outdoor cables have been struck by lightning, hit by pellets, and run over by machinery, and have continued to meet operating specifications. Likewise, indoor cables have continued to perform after having been accidentally dropped several stories down riser shafts, and run over by equipment.

A final installation consideration is that no standards exist to specify an abf installation. Such a standard would ensure that the products are adequately checked following installation and are tested to meet design specifications. For example, before blowing fibers it is important to verify the continuity of the conduit. Conventional cabling installations, on the other hand, are measured against established standards.

Cost comparisons

If you are thinking about installing an abf system as your network infrastructure, carefully examine costs. abf system manufacturers indicate their method provides for deferred investment. However, users of abf systems pay to have the conduit system laid throughout the network--perhaps even where it will not be used. Conduit must be laid for all possible fiber-drop locations. This conduit not only represents a capital expenditure, but it also occupies space that could otherwise be used for other purposes. The abf pipes alone--excluding the specially coated fibers--cost more than conventional fiber-optic cable. A 4-cell, all- dielectric pipe for outdoor installation costs about $1.40 per foot. So for a continuous 1000-ft run, the price for a 24-fiber abf solution is about $34,000, excluding specialized hardware, connectorization, and preparation time. A comparable installation using conventional outside-plant cable would cost about $28,000.

Likewise, the price of air-blown fiber is more than that of conventional fiber-optic cables. The fiber units alone--excluding the conduit--cost an average of $1.32 per fiber-meter. This is significantly higher than the cost of fiber-optic cables today, and there is no guarantee that the price of abf-system fiber will level or decline should you decide to defer purchasing it.

Air-blown fiber has been positioned as being more economical because of cost reductions that result from minimizing fiber splicing on each floor of a building. Installations in accordance with tia/eia-568a call for home runs of cable to each floor. Conventional cable installations that follow this standard are more economical and require less space than abf installations.

In addition, the price associated with the actual installation is worth considering. An abf installation requires specialized skills that are not necessary in conventional cabling installations. Typically, a specially trained technician will have to operate the abf installation equipment. Then the fibers must be fanned out, connectorized, and placed in abf-specific hardware for storage and protection. This differs from a conventional cabling installation, where once the cable is in place, a network technician can field-terminate fibers when they are needed without disrupting business activity.

When network design, installation, and cost considerations are weighed, the conventional fiber-optic cable solution provides a cost-effective, manageable, and upgradable infrastructure. Installations of abf systems require careful planning and additional investment, as well as specialized equipment and specially trained operators. After installing the air-blown fiber, you must deal with special tubes, fanouts, and procedures to complete the fiber system. Although improvements in cable design and installation technology are always welcome, it is important that users evaluate these changes properly. Responsible users will ask for detailed installation quotations from each supplier to compare immediate and future costs before making a decision.

The pipes through which air-blown fiber is routed are joined with couplers.

In an outside-plant application, traditional tight-buffered or loose-tube fiber-optic cables occupy less space than air-blown fibers and their pipes.

Allen Dixon is product marketing specialist for Siecor Corp. (Hickory, NC).