Managing more than one million feet of cable

J.D. Edwards`s cable-management team designs a prototype structured-cabling system.

Scot Michael Howard

When it comes to cable management, even the simplest alterations to a company`s network support center can present a host of problems. Potential pitfalls abound in practically every aspect of cable management, from developing the concept and design to ensuring that mission-critical applications are disrupted as little as possible.

What if you were charged with the design and implemen-tation of a structured-cabling management solution for a 200,000-square-foot facility that has some very unusual cabling requirements? What if that plan had to work equally well throughout a 53-acre technology complex--said to be the largest complex in Colorado--and that solution would become the standard in at least 46 satellite facilities throughout the world? That was the challenge that faced J.D. Edwards, a leading enterprise business-software developer, when it created a cable-management plan for its new corporate facility in Colorado`s Denver Technology Center.

J.D. Edwards assembled a team of vendor partners, created a worldwide internal corporate standard, and used copper cabling from the backbone to the desktop as the transmission medium. The result was an innovative, highly functional, and cost-effective cable-management system for an estimated 1.25 million feet of cable laid at the new facility.

Before the cabling installation actually started, it was determined that traditional backbone and horizontal cabling standards would be inadequate to handle the anticipated communications needs of more than 800 employees and managers to be housed in the new corporate facility. "We needed to design a communications network-support infrastructure that would accommodate a company currently experiencing 40% annual growth and that would become the standard for our 46 remote offices," explains John Williams, J.D. Edwards`s technologies facility manager. The design and selection team working with Williams consisted of a project implementation group for implementing prescribed cabling standards into the new facility and an IT management group for evaluating and writing the company`s technology specifications.

Williams says the company relied on what he calls "proven cable-management common sense," designing a cable-management structure that not only accomplishes the company`s goals cost-effectively but also provides a smooth upgrade path without technological overkill. The cabling infrastructure would need to support independent technologies and multiple vendor products, while complying with the tia/eia-568a Commercial Building Telecommunications Cabling Standard.

Copper versus fiber cabling

As the company searched for a fiscally responsible solution to its cable-management needs, one of the most important elements of J.D. Edwards`s analysis was determining how much bandwidth employees would need and the best way to provide it for the diverse tasks--business-software development, product marketing, accounting, technical support, and training--they would be performing on their PCs at the new site. Bandwidth requirements had to be tailored to each worker`s specific applications.

Even though Williams and his planning staff knew that workers initially would be communicating via Token Ring and 10Base-T Ethernet protocols, it was clear that they would have to plan for gigabit data and voice transmission in the not-too-distant future. Probably the most significant question Williams and his team considered was whether to use copper or fiber cable to meet the company`s present and future communications needs. It was a difficult choice for them, and they weighed several possibilities that fit within the cabling configurations designed by Williams and his team.

The configurations included intermediate distribution frames (idfs) on opposite ends of each of the facility`s six floors, with the main distribution frame (mdf) in the basement. Several of the innovative elements in the design grew out of Williams`s concern with two major areas:

- distribution limitations--how to easily and effectively provide cable where needed,

- future flexibility--simplifying moves, adds, and changes as workgroups evolve.

To accommodate both existing and incremental technologies to the network infrastructure, the team designed and implemented 18 fixed-location power poles per floor, in addition to cubicle distribution frames (cdfs) and a Holocomm Systems (San Diego, CA) vertical-panel control module integrated with a Pleion (Santa Ana, CA) furniture system. Together, these elements made it possible to run cable in 2-foot increments, making it easier to run cable from the ceiling, down the power poles, to the cdfs, and out to individual users.

This design solution would allow patch cords to be cascaded down and through the Pleion panels to each user`s desktop. Alterations to the communications infrastructure could be made in minutes because changes would be handled at the panels instead of by rerouting and running new cable to the appropriate idf and then to the mdf. This cable-management plan reduced the length of cable runs from telecommunications closets to about 70 feet each, roughly one-half to one-third the length of typical cable runs in a building the size of J.D. Edwards`s new facility.

In choosing the type of cable to fulfill these design plans, the design and selection team discussed the fact that fiber provides flawless transmission at very high speeds, voice and data communications over the same cable, and unlimited possibilities for future high-speed transmissions. Yet, they determined that fiber would cost about $35 more per workstation and would be more difficult to install than copper cabling.

Futureproofing needs

So for the horizontal cabling runs from the facility`s idfs and cdfs to the workstations, they decided that enhanced Category 5 unshielded twisted-pair (utp) cable and associated hardware would satisfy the anticipated 1-gigabit bandwidth requirements. They determined that it would be a long time before PC users at the facility would need the benefits that fiber provides to the desktop. But to cover any futureproofing needs, the team decided to install multimode fiber cable in the risers for data-transmission applications, with Category 5 cable as backup. For voice applications, they would install Category 3 utp cable from the mdf to the idfs.

In addition to determining cable types, the team decided which cable-management products and electronics to use. Since this facility`s cable-management plan would become the standard for all current and planned J.D. Edwards facilities worldwide, it was important to consider international suppliers.

Auditioning the best solution

To determine which companies produced the most appropriate products for J.D. Edwards`s installation, the planning team conducted a side-by-side comparison of various products for structured cabling systems. There were traditional as well as innovative elements in the cable-management plan on which these prospective vendors were invited to bid. Vendors completed an idf mock-up, fully loaded with equipment. This method eliminated any potential problems concerning compatibility or questions about how the final installation would look. J.D. Edwards learned, for example, that changing from non-patch-panel to patch-panel connections would increase installation costs. The goal was to convert to patch panels without paying more than 10% above a non-patch-panel solution, which the company was able to achieve.

For rack systems and cable-management products, the company chose Chatsworth Products Inc. (cpi--Westlake Village, CA). "In all of the product comparisons," says John Musial, J.D. Edwards project implementation group member, "cpi`s CatRack high-density standard racks provided the best base to support system solutions. I have been working with CatRack systems for the past several years so it was just a natural progression to go with cpi for our installation." The Siemon Co. (Watertown, CT) was selected to supply the cabling systems, and Denver-based Lewan & Associates, a solution integrator, was chosen to do the actual cable installation, working with local supplier Graybar as well as with Siemon.

J.D. Edwards`s cable design and management plan included a high-density matrix that would allow the maximum number of people on each floor, with the ability to relocate them easily and save the company approximately $500,000 over five years. Another money-saving part of the plan was to securely suspend a messenger wire support system under fixed cable trays along the ceiling. Wiring similar to that used in electrical fences was tautly ratcheted to the ceiling. The enhanced Category 5 cable was then secured to the wiring using simple wire ties. Although the messenger wire support system was not easy to install, this method could maintain cable integrity over long runs.

The J.D. Edwards cable-management plan also called for the use of Category 5 harness cables. Data lines are patched to the equipment, which is located in a separate cpi rack system. This clean separation from the equipment eliminates the need to touch sensitive equipment when making moves, adds, and changes.

Speed counts

Besides the need for an innovative cable-management design that would be both cost-effective and easily implemented in other sites, one of the most significant elements of the project was speed of installation. An aggressive project schedule permitted Lewan & Associates only five months to lay the cable, wire the closets, and complete the installation. At times, Lewan technicians worked in an unheated building, which was protected from the elements only by heavy plastic drapes.

"The J.D. Edwards installation presented some unique cabling challenges, in addition to the speed at which it was carried out," reports Lewan operations supervisor Mac McGinnis. "We installed more than 1.25 million feet of enhanced Category 5 cable throughout the facility, completing an average of one floor per week. That`s about twice as fast as a normal installation schedule!"

The use of cpi rack systems was important in getting this complex design and implementation project completed correctly and on time. "We have been using CPI rack systems and cable-management products for more than three years," explains Craig Cottrell, Lewan`s project manager for the installation. "Time was a critical factor in this project. cpi`s products and attention to detail made our job move more quickly and made it much easier."

"It`s the little things that make or break you in a major installation project like this," says Musial of J.D. Edwards. "Installation time is significantly reduced when parts fit together perfectly, when corners are smooth so installers don`t cut their hands, and when the cable runway allows a quarter-inch space so that fingers can fit easily between cable ties and cross sections."

Cookie-cutter cable management

J.D. Edwards achieved an innovative and effective cable- management solution in its main building, but what about the company`s attempt to maintain consistency in the plan for the additional corporate buildings on its 53-acre campus and at the 46 remote offices?

By standardizing on the cabling systems of The Siemon Co. and the network structural support of cpi, Williams believes that the new facility`s cable design can be duplicated for the company`s entire network infrastructure and for its more than 3500 employees worldwide.

All of the Edwards idf and mdf cabling installations worldwide now look exactly alike. The company`s cable- management plan allows for fast, easy, and economical solutions to system problems and alterations today and in the future. "Let`s say one of our remote sites needs to add a new work- station to its communications infrastructure," says Musial. "Any employee at that site can contact our Denver headquarters and talk with a corporate cabling technician, who in turn, can walk into one of our local idfs and tell the employee exactly where to patch the cables at the remote facility."

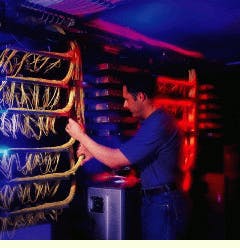

A cabling technician inspects structured cabling-management solutions at J.D. Edwards`s new corporate facility in Denver, CO.

A technician checks overhead cabling that connects intermediate distribution frames on opposite ends of the room with a cubicle distribution frame.

Installed on each of the 18 fixed-location power poles per floor, cubicle distribution frames and a Holocomm vertical-panel control module simplify moves, adds, and changes.

The main distribution frame room, or network center, is configured with cpi`s CatRack high-density standard racks and universal cable runway to manage more than 1.25 million feet of Category 5 and Category 3 utp cable.

Scot Michael Howard is a writer with Alper/Alper & Lopez Inc. (Los Angeles, CA), the agency of record for Chatsworth Products Inc. (Westlake Village, CA).