Nothing runs like this network

A wire and cable management system provides flexibility for the corporate offices of John Deere Credit.

Tony Eschmeyer/The Wiremold Co.

John Deere, whose self-polishing plows opened the prairie to large-scale farming, also revolutionized farm-implement manufacturing by producing plows in quantity for subsequent sale, rather than building them one at a time on custom order. Such an approach required credit. In fact, according to company lore, John Deere financed the second plow he ever built. Today, John Deere Credit plays a major role in agricultural financing through equipment leasing loans, operating lines, and cash-flow management. It also provides financial solutions in the commercial business, grounds care, and personal markets.

The new 240,000 square-foot world headquarters of John Deere Credit in Johnstown, IA consists of two three-story buildings linked by a full-height atrium. An open and flexible environment was a high priority for the company's planning team. "We are constantly looking for ways to improve our product mix-a process that can mean reorganization and shifting people around," says Merlin Siefken, director of facility planning.

Wire and cable management

Openness and flexibility guided important decisions about the building's wire and cable management infrastructure. According to Dick Elskamp, manager of office administration, "We're very meeting-intensive, with a lot of teams and collaborations in groups. They like to get together in an open environment." In each building, a central core is surrounded by open office space with modular Herman Miller (Zeeland, MI) furniture. The north building, which also houses a cafeteria and other support functions, has space for some 200 employees. Between 600 and 650 people work in the south building.

The design team-which also included John Mayer, manager of voice and data communications, and John Ferguson, information-technology technician-considered a shallow raised floor system, but was concerned about durability and acoustics. They also determined that a full raised floor would add too much height to the buildings. The space required to accommodate telecommunications closets was also a concern. "The design of the building meant we either would need more data closets or much larger ones," recalls Siefken. "And there was the challenge of getting cable to the workstations."

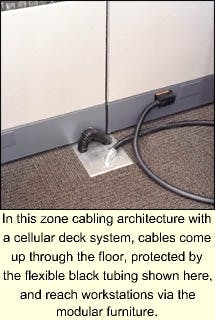

A N-R-G-Flor Celluar Decking System from Walker Systems Inc. (Williamstown, WV)-a Wiremold Company-offered capacity, flexibility, and a cost savings, since the deck is part of the structural reinforcement for the concrete slab. But according to Mayer, "One problem is that the feeder trenches for a large cellular deck system can get congested with home-run cabling, so there can be a capacity issue near the communications closet."

A zoned solution

The solution was to alleviate cable congestion by dividing floor space into zones, each with its own compact communications cabinet integrated with the cellular deck, trench wire and cable management system. Each floor has 10 zones, with a "zone point" adjacent to a support column. Twelve-strand fiber-optic cable and 100-pair standard voice-grade cable are routed overhead in SpecMate cable tray. Each side of a floor is linked by a fiber-optic cable feed to the computer room, located in the basement of the north building. In addition, the two sides of each floor are also connected by Category 5E unshielded twisted-pair (UTP) cable that provides 100% redundancy in the event that the primary cable fails.

"Each floor has two distribution closets," says John Deere Credit's Jim McClurg. "A 24-fiber cable runs from the computer room to each distribution closet. These cables take different paths to each floor, so that a cut cable will not disable an entire floor. One distribution-closet cable travels through a tunnel between wings, and the other closet's cable travels through underground conduit.

"There is also a 24-fiber cable between the two distribution closets for redundancy, so that in case one of the cables is cut, there is a path to the other distribution closet."

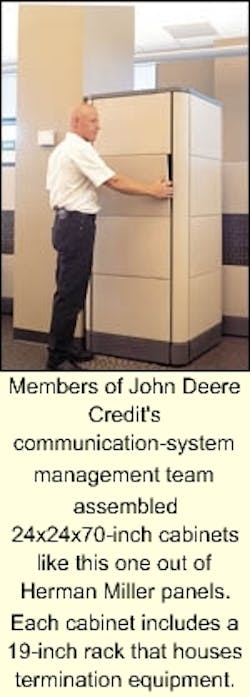

From the overhead cable tray, cabling for each zone runs down to a 24x24x70-inch communications cabinet that the John Deere team assembled from Herman Miller panels. These cabinets include a 19-inch rack that houses fiber and copper termination equipment. "Cisco now has smaller switches, so you can have multiple locations, rather than large telecommunications closets," says Mayer.

These cabinets are situated directly over Walker intermittent bottom trenchduct that feeds cabling to workstations and conference areas through the N-G-R-Flor cellular raceway system. Because of the limited number of workstations in each zone, trench capacity is not an issue. The N-G-R-Flor system provides flexible access to power and data-communications cabling through recessed and furniture-feed activations.

Each workstation has two 8-pin modular data connections and two RJ-11-style voice connections. A double faceplate also contains a blank for adding ports. Conference rooms are located directly over ducts, so additional voice and data capability can be added quickly. In open collaboration areas, a data tower plugs into a floor jack so data, voice, and power are easily accessible. An area known as "the campground" encompasses six workstations and a meeting space so visitors can get right to work. Booths in the cafeteria are also tied into voice and data networks.

Workstation flexibility

The zoned system has the effect of breaking a large open office space into more manageable areas, while providing total flexibility at the workstation. "If one workstation needs a second computer, or a printer, or a fax machine, it's already wired," says Mayer. "I just run a patch cable at that zone point. If a specific area has to tear its furniture down and reconfigure, we're only working with 30- to 50-foot runs, not 150-foot runs. And the only area we have to disturb is that particular area."

Zoned cabling also allows for technology upgrades. Says Mayer, "If the majority of the business can operate on 100-Mbit/sec Ethernet, we'll leave them like that. But if we have one area, such as imaging, that needs to go to gigabit speed, I can go to their zone, install that new piece of equipment, and plug their desks into that equipment. I don't have to retool the whole company."

Power is also distributed by zone, with each column housing a breaker panel. The flexible system also allowed John Deere Credit to effectively manage its backup power system. "To keep this building completely up and running during loss of street power would be a phenomenal cost in terms of the size of generators," says Elskamp. "We probably would need two generators."

Instead, the zoned duct system allows dedicated emergency power to be provided only where it is mission-critical. "If we have an individual who is performing an essential process, their equipment is connected to the dedicated circuit," says Siefken. "We can move these circuits around from one station to another, so if someone's function becomes critical, they don't have to change to a new location."

The new John Deere Credit headquarters supports a nimble organization that moves quickly in response to changing global conditions. Worldwide, all offices are equipped with identical systems. But the new headquarters sets the standard for flexibility. "The objective is total flexibility at the workstation without installing new jacks or incurring any additional labor costs associated with new home runs," says Mayer.

According to Siefken, it will take only a few reconfigurations of workspace to recoup the investment in a flexible wire and cable management system. In fact, it began to pay off even before the facility opened. "Just before we were going to move in, one business unit and one division were created," he says. "We are able to change the space to accommodate them."

Tony Eschmeyer is product business manager with The Wiremold Co. (W. Hartford, CT).