Phil Brown

Jamie Kelley

Communications Products Inc.

Problem

In many older buildings, existing bore holes through the walls of telecommunications closets and firewalls are filled or they do not exist. A cable installer can spend hours drilling and sleeving through masonry and rebar-enforced walls, only to be left with ragged edges that must be patched and restored.

Solution

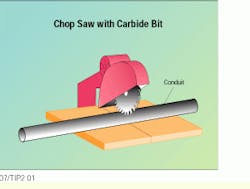

By using the proper tools, the installer can minimize time and produce neat, uniform holes of the proper size that can then be sleeved. Two power tools are required to maximize efficiency and produce uniformity. One is a power chop saw equipped with a carbide blade. Another is a heavy-duty, right-angle grinder equipped with a deep-set, dry-concrete hole saw.

Procedure

Inspect thoroughly the area to be drilled, noting the location and size of all required holes. Then determine the number and size of the sleeves needed for the holes. (At this time you may also want to forecast the sleeving needs of projected future cable runs and make recommendations to the customer.)

1) Using the chop saw with carbide blade, cut all conduit to the sleeve length you have measured, leaving additional length for the placement of connectors and bushings at each end of the sleeve.

2) File the cut ends of the conduit smooth, and install the connectors and bushings.

3) Set up the right-angle grinder with dry hole saw. Select an oversized dry-concrete hole saw to permit easy placement of the sleeve through the finished penetration.

4) Drill the hole through the wall at the selected height and proper location. Make sure that an assistant with a basket or bucket is located opposite the hole being drilled to catch flying debris.

5) Remove the connector and bushing on one end of the precut sleeve, and slide the sleeve through the hole. Plug the gap between the wall and sleeve with cement or other suitable material. Replace and tighten the connector and bushing.

6) Allow the cement to dry.

7) Install cables feeding through the wall.

* Firestop the penetration and touch up any blemishes to the paint or wall as required.

A chop saw with a carbide tip cuts the conduit used for sleeving to the proper length.

A right-angle grinder with a dry-concrete hole saw is used to drill the penetration through masonry or rebar-enforced walls.

Phil Brown, registered communications distribution designer (RCDD), is director of cable engineering for Communications Products Inc. (Indianapolis, IN).

Jamie Kelley is a project manager at the company, which specializes in systems integration.