Barbara E. Thompson

The TIA/EIA-568A commercial building telecommunications cabling standard recommends using SC connectors in new fiber-optic cabling systems. Although the ST-style connector will be grandfathered in existing applications, the SC will be the connector of choice for upgrades and new applications. The TIA/EIA recommendation was based, in part, on the fact that the SC connector is suitable for fiber-to-the-desk applications, is easy to install and it can be duplexed.

These 568SC connectors (as the TIA refers to them) are recommended for use in backbone and horizontal cabling and for all connecting hardware from the main crossconnect to the telecommunications outlet for singlemode and multimode fiber-optic cable systems. The TIA/EIA-568A standard also recommends color-coding SC connectors--beige for multimode and blue for singlemode fiber-optic systems.

The SC connector was originally designed by Nippon Telegraph & Telephone in Japan. Its name comes from "subscriber connector," which describes the connector`s original application in telephony.

The function of a fiber-optic connector is to form a remateable connection between two fibers. This is generally accomplished by physically aligning the cores of two mating fibers. Like other fiber-optic connectors, the SC is built around a cylindrical ferrule that holds the fiber and mates with an interconnection adapter or coupling receptacle. Unlike other connectors, however, the SC has a push-pull latching design: You push the connector to latch it into place; no need to turn it as with other connectors. The SC connector body surrounds the ferrule so that only a small part protrudes, protecting the ferrule from damage.

On an SC connector, the strength members are secured to the connector housing, not to the ferrule. A slight pull on the cable, therefore, will not pull the ferrule out of optical contact with the interconnection.

"It`s pull-proof by design," says Sandy McWilliams, fiber-optics division product manager at ADC Telecommunications (Minneapolis, MN). "When you pull on the cable, the force is transferred to the coupling mechanism, not the ferrule, so physical contact is not lost."

According to Donna Ballast, telecommunications analyst at the University of Texas at Austin, and author of Ask Donna, "The SC connector is rated to withstand a minimum of 7.5 pounds tensile pull at 0 degrees and 5 pounds at 90 degrees."

Simplex and duplex applications

Another important aspect of the SC connector is that it can be used for duplex (2-fiber) applications, where one fiber carries information in one direction and another fiber carries information in the other direction. For example, a computer workstation with a fiber-optic connection to the network contains a transmitter and a receiver. Duplexed connectors permit a single connector to plug into both the transmitter and receiver.

To make a duplex connector, you terminate the fibers in two SC connectors and then use a clip or yoke to hold the two connectors together. The simplex SC connector and adapter are keyed to ensure the orientation of one fiber to the other (polarity). The SC connector, therefore, can be used in simplex and duplex configurations. It is small enough so you can plug two simplex SC connectors into a duplex outlet, thereby making it easier to use in the telecommunications closet.

"With duplex SC connectors, there`s no confusion on the transmit-and-receive; there`s only one way to mount it," says Mike Pellegrini, quality control and project manager, Communications Technology Services (Northborough, MA). "With the SC, there`s no twisting, so it won`t scratch the fiber and potentially cause a problem."

Most SC connectors have the same physical dimensions and latching mechanism. They differ, however, in ferrule material, price and installation time and whether they are field- or factory-installable. In addition, installers may prefer to use epoxy, hot-melt, no-adhesive, anaerobic adhesive, ultraviolet-curing, or crimp types of connectors.

How to choose

The material composition of the ferrule can be ceramic, metal or plastic, with zirconia or ceramic being the most prevalent for SC connectors.

"There are a variety of ferrule materials but we use ceramic because we are concerned about cleanliness," says McWilliams. "Every time you mate and demate a nonceramic ferrule, there`s a chance you`ll get shavings on the ferrule. Usually, if you find low-cost connectors, they have a plastic- or metal-type ferrule."

Price is another issue. "Because millions of ST connectors are installed and several vendors manufacture them, their price has come down," says Dan Silver, market development manager, 3M Telecom Systems Division (Austin, TX). "But the volume of SC connectors is not yet there, so they tend to be a little more expensive."

The Telecommunications Act of 1996 will affect the telecommunications industry, resulting in increased demand for SC connectors. Contractors must also consider installation time as a cost issue.

"One of the things that installers will look at when they have to do a job is how many hours it is going to take," says Alan Sappe, marketing services coordinator, AMP Inc. (Harrisburg, PA). "If they can save on the number of hours, that`s the product they will choose."

In addition, you need to take other variables into consideration. For example, where are you doing the termination? Are you in a clean working environment? Is it easy to get to the cable? You also have to consider what associated products you will need for the SC connector.

"We`ve been using ST connectors for fiber," says Pellegrini, "and when we first had to do an SC connector installation, we had to buy new equipment. With the prepolish-type connector, you need that type of kit to crimp it. Terminating an SC connector with epoxy doesn`t require a lot more material--just a polishing puck."

An SC connector may require different tooling, but you will probably not have to buy a new fully equipped kit. Silver explains: "A fiber-optic installation kit is going to cost $900 to $1200 and, to install the SC connector, you may have to buy an additional $100 worth of components--a new polishing puck, crimp tool and, for the hot-melt connector, there`s a different holder."

Connector technology

Since the first fiber-optic connector, manufacturers have been improving the technology to reduce installation time and make it easier to install. The first connectors used epoxy, which is still in use, and then hot-melt connectors reduced installation time to approximately 5 minutes. Next came no-adhesive connectors, where the fiber is gripped with a mechanical device, followed by anaerobic adhesive connectors, which do not require an oven, and UV-curing (quick-curing) and crimp-style connectors.

According to manufacturers, the crimp-style SC connector reduces the termination time and minimizes the need for associated products. "You don`t need an oven or power supply," says Sappe. "You don`t have to cure it and you don`t have to polish off the epoxy--there is none."

Installed Base of ST Connectors

End users and contractors who have an installed system with ST connectors will have to decide how best to handle the Telecommunications Industry Association`s recommendation for SC connectors in new installations. If you are adding to an existing system equipped with ST connectors, however, you should continue to use ST connectors to ensure system-wide compatibility.

"We have all ST connectors," says Jerry Thornton, assistant manager, Network Services, University of Vermont (Burlington, VT). "As the industry moves over to the SC, we will probably have to change over. The tough part is that all our equipment for making connectors is for the ST, so we won`t change until we absolutely have to."

Users with an installed base of ST connectors who want to retrofit the site can use ST/SC hybrid adapters, instead of cutting off the existing ST connectors and reterminating the fiber with SC connectors. However, these hybrid adapters are not recommended in new installations, because then you would have to maintain and troubleshoot both types of connectors. [For more information on hybrid adapters, see April 1995]

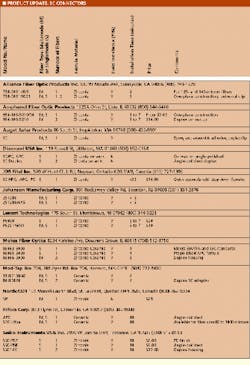

An SC connector (bottom, shown with adapters) can be duplexed for singlemode (blue) and multimode (beige) fiber-optic systems.