When it comes to bringing systems back up after an outage, hope for the best but plan for the worst.

Scott Bowman, Liebert Global Services

If your plant loses power, it is critical to have a plan in place that will enable you to bring it back online. Planning for a power outage is critical because planning, coupled with training, will minimize the effects of such an outage and, more important, get you back in business faster.

All plant personnel responsible for restoring power to the facility must know what to do in the event of an outage or other failure. Obvious dangers exist if only the plant manager knows the recovery plan. If the plant manager is away from the facility, staff members who do not know the plan will be left scrambling for information. Furthermore, power disruptions can occur at any time--not just during working hours.

Working with a specialist before an outage can ensure that your power-protection strategy fits your needs. Such specialists are an industrial systems integrator or reputable uninterruptible power supply (ups) vendor. The industrial systems integrator can provide a detailed plan of how to respond to a power outage.

Creating a series of written instructions on how to restore power is essential to a successful recovery plan. It is also important to keep documentation of all service calls and of any changes made to your power-distribution systems. (These procedures are good advice for any business, not just industrial plants.)

The plan should also pinpoint power sources for all equipment and include accurate documentation of any changes affecting this equipment. Determine the order in which the equipment will be repowered, noting the sources of that power. Make sure all responsible personnel are aware not just of the plan`s existence, but also of its details.

Restoring power

When you have a power outage, the team assigned to handle power restoration is first assembled and readied to implement the plan. The first devices to be restored should be life-safety items, including lights, fire protection, security, and other emergency-related equipment. Next, critical pieces of plant equipment should be brought back online. Then secondary machine equipment should be brought up. Included among the last group to have power restored are non-critical office space, break-room equipment (such as microwaves, refrigerators, and vending machines), and basic work cubicles. Generally, office personnel can wait until the plant equipment has been restored. However, each situation is unique.

Multiple transfer switches are used to bring up each of these groups of equipment in a predetermined order specific to your situation. The process of repowering the plant is different for every site. Your plan`s specifics will depend on your facility`s needs and on the order in which personnel will be needed back online.

Devising a recovery plan, and informing staff members of that plan, are the most important steps plant personnel can take to prepare for an outage. Downtime and resultant losses will be minimized if a well-thought-out plan is developed and implemented.

Sizing power protection

Sizing a ups to your plant`s equipment is no different than sizing one to any other piece of sensitive electronic equipment. Basic rules apply to the sizing of all upss. First, the maximum (not nominal) load the ups will have to protect must be determined. Second, the amount of battery-backup time needed must be established. Industrial equipment does not necessarily need a larger or heavy-duty ups, but the ups must be able to handle the in-rush of the equipment to be protected. Sizing the ups and its battery-backup capability are different for each plant.

One common misconception among industry users of power is the assumption that a factory power system has some inherent ride-through capability not present in office environments. This is not true. ups manufacturers recommend an analysis of power conditions at a site before purchasing power-protection equipment. This analysis allows consumers to determine accurately the level of power problems that exists and likely internal causes that can be isolated.

Power protection involves unique challenges for the plant engineer and industrial facilities manager. Adequate power protection in a plant setting is necessary because process-control equipment is just as prone to power- related shutdowns as are data-processing computers. A control system`s microprocessor is just as sensitive as one in an office computer.

The poor and inconsistent power quality of incoming utility lines has been well documented, and process-control electronics are very sensitive to power sags, surges, and even millisecond-long power interruptions. Many users think of outages only in terms of several minutes or hours, but that`s not the case. Interruptions occur much more frequently, yet most are so brief that people are unaware of them.

Special designs and considerations

While the electrical-system design for a ups is similar in an office and in a factory, additional factors may be found in an industrial setting. One such factor is that corner-grounded or ungrounded delta utility configurations are commonly found in older manufacturing environments. These configurations are outside the standard wye configuration typically used in commercial-building design.

Delta utility configurations can create grounding, isolation, noise and operational problems if the ups is not designed to anticipate them. For instance, such a plant configuration could cause the ups to sense that the utility feed has moved out of range, so that it begins to draw down its batteries.

Although office and industrial environments are both vulnerable, they are not identical, and at times can require differing design considerations for electrical and support systems. However, these differences do not always require ups equipment to be designed differently. At Liebert, for instance, we recommend a variety of topologies, and we base those recommendations not on the application, but on the power range required. For example, certain topologies are more effective at lower kilovolt-ampere ranges, and others are best for larger needs.

The plant environment is likely to create internal power surges and sags, as electric motors and other heavy equipment place momentary draws or surges through a facility`s power system. In addition, some processes in a factory are just as critical as data-center processes; rollers, for instance, or other load processes may not be stopped for even a moment.

An alloy manufacturer, to take one example, may use a process that takes 21 days to produce the final product. This manufacturer cannot afford any power interruption. If one were to occur, the manufacturer would have to restart the lengthy production process. For this company, proper sizing of the ups and its battery load is critical.

Power conditioner or UPS?

When considering solutions to power-protection problems, the first question usually centers around determining what level of power protection is needed--a power conditioner or a UPS.

A beneficial first step is to determine the difference between the two. Appropriately used, a power conditioner is a device that regulates, filters, and provides isolation. An online ups provides all the features of a power conditioner, as well as battery backup in the event of a power interruption--whether that interruption is milliseconds or several minutes in duration.

When should one technology be used over the other in industrial applications? The answer is application-driven and consequence-oriented. If a power outage of any length would lead to downtime or crashes of a system critical to operation, a ups is required. Power-conditioning systems are appropriate at sites that are not prone to outages or disruptions, and that can survive an outage with minimal or no damage to processes or equipment.

The conditioner-or-ups decision also has to do with site location. Electric-utility grids in large cities with multiple utility feeds are reliable, and often a power conditioner without battery backup is sufficient. However, if your industrial site is at the end of an electrical distribution line in a remote area, your exposure--and therefore your need for protection--is greater.

Another industrial ups design consideration involves unusually long distribution runs. In a manufacturing setting protected by centralized ups systems, the ups can be at one end, while loads are as far away as 200 feet or more. In this case, you must account for voltage drop and cabling size issues. You may have also introduced other uncertainties. Long cables can be cut or damaged, and noise is more easily introduced to the line with long cables than with shorter ones.

Today, the distinction between upss and power conditioners is blurring. Many upss now offer both constant, online power conditioning and battery backup combined into one unit. Also, the gap in price between upss and power conditioners has narrowed, making the ups a more cost-effective choice than before.

The ups is part of a complete facility. As such, it should be a consideration when you are purchasing other equipment. Integration issues should be based on a growth plan for the power-protection unit as well as the facility in general. Increases in power capacity must be considered when purchasing any type of power-protection or conditioning equipment.

Will a large, central ups be needed, or will several smaller units suffice? How much battery time is required? (A given station, for example, could need a particular number of minutes to finish a batch process.) When is it more practical to continue to purchase additional battery cabinets, and when is it more economical to install a diesel generator in conjunction with a ups for extended outages?

Finally, what communications and local area network equipment is being installed in the facility, and what connectivity to other computer systems is needed? As companies seek to collect and integrate statistical process information, connectivity issues become critical, even for power-monitoring options.

Bill Walker works with an online ups in the equipment room of West Ark Community College in Fort Smith, AR.

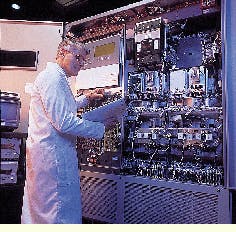

The Liebert Series 600T online ups provides the features of a power conditioner, as well as battery backup in the event of a power interruption, regardless of the interruption`s duration.

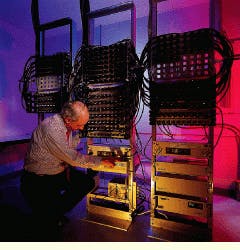

Proper sizing of the ups and its battery load is critical for organizations that cannot afford any type of power interruption. In this photo, an engineer adjusts a UPS.

Scott Bowman is Midwest region manager for Liebert Global Services (Columbus, OH), a manufacturer of power-protection products.