Manufacturers, designers, end users, and contractors are all playing their roles in the green phenomenon.

The "green" phenomenon that appears to be overtaking the cabling industry and many others is starting to change the way companies do business. Manufacturers are implementing more environmentally friendly processes; product development teams are designing greener products; designers are striving for energy efficiency in the data center; and property owners are building LEED-certified facilities.

As infrastructures for these greener data centers and facilities are deployed, cable installers can also play apart in the stewardship of natural resources by putting better workmanship practices into place.

Lean green manufacturing

When you consider the market supply chain,cabling infrastructure solutions start at the manufacturing level where environmentally friendly practiceshave a significant impact. Lean manufacturing, a principle derived from Japanese industries, isan optimal way of producing goodsthrough the removal of waste and implementation of efficient workflows.

Lean is based on a set of tools and processes that identify and eliminate waste, with the ultimate goal of improving quality and reducing production time and cost. Most leading manufacturers in thecabling industry already implement lean processes, and have been doing so for many years. Now, the focus on going green has intensified lean manufacturing initiatives more than ever.

"With lean manufacturing, Panduit was green before it was even called green, but there's no question that the mindset is changing across the industry," says Mark Acklin, group vice president for Panduit (www.panduit.com). "When we look at new manufacturing equipment today, we're looking for solutions that use dramatically lessenergy. Right now, with the cost of energy, economicshas become a major driver of the green phenomenon."

Energy consumption and costs are on everyone's mind, and while lean processes strive to reduce wasted energy in the manufacturing environment, that same principle is now hitting the streets. "When it comes to transporting goods into the market, we're looking to follow the most efficient routes and consolidate freight as much as possible—not just to distributors but to our own global warehouses as well," says Acklin.

Another angle of green in manufacturing doesn't have as much to do with energy-cost reduction as it doeswith simply being a good global citizen. Fueled by regulations like the 2006 European Union's Restriction of Hazardous Substances (RoHS) directive, industry manufacturers are now striving to eliminate the useof hazardous substances and dramatically reduce the amount of raw materials.

"Today, all of ADC's telecommunications cables are lead-free and RoHS-compliant," saysDavid Yanish, director of marketing programs for ADC (www.adc.com). "We recyclewherever possible, and we implement processes to avoid emitting any hazardous substance into the environment."

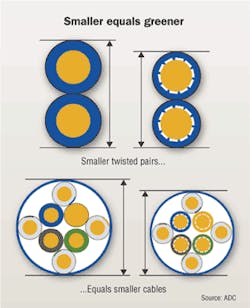

Yanish points out that the smaller diameter of ADC's AirES cable doesn't just improve airflow in the datacenter: "There's a tremendous raw-materials savings with smaller-diameter cable, and we've calculated a savings of1.25 pounds of copper and nearly 1.5 pounds of FEP [fluori-nated ethylene propylene] per every 1,000 feet of Category 6cable we manufacture. When you consider a cabling job that requires one million feet of cable, the impact is far greater."

ADC has posted a green calculator on its Web site so customers can see how much copper and FEP is being saved for a specific project.

Building better products

With reports stating that data center energy use surpassed that of all U.S. color televisions in 2006, it's no wonder that much of the green initiative is focused on data centers. From a product-development standpoint, that means more than just eliminating hazardous materials. Active equipment vendors are busy reducing the power consumption of their products to meet new Energy Star requirements while cabling-infrastructure manufacturers develop new products to help improve management and airflow in the data center.

"We can look to Energy Star as the first step in trying to bring down the amount of heat generated by servers and switches and, consequently, the amount of energy used by CRAC [computer room air conditioning] units in the data center," says Andrew Fanara, leader of the EPA's Energy Star product development team (www.energystar.gov). "However, data centers need to be looked at as a whole, and implementing efficiency and best practices goesa long way in reducing energy consumption."

ADC's Yanish couldn't agree more: "The benefit of proper cable management in the data center is a huge part of reducing energy consumption. Using products that help improve airflow are simple measures that can be made without a huge capital investment."

Like many others in the industry, Panduit's product-development team is concentrating heavily on improving airflow in the data center. "In all of our cabinet, rack, and cable-management system designs, our guiding principle is to improve active-equipment efficiency by conserving cool airand improving airflow," says Mike McGrath, product linemanager. "By designing solutions that manage cables away from equipment inlet and exhaust areas, and minimizingcable slack buildup, we can actually facilitate energy savings.It's a win-win; the equipment runs cooler for a longerlifespan, and fans don't have to use as much energy to maintain the correct operating temperature."

Panduit's approach has led to products like cabinets that passively channel out hot air, liquid-cooled doors that decrease exhaust temperatures, and a raised-floor air-sealing grommet that conserves cool air by sealing cable entry points. "We believe that a passive approach is preferred, because adding components like cooling fans increases energy consumption and capital costs, and adds reliability issues," says McGrath.

LEEDing the pack

But it's customer demand that is theunderlying reason for efficientdata center products. Most in-dustry manufacturers are seeing that demand primarily come from end users and designers. End users are striving to reduce energy bills and become better citizens by building LEED (Leadership in Energy and Environmental Design)-certified facilities under the U.S. Green Building Council (USGBC). Consequently, data center designers are demanding more energy-efficient strategies and solutions.

"Designers and consultants are paying close attention to green initiatives, and they're looking for products that can help them design green data centers to differentiate their business," says ADC's Yanish. "As a result, we developed a green ordering guide tohelp customers determine which products can be used todesign a more energy-efficient data center." The green datacenter ordering guide includes strategies and productinformation for managing airflow in thedata center and for selecting greener cable.

Many new construction projects are striving for LEED certification. To date, LEED has primarily covered material selection, site sustainability, indoor airquality, and water savings for commercial buildings, but not data centers. Hence, it's been difficult for data centers to achieve LEED certification unless they are part of a mixed-use facility.

"We've seen LEED-certified facilities that included some of the most inefficient data centers," says Yanish. "They essentially acquired certification based on criteria such as the use of naturallighting, waste-water management, or the amount ofrecycled construction materials. It's our hope the USGBCwill soon develop LEED certification criteria for data centers based on upcoming energy-efficiency metrics."

Organizations like The Green Grid (www.thegreengrid.org), a global consortium dedicated to advancing energyefficiency in data centers, are developing data center metrics forthe USGBC to set criteria for LEED data center certification. Once those criteria are in place, it's anticipated that the demand for greener products and practices will explode among endusers and designers.

Unexpected players

While cabling contractors have not been considered significant players in the green phenomenon, they can play a key role through greener workmanship practices and consequently differentiate themselves from the competition. Contractors can start by educating themselves about data center energy efficiency, and the products and practices thatimprove airflow while reducing power consumption.

"We're teaching installers how to install energy-efficient data centers by deploying practices like better cable management,installing blank panels in unused rack units to channel airflow, and taking the cabling out of the raised floor and placing it overhead," says Yanish.

Along with hotter electronics, data centers encompass higher cabling densities. By reserving the under-floor space for permanent power and grounding systems and moving telecommunications cabling overhead, the cooler air flowing from perforated floor tiles in the hot aisle/cold aisle configuration is not altered or blocked by network cabling.

Sometimes, implementing efficient products and prac-tices can cost more up front, causing some contractors toavoid going green. But if the long-term cost benefits andsustainability are properly explained during the bidding process, end users may appreciate a contractor who presents a greener installation. Contractors also have the choice to purchase lead-free or RoHS-compliant cables from greenindustry manufacturers, and they can consider simple prac-tices like reducing packaging and waste at the job site.

"Reducing the amount of packaging materials brought to the job site is a very green practice," says Panduit's McGrath. "Not only do pre-terminated solutions offer faster and easy data center deployments, but they also offer minimal onsitewaste. There is a 10 to 15% reduction in the amount ofscrapped cable by going with preterminated solutions."

Greg Bramham, vice president of Beast Cabling Systems (www.beastcablingsystems.com), points out that the use of larger cable reels also has a significant impact on reducing the amount of packaging materials that require disposal: "Boxes of cable involve a lot of waste, including the box itself and the plastic components. Larger reels reduce that waste dramatically, and the reels themselves are typically wooden and recyclable."

Bramham points out that larger cable reels also result in much less cable scrapped during installation: "Most cabling crews will waste about 100 feet of cable per spool, regardless of the size of the spool. Therefore, a crew using ten 1,000-foot spools will waste 1,000 feet of cable while crews using four 2,500-foot spools will only waste 400 feet."

He adds, "It's not just about deploying green installation strategies on the job. Installers can look at their own internal operations as well. They can plan properly and use more-efficient installation methods to get the job done faster and avoid making extra trips to the job site. They can reduce fuel use by consolidating crews into fewer vehicles and opting for morefuel-efficient vehicles whenever possible. They can simply turn off the lights and implement their own recycling initiatives."

A never-ending initiative

While manufacturers, designers, end users, and installation contractors all play a role in making the industry greener, not everyone is on board. And even those that are going green still have work to do.

"It's a lot harder to catch up than to have the mindset to start with," says Panduit's Acklin. "From a manufacturing standpoint, it's about continuous improvement, knockingout waste, and following the highest global regulations and customer standards available. If you point yourself in thatdirection, you're going where you need to go."

He concludes, "If you get your waste, hazardous materials, and energy consumption down to the lowest levels, it doesn't just stop. We need to keep coming back to these things andpursuing them over and over again. At the end of the day,green is good business."

BETSY ZIOBRON is a freelance writer and regular contributor to Cabling Installation & Maintenance. She can be reached at: [email protected]