Producing increased cooling while reducing cooling costs—two computer room management objectives—are widely held to be mutually exclusive. But by applying basic thermal management concepts, which sometimes contradict conventional wisdom, these objectives can be met simultaneously.

Temperature affects IT hardware in an assortment of ways. Often, seemingly inconsequential changes have significant performance and economic impacts. A good rule of thumb is that every 10 degrees (centigrade) increase in ambient temperature produces a 50% reduction in long-term reliability of IT hardware.

Temperature also affects clock speed. For a 1,500 MHz CPU, every 10 degrees centigrade temperature reduction results in a 2% increase in clock speed. While 2% may not seem exceptionally significant, in a large data center dedicated to processing a high volume of transactions with two rack-mount unit (RMU) servers, losing that extra 2% of transaction turnover means having to buy and install an otherwise unnecessary server every two and-a-half racks.

With this knowledge, exuberant computer room managers must guard against simply adding more computer room air conditioning units or cranking down the thermostat. Proper air management depends on a basic understanding of how the principles of forced air convection heat transfer rates cool equipment.

Conventional approaches have focused on getting the heat out of the cabinet and focusing cooling efforts on hot spots. The principles of forced air convection heat transfer, however, clearly indicate that the benefit to CPU performance and life results from the delivery of the coldest available air directly to the conductive surface area attached to the microprocessor. Managing air movement is quite simply a matter of putting the air to work where it is needed most.

The best course of action is to manage air movement under the floor tiles as well as the way cooled air is delivered to equipment. Using this strategy, computer room managers can often raise thermostat temperatures and remove computer room air conditioning units from service while improving cooling.

Managing air movement

The first step is to reduce bypass air—air that is escaping from under the floor—and increase static pressure. Sealing off all the escape points for bypass air increases the static pressure under the raised floor, increasing the air flow (cubic feet per minute, or CFM) at the points of need.

Most computer rooms allow 50 to 80% bypass air resulting in static pressure under the raised floor of approximately 0.01" of water, which will deliver around 200 cubic feet of air per minute through a 25% open perforated floor tile—inadequate cooling for a normally loaded cabinet. Blocking off enough of the bypass air to raise that static pressure 0.09" will more than triple CFM delivered through a floor tile and quadruple the cooling delivered to a cabinet.

Three primary sources of bypass air must be closed through operator diligence or by sealing with standard plenum-rated foam, fabric or other pliable material:

- Open doors and access points into the room under the raised floor for cable, power and plumbing;

- Removed floor tiles;

- Misplaced floor tile openings designed to add to computer room staff comfort, or cable access into the cabinet.

Second, do not position computer room air conditioning units at right angles to each other. Air streams from these units do not mix, so if they are located at right angles to each other, the cooled air output patterns are diverted in angles that cannot be predicted by return air patterns in the computer room above the floor.

Next, you should deploy a "hot aisle-cold aisle" setup. The best approach to making air direction both below and above the floor predictable is to ensure that all the air and cable run in the same parallel direction. This also creates some redundancy for protection against computer room air conditioning unit failures or service downtime, and removes cable obstruction as a source of turbulence, reduced static pressure and lost CFM.

Avoid the typical tendency to locate the hottest equipment closest to the computer room air conditioning unit. The air velocity from the unit may be too high to be diverted up through a perforated floor tile located too close to the unit. Not only will that fail to deliver cooling to the hottest equipment, but it may raise the temperature of the chilled air delivered into the entire room. Where possible, locate passive, connectivity equipment closest to the unit to maximize use of space.

If the bypass air elimination produces adequate CFM through all the perforated floor tiles, the cabinet should either have no doors or, if required for security, doors with a minimum 60% open mesh for maximum airflow, with no top-mounted fan kits. Top-mounted fan kits can be counterproductive and allow return air and source air in the cold aisle to mix. Any temperature increase will produce a commensurate decrease in the heat transfer rate within the mounted equipment.

If cabling obstacles in the rear of the cabinet make it difficult for the small server fans (10-30 CFM) to push the hot air out of the cabinet, use rear door-mounted fans to push air directly into the hot aisle. Keep the cabinet between the source air and the return air.

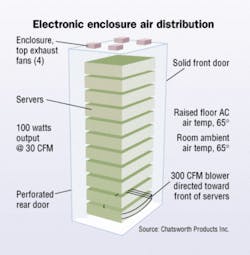

When the optimal CFM cannot be maintained, air must be pumped directly into the cabinet and distributed with a booster. Static pressure is increased by installing a solid panel front door, filler panels in unused RMU spaces between equipment, and sealant between the equipment and the cabinet side panels. When cabinets are bayed together, two cabinets should share a side panel.

Top-mounted fans may be deployed in this configuration because their output will not mix with the equipment input air. The "boost" is provided by mechanisms that focus the coldest air directly on the most critical point of use. This could be, for example, centrifugal blowers, which direct the chilled under-floor air through a nozzle up the front of the equipment; or fans, which direct the air into a "plenum" door with vents or baffles that will direct it into the cabinet to points of need.

In other words, deliver effective cooling; don't merely get rid of hot air. Resist the temptation to turn down the temperature and add more cooling units.

Ian Seaton, marketing manager for Chatsworth Products, Inc., is responsible for the CPI Delphi Enclosure Blower product line. He can be reached at: [email protected]