Using approved firestop methods and materials, such as special caulk, putty, wrap strips or fire-barrier sheets, can reduce risks to structures and their occupants.

William Carnel, 3M Fire Protection Products

Sealing or firestopping openings where cables penetrate fire-rated walls and floors is an important aspect of cable installation and maintenance. When fire erupts in a building, small openings in fire-rated walls, floors and ceilings for wires, pipes, ductwork and other building components become open channels for fire and toxic smoke, endangering both a structure and its occupants.

In telecommunications facilities, even a small amount of smoke can cause catastrophic failure of delicate switching equipment or computer systems. Firestopping is essential to ensure continuity of operations.

Statistics confirm that smoke inhalation is the predominant cause of death in fires of all sizes, and by compartmentalizing a building with fire-rated enclosures sealed against escaping flame, smoke and gases, it is possible to significantly reduce the chance of injury or death. Insurance companies, architects, building owners, contractors and local enforcement jurisdictions are all interested in safety issues. Cabling contractors also have a personal interest in firestopping because improper work will result in rejection by inspectors, necessitating costly rework.

Fire codes in virtually all municipalities now require that fire walls and floors in commercial buildings be firestopped to preserve compartmentalization and contain a fire within the area in which it started. Codes from organizations such as the International Conference of Building Officials, the Southern Building Code Congress International, and the Building Officials and Code Administrators International Inc. cover firestopping materials and methods, which require that every wall and ceiling penetration be sealed. Wire and fiber-optic cabling for telephone systems, computers, hvac systems and other electrical or electronic signals are an important part of the firestopping process.

Makeshift sealing of penetrations with drywall cement, construction caulk or other materials is not satisfactory because these materials cannot provide the required protection. A firestop must not only stop the spread of flame and heat generated in a fire, but it must also restrict smoke and toxic combustion products, as well as water from fire-fighting activities and leaky plumbing.

The approved firestop methods required by building codes pertain to materials and devices that form systems that have been tested independently in accordance with a nationally recognized test standard. Products that meet testing standards are then listed by the laboratory as effective in the application for which they were evaluated.

Fire protection testing is severe and simulates conditions encountered during an actual fire. In 1983, the American Society for Test Methods (astm) developed astm E 814, which contains rigorous firestop testing standards. In this test, one side of a firestopped barrier penetration is exposed to temperatures as high as 2000F (1100C) over a 4-hour period, and penetrations must remain closed during that period. While still glowing hot, the surface of the firestopped wall or floor assembly, including penetrations and firestop materials, is bombarded with water as cold as 50F (10C) at a pressure up to 45 psi, for three seconds per square foot of test area. This reveals whether the firestop can withstand the impact, erosion and cooling effects of the hose stream. Firestops that survive this particular test sequence qualify for a 4-hour rating per the astm standard.

There are many different types of fire barrier penetrations, and the current Underwriters Laboratory (UL) listing of firestop applications includes more than 600 specific situations. Many of these call for combining two or more products as components of an approved system for a specific application. Firestop materials to be used together must be tested with one another and be compatible under all conditions.

Most firestop systems involve three basic properties, which are used in different combinations. The first property is intumescence, which describes materials that swell and enlarge when exposed to heat. 3M has used this intumescent technology in the development of a series of fire protection caulks, putties, wrap strips and sheets. When exposed to the heat of a fire, these materials will expand as much as 10 times in volume to form a high-strength, insulating and fire-resistant char.

Intumescent materials expand in proportion to surrounding temperature, beginning at approximately 250F (121C), and reaching full expansion at about 1000F (540C). The high strength of the resulting char is as important as the intumescent action because it allows the seal to resist the thermal and dynamic shocks that occur during a fire, including those created by fire-fighting activities.

The second property involves endothermic reaction. Materials using this technology release chemically bound molecules of water under heat. As temperature increases, water is driven out of the material in the form of steam, which cools surrounding surfaces.

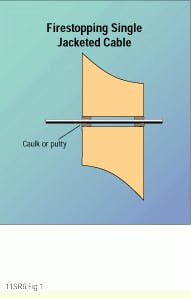

An example of a firestopping material that combines both intumescent and endothermic properties is synthetic elastomeric latex fire barrier caulk--a one-part firestop sealant that can applied with an ordinary caulking gun. A firestop caulk is used for permanent wire and cable installations where changes are not anticipated.

The third firestopping property is ablative. Such materials are typically silicone-based and help resist fire by slowly eroding and forming a char when exposed to high heat conditions. The elastomeric properties of the best UL-listed silicone-based firestop sealants and foams make them useful for filling construction joints and gaps, accommodating structural movement.

For hand application and locations where periodic cable changes are anticipated, moldable putties are used to fill penetration openings. Like caulks, such materials form a cold smoke and gas seal, and have both intumescent and endothermic properties. Putty is formed or molded to fit a cable opening and pressed into place.

A surprisingly small amount of intumescent caulk or moldable putty can provide high fire ratings. For example, a typical 2-hour penetration seal in concrete with 12% to 40% cable fill requires a 1-inch depth of mineral wool, and 1 inch of fire- barrier-rated putty. If it becomes necessary to add or subtract cable in a cable penetration, firestop putty is easy to remove and reuse. Multiple cables can be packed together with putty throughout the bundle and around its circumference to complete a firestop.

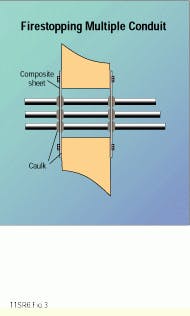

For larger penetrations, such as multiple conduits or conduit/wire/pipe combinations through a wall or floor opening, a special fire barrier sheet is used. Known as composite sheet, such a panel consists of a metal mesh-reinforced layer of intumescent material bonded to sheet steel. Composite sheets can be used to cover simple square or rectangular openings, or cut to match the contour of irregular objects. The purpose is to close very large openings around penetrating cables or other elements. Composite sheets are secured to a wall, floor or ceiling with metal fasteners and sealed around their edges with firestop putty or caulk. Individual penetrations through the panel are also sealed with putty or caulk.

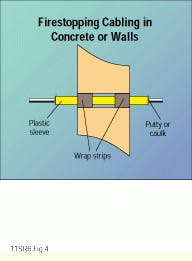

Plastic sleeves used to protect cables passing through a wall or floor can be firestopped with a flexible wrap strip material that is wrapped around the penetrating sleeve. This strip is intumescent and will expand to fill the gap resulting from a burned or melted plastic pipe. If sleeves fit the penetration too snugly to allow room for wrap strips, a one-piece metal collar that combines moldable putty and intumescent wrap strip is wrapped around the pipe and secured to the wall or floor.

Cable installers can minimize both labor and material cost related to firestopping by keeping cable openings as small as possible. Large penetrations require excessive firestop material and may create the need for structural work. Innerduct should be fire-rated, and cables passing through an innerduct need to be plenum-rated.

Firestopping is a passive complement to active systems such as sprinklers and fire alarms. Should fire break out, proper firestopping will prove to be a decisive factor in protecting life and minimizing property loss. Training and application-specific solutions are critical to successfully install fire-protection products and to satisfy fire codes. Such support is available to the cabling industry through some fire-protection suppliers and their distributors.

An innerduct is prepared for insertion in a floor opening with a section of 3M FireBarrier Wrap Strip. This strip will expand in the event of fire to fill any opening created by burned or melted duct.

Moldable putty is used to fill penetration openings in locations where periodic cable changes are anticipated. The putty can be used for single jacketed cable passing through concrete, block or gypsum.

Mineral wool and fire-barrier-rated putty used to firestop multiple jacketed cables running through concrete flooring can provide high fire ratings.

Multiple conduit running through a large concrete or block-wall opening needs a composite sheet and caulk for proper firestopping.

Plastic sleeves that are used to protect cables passing through a wall or floor can be firestopped with a flexible wrap strip that expands under heat.

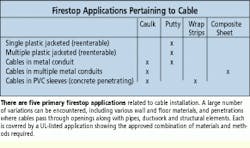

There are five primary firestop applications related to cable installation. A large number of variations can be encountered, including various wall and floor materials, and penetrations where cables pass through openings along with pipes, ductwork and structural elements. Each is covered by a UL-listed application showing the approved combination of materials and methods required.

William Carnel has 10 years` experience in commercial fire protection, training and market development at 3M Fire Protection Products in St. Paul, MN.