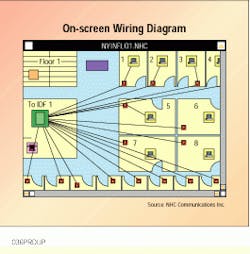

The Wireman cable management software screen shot depicts network connections from the intermediate distribution frame to each wallplate.

Barbara E. Thompson

Cable management software, or CMS, is a graphical application that can be used on a personal computer to manage your campus-wide cabling system supporting voice, data and video. Also available is a more-advanced CMS technology that combines hardware--an "intelligent" crossconnect switch located in the wiring closet--and the applications software to control the system from a PC. The PC is connected to the switch by an RS-232 cable, a dedicated line or through the network.

"From a management perspective of the physical layer," says Sidney Bouzaglo, senior product manager at Northern Telecom, "this technology is the beginning of a new era where you put some intelligence into the way the physical layer is managed."

If the CMS is a computer-aided design-based package, the physical design, routing and location of cables and devices can be identified and managed from the PC. In addition, the information in the database assists the user in managing moves, adds and changes, issuing work orders, and controlling inventory. Using computer maps, floor plans and an accurate database of all the wiring components in the network, system designers, installers and network managers can design, document, reconfigure, expand and maintain the cabling infrastructure--whether copper, fiber or coaxial system.

Physical design and connectivity

As a system designer, for example, you can use CMS to develop a physical map for a new or expanded installation, showing telecommunications closets, horizontal and vertical cabling paths, and user connections. The configuration data might include main and intermediate distribution frames and patch panels, and termination points such as ports and jacks.

"We use CMS for designing systems and it saves a lot of money," says Amy Barnes Frey, president of Alpine Communications Consultants Inc. (Broomfield, CO). "If the system is designed appropriately, it will automatically update your drawings and documentation so you only have to make one change. You don`t have to update your drawing and then update your database."

The CMS includes a database of standard components, including cables, patch panels, connecting blocks and patch cords. The software will also allow you to define any specific components for the project and add them to the database. Some databases are multimedia, where you can attach photographs or scanned images to a graphical element, and data from handheld testers.

According to Barnes, there are three ways to build your database:

- Each time you make a change to the system, you document it.

- Do a physical audit and detail everything you can in the database, and allow your database to change as work orders come in.

-Do a combination of both, including any available background information.

Maintaining an accurate database is critical to designing, managing and troubleshooting your campus-wide cabling network. Once you have a physical map, you can make changes and modifications easily on the PC, rather than making notations or redrawing floor plans. After the design has been approved, you can generate the appropriate schematics and a bill of materials for bid.

"When you design your cabling plant," says Bruno Paulet, president of Apsylog, "you build your documentation as you build your system. The requisition you send to your cabling installers is the first version of the system documentation."

The system designer and project manager work with graphic information such as floor plans, however, the field technician needs more-detailed information; for example, what type of connection to install in the telecommunications closet--IDC blocks or patch panels; what type of cable and where the cabling drops are; and the number and type of outlets and jacks.

Update the database

Most CMS packages offer an installation management and change documentation module for the installation phase of the project. During installation, if problems arise and you need to make different connections, delays can occur. By updating the CMS database as these changes occur, you can constantly review the floor plans while the work continues. As each phase of the installation is completed, you update the database and generate change documentation. At the same time, the software updates the inventory of materials, so you can control costs more closely.

End users usually require documentation at the end of a project, and you can generate this documentation from the PC. In addition, as specified in the Telecommunications Industry Association/Electronic Industries Association standard 606, installers should label cables and devices. Some versions of CMS will allow you to input information directly from the database to cable-labeling software and generate labels as the project proceeds. If updated throughout the project, the CMS database can save time at project completion by providing accurate documentation.

Once the project is finished and certified, the business of maintaining the cabling system usually falls to the network manager or system administrator. According to Kevin Considine, vice president at Cablesoft (Arlington Heights, IL), "The needs of the installer and end user differ. The contractor is concerned with putting the information into the CMS system and leaving it with the customer. On the other hand, the customer or end user is concerned about getting information out of the system and how to use the software to help make decisions about the network."

Moves, adds and changes

Network managers or installers can also use CMS to manage moves, adds and changes to the network. In fact, with some software modules, you can determine the appropriate connections to make, generate the work order and, when the work is completed, you update the configuration at the PC.

To do this, you first select the end points to be connected. By considering route, run, length and cable-fill status, the software will then search the database for the most-effective connection. Afterward, a recommendation will be displayed on the screen. You can also request an alternate route.

"You can also set specific conditions," says Paulet. "If you want to create a data connection between points A and B, and you want to build a Category 5 connection, you indicate that you want to use Category 5 components."

Once you accept the option, you generate a work order with all the relevant details. For copper cable, the specifics of the connection might include number, gauge and type of wire pairs; for example, 24-AWG Category 5 unshielded twisted-pair cable, and the port and jack. When the work is complete, you input that information, and the CMS updates the physical design of the network.

According to Bouzaglo, "The main difference between Dynatrax (crossconnect system) and current cable management software is that, rather than producing work orders and having a technician do the work, you execute changes from the computer screen, and the crossconnect switch makes the necessary changes in the telecommunications closet. Also, when making moves, you can move the patch cords on the screen (much like you do in the closet today) or you can just identify the end stations to be changed, and the system will do the routing."

The up-front cost of a CMS software package ranges from $250 to more than $50,000, depending on the number of modules and the level of technology. With the crossconnect-switch type of CMS, the cost is $125 to $210 per port. If the system is large, you may also have to consider the cost of human resources to input the data and maintain the database. The "intelligent" crossconnect may be cost-effective, however, for remote locations with no full-time technician.

The cost of your CMS may increase as you add specialized modules. For example, CAD interface links graphic information with nongraphic data, enabling users to view the network on screen or print illustrations of cable layouts and a description of the network; trouble-management module logs service calls, actions and solutions by building, department, part number, user or other variables, to help system managers identify trouble spots; cost allocation and directory management generates reports for budgeting and user lists.

The Wireman cable management software screen shot depicts network connections from the intermediate distribution frame to each wallplate.