The driving forces behind the success of this cable upgrade project were innovative cable design, system certification, and accurate documentation.

Ray Strano, MicroAge

With new technology changing so rapidly, organizations are rushing to upgrade networks to provide instant information and solutions to end-users. This consistent increase in demand for upgrades requires cabling contractors to respond quickly--with little room for error. Without proper planning, however, the push for a quick-fix upgrade could result in a compromise in quality.

Managers of information systems (MIS managers) are giving increased attention to the design and installation of cabling in system upgrades and new construction projects. In any upgrade, however, it is critical to view the network cabling strategy as an integral part of the larger system architecture. And this should be done in the early stages of the project to ensure that the network can handle future high-speed applications.

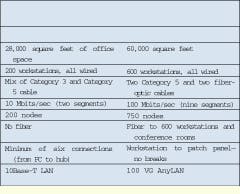

Similar installation upgrade projects can be developed differently, as the following case studies illustrate.

Planning the cabling

Jacobs Engineering Group Inc. in Pasadena, CA, is the third-largest engineering firm in the country, with more than 35 regional and 5 international offices. The northern regional office in suburban Philadelphia has just undergone a major expansion. The offices moved from an old elementary school building (converted to office space in 1975) to a newly constructed, three- story office building. Jacobs`s main service is computer-aided design and computer-aided engineering, both of which require heavy graphics use. A high-speed network, therefore, was one of the most critical issues in the upgrade plan for the move to the new building.

Brian Bartholomew, Jacobs`s MIS manager for the northern region, says that this substantial system upgrade, starting with the cabling, will dramatically increase productivity throughout the company and prepare Jacobs to move to future high-speed applications.

"Years ago, we ran into problems with an upgrade at another office site," says Bartholomew. "We spent a significant amount on wiring and just a few years later had to rewire to meet the company`s changing needs. At that point, we realized that, with the constantly evolving telecommunications technology, we needed to `future-proof` our other sites and client projects."

The main objective for Jacobs`s technical staff in planning the expanded Northeast office was to install two Category 5 lines at every desktop. MicroAge submitted a proposal that included the option of adding fiber-optic cabling to each workstation and, early in the development stage, Jacobs decided to run fiber to every outlet as well, at an incremental cost. Mohawk/CDT (Leominster, MA) and MicroAge devised a cabling solution to provide the headroom they predicted Jacobs would need beyond the next five years.

At almost the same time as the Jacobs`s project, MicroAge proposed--and later installed--a cabling solution similar to that of FPS, a suburban Philadelphia financial investment company. Although Jacobs and FPS are not in related businesses, their needs are comparable. The MIS managers from both companies wanted to build networks that would provide for future applications. "We decided to integrate fiber into our plan to meet new technology demands," explains Bartholomew. "Right now it`s dark, except for fiber being used for testing. But it`s there while ATM [Asynchronous Transfer Mode] moves us into the next generation of network applications."

By upgrading the cabling system with a customized solution from Mohawk/CDT, Jacobs should not have to continually recable the system, as it had done before.

"Because of the size of this upgrade," says Joe Duplaga, registered communications distribution designer (rcdd) and systems engineer at MicroAge, "we had to come up with innovative recommendations for this and the FPS project. Both MIS teams were determined to provide headroom for their respective projects. Jacobs plans to use the network and cabling plant as an example to clients of its ability to design a data communications network system that provides for many needs."

According to Bartholomew, this upgrade moves Jacobs Engineering to a new technological level. "At our previous location in the old school building, we could not cable for the types of systems we need in our business," he says. "It was a continual challenge to make moves, adds, and changes to an eight-year-old piecemeal system."

Occasionally, the MIS staff would have to drill through the floor to run a wire. It seemed as if they were creatively and continually retrofitting the existing cabling network. For the highly sophisticated, 24-hour functions performed by Jacobs`s engineers for its clients, it was critical to avoid downtime. As the company continued to grow, space also became an issue for the technical support staff, not only in the design to upgrade to expand the space for engineering and administration but also in their own department. (Before the move, three people and 12 servers shared one office space.)

Each outlet was upgraded from a mix of Category 3 and 5 cables to two Category 5 lines and two fiber strands. This mix was necessary because engineers at Jacobs work on project teams and need to move easily--with their computers--from one project site to another. The following upgrades were also made:

- From 10 megabits per second broken out into two 10-Mbit/sec segments (plus the wide area network) to 100 Mbits/sec with nine segments (plus the wide area network)

- New Integrated Services Digital Network capability

- Video teleconferencing capability to any desktop

- Change in protocol from 10Base-T to VGAnyLAN

The upgrade also minimizes connections to the hub. In the old network, there were at least six connections. The upgraded network uses direct cable connection from the patch panel to workstations.

Raceway system challenge

The Jacobs and FPS projects were designed using modular furniture with raceway systems. The cabling channel system brings power and cable to the desk level to facilitate moves, adds, and changes. Faceplates from AMP Inc. (Harrisburg, PA) were built into the furniture, providing easy access and an aesthetically pleasing look.

Although functional, space-sensitive, and designed to work with all cable types, the modular furniture presented a challenge in routing the many different media through the channels: two Category 5, two Category 3, and fiber, as well as standard power cables.

"This was quite a challenge for the installers," says David Goldcamp, telecommunications services manager at MicroAge. "Pulling five cables for each workstation meant we had to come up with customized solutions. In dressing and routing the cables, installers had to pay particular attention and care to ensure proper bend radius."

With this type of modular furniture, installers were focused on meeting the bend radius of fiber, which is 10 times its diameter, whereas unshielded twisted-pair cable allows a tighter bend radius of only four times its diameter.

"In both installations--Jacobs and FPS--bend radius was not the only issue," says Goldcamp. "In addition, we had to meet the required fill ratio and ensure that data cables were always the proper distance from the power source."

Most of the furniture workstations in the FPS installation were served from columns. The installers pulled the cable through the ceiling, down the column, and into the furniture raceway system. Because of the size of the cable bundles, ordinary conduit could not be used. Instead, MicroAge fabricated custom conduit for the cable run and termination.

At both sites, the horizontal cable was routed through a ceiling distribution system. At the Jacobs site, the cables were installed in a star topology from the main crossconnect on the second floor and the telecommunications closets on the first and third floors. In addition to the 600 workstations, contractors also wired six conference rooms in the building with five dual Category 5 plenum-rated cables for data, and five Category 3 plenum-rated cable for voice to provide training and videoconferencing. The cables were terminated on AMP Access Floor Workstation Modules (afwm) with five 3-port faceplates. Each jack was wired according to T568B wiring, and the cable installation was completed according to tia/eia-568a standards.

Cables were suspended from the building structure with J-hooks every four to five feet, in compliance with eia/tia-569. Installers used Velcro tie wraps in the main crossconnect to prevent undue strain on the cables or terminations that might affect system performance.

While the former Jacobs building presented ongoing obstacles for the MIS group maintaining and upgrading the system network, what they learned through eight years of constant troubleshooting has honed the group`s skills in planning and targeting for future needs.

"For the network and premise wiring integrator, knowledgeable hands-on end-users appreciate what goes into a large upgrade project," says Duplaga. "As in any business situation, if a client is involved in the preliminary stages of the project and makes the decision, there is a vested interest in making sure the project is a success."

According to Jacobs`s MIS manager, having the manufacturer`s 15-year warranty added to his comfort level with the structured cabling system. "A 15-year certification is not an industry standard," says Bartholomew, "but it is important for the extended life of the system."

Although both sites required a reliable documentation package, this was especially critical at the Jacobs installation. "We inherited a `jungle` of wires; therefore, it took a considerable amount of time to troubleshoot when a user was down," says Bartholomew. "Since there was no historical documentation, we had no clue as to what went where."

MicroAge provided documentation of everything that was installed and all test results at the completion of the upgrade project. The software package includes a cable management program that enables Jacobs to achieve rapid system recovery and plan for moves, adds, and changes; it also serves as a database for the entire infrastructure.

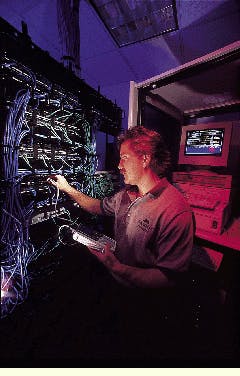

David Goldcamp, telecommunications services manager for MicroAge (Exton, PA) verifies cable for Category 5 compliance at FPS in Philadelphia.

In the ceiling distribution system, cables are suspended from the building structure with J-hooks every four to five feet.

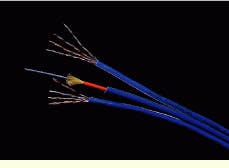

Customized cable from Mohawk/CDT (Leominster, MA) includes two Category 5 and one fiber cable.

Ray Strano, registered communications distribution designer (rcdd), is director of the network and premises wiring division at MicroAge (Exton, PA).