This universal wiring system serves today`s proprietary hardware but is also open to expansion and growth.

John B. McWalters, Words Inc.

Suffolk Construction (Boston, MA) broke ground in January 1994 for a $98.5 million high-tech center for the state of Massachusetts. In addition to general office space, the Massachusetts Information Technology Center, known as MITC, will eventually house 55,000 square feet of computer-room space for approximately 1200 users. The facility was designed with unique disaster-resistant design components and will function as a hub for extensive tax and data information, primarily for the state`s Department of Revenue and the Office of Management Information Systems. This mandates high quality-assurance levels, so the planners chose to install enhanced Category 5 cable for the building`s voice/data infrastructure.

In June 1995, Sullivan & McLaughlin Communications Group Inc. (Quincy, MA), the telecommunications cabling contractors, prepared to install the network in this 419,000-square-foot office building in downtown Chelsea, MA. The needs analysis survey, compiled by Shooshanian Engineering (Boston), focused on immediate and long-term needs of the agencies that would occupy the site. Peter Charland, a registered communications distribution designer and point man for Shooshanian`s design team, envisioned a cabling system that was "capable of handling present requirements, but designed with the future in mind."

In a review of the cabling specifications, the telecommunications contractors identified several potential problems, including the procurement of approximately 1.7 million feet of four-pair unshielded twisted-pair, or UTP, Category 5 plenum cable. (Because of a Teflon shortage, plenum cable was scarce and prices were high.) This amount of cable was needed to accommodate 9000 cable links extending over four floors.

Other questions regarding the safe moving, rigging and storage of the cable had to be answered early in the planning stages. For example, the plan included moving more than 100 spools of 25-pair UTP cable--each weighing more than 130 pounds--and storing the cable in traffic-free work areas where they were unlikely to suffer physical damage.

An estimated 10,000 man-hours were required to complete the cabling installation. With the size of the project and the number of subcontractors at the job site, the cabling company had to establish professional standards to maintain an orderly work flow. From the first day on the job site, installers documented and labeled all the wiring consistent with the Electronic Industries Association/Telecommunications Industry Association standard 606, to ensure that all future work on the communications lines could be easily and efficiently managed. Although many documentation tasks were streamlined by using computers, volumes of paperwork accumulated as the job evolved.

Because the work area was spread over four floors and covered nearly half a million square feet of space, crew members had to be kept continually informed for scheduling purposes. Tom Hazley, general foreman onsite, daily scheduled a crew of 8 to 14 workers to install, terminate, test and certify the network. In addition, Finley Mullally, project manager/estimator for Sullivan & McLaughlin, and Peter Charland of Shooshanian Engineering, who was in charge of the overall mechanical and electrical design of the MITC project, held weekly work-in-progress meetings.

The original cabling specifications subdivided the building`s four floors into four sections--1A, 1B, 1C and 1D--with each containing a telecommunications closet or intermediate distribution frame. Horizontal cabling was installed in aluminum cable runways below a raised floor, creating a horizontal pathway to open office areas. These cable trays, unique in a building of this size, were time-consuming to install, but the raised-access floors contributed toward the network`s open design for future growth.

Surprises and concerns

Much of the floor and some of the carpet had already been installed by the time the cabling crew arrived at the site. "This was the first of many surprises," says Hugh McLaughlin, principal at Sullivan & McLaughlin. "We were actually the second contractor called in--the first contractor had problems meeting all the job specifications. Work schedules, consequently, were slightly off, causing the flooring contractor to go ahead and drop in the access floor prior to the signing of our contract."

The crew had to remove sections of the floor panel to install the cable and then rebolt the flooring. Each floor panel, weighing approximately 60 lbs, was bolted at the corners and additional labor had to be hired to keep ahead of the UTP cable installation. "Our guys were under the gun most the time," says McLaughlin, "trying to execute 10 months` work in half the time."

In addition, the system blueprint specified approximately 9000 drops with more than 4000 faceplates. The horizontal cabling accommodates a star or home-run topology with four telecommunications closets on each floor. Risers run vertically from each of the intermediate distribution frames (16 closets throughout the building) served to link the closets to the main computer room or centrally located main distribution frame. Approximately 125,000 linear feet of 25-pair Category 5 UTP cable was purchased to run the backbone to the main distribution frame. The cable was originally specified as plenum cable, but Sullivan & McLaughlin suggested that it be changed; consequently, riser cable was installed in conduit, resulting in a substantial cost savings.

Technical staffing

A Category 5 installation is significantly more labor-intensive than a Category 3 or 4 job, and there was some concern about the level of technician expertise required. The cabling contractor therefore decided to increase the number of technicians on site, and the typical crew ratio of one technician to one apprentice was modified to 2:1 at MITC.

Because training is critical, all of the installers who work for Sullivan & McLaughlin are either presently enrolled in, or have graduated from, the International Brotherhood of Electrical Workers Local 103 telecommunications training program (see "Meeting Skilled Workforce Requirements," above).

An additional consideration for the cabling contractors was that MITC was a state-contracted project with specific staffing goals and requirements. For example, the contract specified that the cabling contractor would work toward a representation goal of "40% local residents, 20% minority and 10% female employees." With help from IBEW Local 103, the cabling contractor met all of these conditional staffing mandates.

Installing a high-speed network

Once the staffing issues were resolved, the installation of this high-speed communications system began. When completely installed, the network is designed to provide connectivity and high-speed transmission for 4000 terminals, or personal computers, and an equal number of phones. A fiber distributed data interface-compliant 24-fiber backbone connects the cabling system and provides linkage for the crossconnect and rings.

"The main distribution frame," says Mullally, "is essentially a passive crossconnect of a universal wiring system, which will provide flexibility for the future."

Each of the intermediate distribution frame closets contains a 24-fiber cable for high-speed data transmission, at least four Category 5, 25-pair cables for data applications and, depending on the number of end users, 10 to 40 25-pair cables, providing a dedicated voice backbone. Each of the closets also contains at least two 7-foot racks.

"The second rack is for expansion," says Hazley. "The closets will eventually have more racks, depending on the size of the floor and the user needs on each floor. We don`t know the exact requirements for end users," he adds, "but we`ve done some planning for future equipment and cabling."

Category 5 was chosen across the board for this project because, says Mullally, "Category 5 is the highest level of performance for UTP cabling today. While its use may be slightly overkill for voice, the system is structured for more-powerful applications in the future. This system will serve the small, low-speed networks or a larger, high-end one requiring 100 megabits per second [transmission] to the desk."

A voice/data integration scheme was established in each of the telecommunications closets by crossconnecting all of the four-pair voice cables--a procedure quite different from the typical one-, two- or three-pair crossconnection scheme. By doing this now, the installer company believes that future changes will be easier at the main distribution frame instead of at each of the intermediate distribution frames. This emphasis on future cabling extended to the cabling team`s leaving more than 3000 spare four-pair unshielded twisted-pair cables throughout the building.

Cabling an office building of this magnitude requires many skills, including attention to detail. For example, in the telecommunications closet, "each voice and data cable must be readily identified," says Hazley. "It has to be a unique numbering system. I avoid using two numbers on the same jack and don`t use As and Bs--that is, 123A and 123B."

As with most projects this size, certain operational problems surfaced as the project advanced. "In a job this big, you have to pay attention to the little things," says Mullally.

One such problem surfaced when it was time to run the vertical cables to the main distribution frame. After deciding that 25-pair non-plenum cable met the specifications, the installer company finally located cable with Underwriters Laboratories` verification. This 0.65-inch diameter power sum 25-pair cable had to be run in conduit to the individual closets.

"Category 5 cable, especially backbone, is physically bigger [than other categories of cable]," says Hazley, "and the conduit that holds the cable is 4 inches in diameter. It took a lot of sweat to install the backbone through to connecting closets, not only because of the sheer size and weight of the cables running through the conduit, but also [because] the building was approximately 80% complete, and there were significant obstructions."

Another problem was that every closet had a junction box outside it, installed above the ceiling. "We had to be careful running the lines at these points," says Hazley. "We tried, wherever possible, to pull right through the box, to avoid tight pulls or any damage to the cables."

A more serious question was whether to install the communications cables into the modular furniture systems. After assessing the drawbacks associated with this interface--potential electromagnetic interference, for instance,-- the cabling contractors, with approval from the design team, decided to terminate the telecommunications cables in floor box outlets.

Each pair of voice/data cable runs from closets under the raised-access floors and branches out from centrally located distribution points to the work areas. As many as 100 workstations were positioned in a typical open office area at MITC, with floor outlets positioned under each desk for the cables. Each outlet contained a gravity-fed, multiport angled coupler linked to a faceplate. A floor plate was positioned flush on the carpeted floors to protect the jack area. When terminating cables, installers stripped the cable back approximately 1.5 inches and placed the conductors into the 110 strips, while maintaining pair twists to within 0.5 inch of the point of termination. Each RJ-45 jack was then marked, color-coded and labeled.

A slight problem occurred, however, when some of these floor outlets were cut too close to the front of the workstations, increasing the likelihood of wire damage from users. Before installers terminated the cable at these points, the flooring contractors had to relocate these outlets under the desks to where the cables would be less vulnerable to tampering or physical contact.

Certifying the system

After the cabling was installed and terminated at the outlets, it was time to certify the system. The goal was to test the horizontal cable to meet Category 5 certification to 100 megahertz and note any deviations from TIA/EIA-568A standards for transmission requirements.

Sullivan & McLaughlin installers performed bidirectional testing using handheld testers. They downloaded the results onto a laptop computer onsite. The information stored on computer disks was then submitted to the general contractor, Suffolk Construction.

"There is no question that computers simplify the extensive administrative efforts required in this field," says McLaughlin. "There`s still a ton of paperwork, but this industry, like others, is moving toward information management on disk. Storing test results on disk will also make any future re-engineering easier. The ability to take a laptop to the job site translates to savings in time, energy and money."

Meeting skilled workforce requirements

One local program that helped Sullivan & McLaughlin Communications Group meet its staffing requirements for the Massachusetts Information Technology Center, or MITC, project is headed by the International Brotherhood of Electrical Workers, Local Union 103 Dorchester, MA. The IBEW founded a $6 million dollar training center to provide local contractors with a pool of trained professionals skilled in handling the core requirements for telecommunications installation but flexible enough to adapt to an evolving industry.

Phil Mason, director of the training facility, developed an intensive four-year telecommunications program combining field and classroom instruction and offering graduates the opportunity for certification in the Commonwealth of Massachusetts. Specifically, students are required to complete 8000 hours of on-the-job training and 800 hours of actual classroom instruction. The core curriculum extends across a broad range of telecommunications areas, including fiber optics, local area networks, underground cabling and voice/data switching.

New classification of employee

In describing this emerging field of telecommunications contracting, Mason talks about Oa new classification of employeeO trained to handle the rigors of heavy cable yet versatile enough to deal with electronics and broadband transmission speeds. Asked where the industry is headed, Joe Gambino, training supervisor at the training center, says, OWe are slowly moving toward state licensing in Massachusetts in this field. It may even happen this year. At that point we?ll have an even more sophisticated workforce than we do now. The end users will be the ultimate beneficiaries,O he says.

Another way that trained personnel are added to the pool of telecommunications installers is through manufacturer training. In fact, Peter Charland, MITC?s mechanical/electrical design engineer, audited a certification program in 1994 by The Siemon Co. (Watertown, CT), the major supplier for terminating hardware at the MITC. Several installers at Sullivan & McLaughlin Communications Group have also benefited from this training and certification program.

Many telecommunications manufacturers are becoming involved in training and certification, including The Siemon Co., the major supplier for terminating hardware at the MITC. The training/certification program emphasizes professional standards consistent with those of the American National Standards Institute/EIA/TIA. The core requirement for this program consists primarily of a week-long intensive review of documentation and testing compliance with TIA/EIA-568A, 569 and 606 standards, followed by a four-hour exam.

During the MITC project, Siemon demonstrated its team approach to structured cabling management. This involvement began with a preliminary overview of the blueprints and continued with extensive ongoing support at the site, as required. In his assessment of the MITC project, Tom Nichols, Siemon?s northeast regional manager, says, OThere was a remarkable synergy at this project?the right design, materials and components, knowledgeable installers, teamwork and planning.O

Lead technician Brent Tocci of Sullivan & McLaughlin Communications Group Inc. installs a floor box at the workstation.

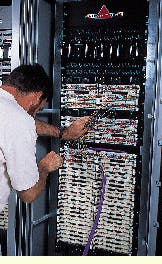

Field technician installs enhanced Category 5 cabling on the main distribution frame.

Peter Charland, RCDD, from the design team at Shooshanian Engineering (left) and Jay Burke, project manager from Sullivan & McLaughlin, discuss the merits of the expansion rack in the main distribution frame closet.

John B. McWalters, president of Words Inc., Salem, MA, writes business articles for trade magazines and offers marketing communications support to client companies.