Arlyn S. Powell, Jr.

From the standpoint of the end user and the cabling contractor, structured cabling systems are in transition. Although they are not yet completely resolved, many of the technological issues relating to them are well in hand. Electronic Industries Association/Telecommunications Industry Association-568, for example, has been recently updated, and a testing document, Telecommunications Systems Bulletin-67, is in the works. Other broader issues have been raised during the process of working out technical details; now installers and users are concerned about long-term warranties, installation training and certification programs, and how both are affected by such factors as materials shortages.

According to Todd Harpel, supervisor of technical support at The Siemon Co. (Watertown, CT), "Most of the technical issues with cabling and connecting hardware have been ironed out. Manufacturers have benchmarks to which they can compare their products, and nobody can make false claims, because Underwriters Laboratories has a testing program that can verify transmission performance, as well as electrical performance."

Harpel adds, however, that there are still several technical issues cabling installers should be aware of, including installation practices and handheld tester specifications. "One of the biggest concerns," he says, "is installation practice for a Category 5 system--maintaining your twist right out to the point of termination, maintaining the bend radius of the cable, not kinking it anywhere in the horizontal run. Also, you need to make sure that the cable route is not too near power equipment, unshielded power cables or fluorescent lights."

Standards questions

During the last year and a half, several handheld local area network cable testers have been introduced to meet recent end-user demands for certification of their cable plant upon installation. These testers are capable of measuring performance characteristics up to the 100-megahertz frequency specified by Category 5, but unfortunately, the performance characteristics and an agreed-upon methodology for measuring them have not yet been finalized into a standard. A TIA committee is working on TSB-67, which may be issued later this year, to address these questions.

Harpel claims that extended-frequency testing is also an issue. "A number of companies have tested their connecting hardware and cable beyond 100 MHz," he says. "They have reported favorable results, but because there is no benchmark beyond 100 MHz, there`s no way of telling whether these results are going to be good for real-life networks. Some concrete data is going to have to be produced to either refute or lend credence to these claims."

Other technical issues worth watching have to do with the use of stranded cables as patch cords, multiuser outlets in open-office environments and power and telecommunications cabling separation in modular furniture.

Although they are closely watching developments with handheld LAN cable testers, cabling installers seem to be less concerned about technology and more interested in business issues. Specifically, they are talking about extended warranties, the proliferation of vendor certification programs for structured cabling system installers and the effects of materials shortages on the availability of cable.

The 15-year (and longer) warranties being offered by many structured cabling system vendors have received mixed reviews from installers, perhaps because the warranties are so recent that all the kinks have not yet been worked out. In general, the warranties ensure defective cabling and components will be replaced without charge to the user if they fail over an extended period of time--perhaps 15 or 16 years. All of the components must come from a single vendor, and if the vendor itself does not manufacture the cable, then cable from a partner company or an approved cable manufacturer must be used. Also, the installer who puts in the system must be certified by the vendor.

These warranties have been criticized for having too many restrictions and for being unrealistic. For example, is the warranty invalidated if an end user uses uncertified internal personnel to make system moves, adds and changes? And what if the installer has gone out of business before a failure takes place? Furthermore, the average lifespan of a network is currently five to seven years, so any system installed today is unlikely to be in place for more than one-third to one-half the warranty period.

Training programs necessary?

Allen Kasiewicz, president at Trellis Communications Corp. (Manchester, NH), is an outspoken critic of extended warranties. "Everybody`s saying we have to go through a training program and get certified before we can use the 15-year warranty," he says, "but how many training programs do I have to send my technicians through to understand how to install cable? Besides, if you read the fine print in the warranties, you`ll see a lot of provisos and `thou shalt nots.` The warranties are too easy to void. And then, when cablers go out and sell these systems, vendors allocate the cable because of materials shortages. If you`re too small, you can`t buy direct from the manufacturer, and when you buy from a distributor, you have to take what`s on the shelf today. So you may not be able to get approved cable that can be warrantied."

Another warranty issue is discussed by Roger Foss, vice president at Frontline Network Systems (Northborough, MA). "For a manufacturer to offer a 15-year warranty on an $8 module is no great shakes," he says, "but for us to support that warranty is really a big-ticket item. We may spend a total of $180 in labor to replace that $8 component. The onus is really on the installer as opposed to the manufacturer." Foss favors the warranty program recently introduced by Panduit Corp. (Lockport, IL); it reimburses certified installers for labor when they must replace defective Panduit components.

All in all, and despite their criticisms, installers seem to view long-term warranties as a help more than a hindrance, though. They increase end-user comfort with an installation, and they foster long-term installer-user relationships, a definite benefit in today`s highly competitive market.

Certified installer programs

One vital component of long-term warranties is installation by a certified installation contractor. A frequent complaint voiced by installers, though, is that many vendor training programs are little more than sales seminars, with product presentations, a lunch and a certificate at the end of the day.

However, Tom Banks, president at MTS Services (Bedford, NH), was impressed with the installer training offered by Mod-Tap (Harvard, MA). "It really made me understand what Mod-Tap is looking for from a certified installer," he says. "Their product guidelines and the standards that apply were very valuable to me. The program is important enough that I`m sending all of my employees during the next few months."

Category 5 installations have been recently hampered by a shortage of plenum cable, because of a shortfall of fluorinated ethylene propylene used in its insulation (see "Help is on the way to meet the increased demand for Category 5 plenum cable," February 1995, page 55).

There are strategies for coping with the shortage, though. One strategy is to install structured cabling from a vendor that approves cable from a variety of manufacturers for use in their systems. Single-vendor solutions and component-cabler partnerships are more limiting in flexibility.

Another strategy is proposed by Foss at Frontline. "Try to sell your customers on equivalency," he says. "Get a specification that includes the phrase `or equivalent.` That`s where EIA/TIA guidelines have become so important. Now we can guarantee that anybody`s cable, regardless of manufacture, will meet Category 5 compliance as long as it`s properly installed. For 90% of our customers, equivalency is fine."

What does the future hold for structured cabling systems? Opinions are mixed about the future of copper. Jim Munton, marketing manager at Mod-Tap, claims that Category 6 may supersede Category 5 copper cable in the near future. "Rather than just being faster," he says, "it`s likely to be a shielded cable. The Europeans are pushing for Category 6 shielded cable." However, it will probably be met with resistance here in the United States.

Kasiewicz, a vocal fiber proponent, sees in the 15-year warranty "the death struggle of the copper industry. Cable manufacturers want end users to stay hooked on copper, and they`re using smoke and mirrors to get the users to do it. Fiber issues have been resolved, and fiber packaging is well-defined. We don`t have 20 different cable designs, as we do with copper."

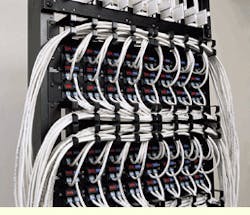

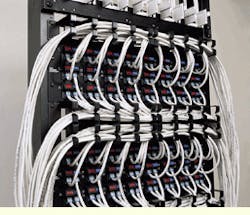

Siemon`s Category 5 CT panel with wire management organizes the cabling in the telecommunications closet. This kind of organization is one of the benefits provided by structured wiring systems.