Duff Campbell

Riser-Bond Instruments

Problem

When using a metallic time-domain reflectometer to test a cable for faults, the installer must know the correct nominal velocity of propagation of the cable (usually provided in the manufacturer?s specifications). By entering the correct nominal velocity of propagation, the TDR is calibrated to the particular cable being tested (see OMetallic TDRs provide accuracy for troubleshooting cable faults,O page 10). The nominal velocity of propagation can change with the temperature and age of the cable, however, and can vary from one manufacturing run to another. Even new cable can vary as much as ?3%. The variations in nominal velocity of propagation can therefore make it difficult to locate a fault.

Solution

To minimize the error in the nominal velocity of propagation (and to procure accurate distance measurements), the most common technique is to test the faulty cable from both ends. This technique does not work when testing or measuring good (no-fault) cable.

Procedure

1) Determine the path of the cable.

2) With a measuring wheel or tape, measure the length of the cable being tested.

3) Set the nominal velocity of propagation to the manufacturer?s specifications, test the cable from one end and record the distance reading (to the fault).

4) Using the same nominal velocity of propagation setting, test from the opposite end of the cable and record that distance reading.

5) Add the two measurements. If the sum of the readings is the exact length of the cable measured, the nominal velocity of propagation setting is correct and the fault has been located.

6) If the sum of the two readings is more than the measured distance, reduce the nominal velocity of propagation setting and re-test.

7) If the sum of the two readings is less than the measured distance, increase the velocity of propagation setting and re-test.

The same result can be obtained mathematically:

1) Take the actual cable length and divide by the sum of the two TDR readings obtained by the tests from each end. This gives the adjustment factor.

2) Multiply each of the TDR readings by the adjustment factor.

3) This result will be the corrected length reading.

Note: If the nominal velocity of propagation is not listed in the manufacturer?s specification, measure a length of good cable (no faults) and change the TDR?s velocity-of-propagation setting until the display shows the same distance reading as the measured length.

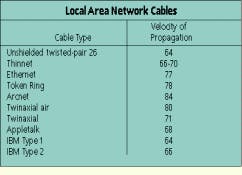

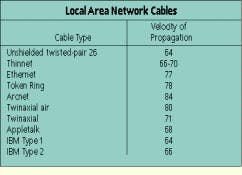

These examples show that different cables have different nominal velocities of propagation.

Duff Campbell, vice president for sales and marketing at Riser-Bond Instruments, Lincoln, NB, submitted this tip, which is excerpted from the company?s Product Catalog and Applications Guide.