Brian Reed, Mod-Tap Inc.

Problem

Preventing the spread of fire through fire barriers is a critical responsibility for cabling installers. In any installation, properly firestopping breached firewalls and floor-to-floor raceways is necessary. Following proper procedures and using the correct materials to seal these areas are imperative.

Firestopping through concrete barriers, installing wall boxes and using cable trays are the most common problems in this area. Firestopping cable trays is particularly difficult because of the irregular size and shape of the opening and the need to seal around the tray and any cables contained within it.

Solution

You must be able to select and install firestop materials properly to implement successfully a structured cabling system and to preserve the architectural integrity of the building design.

National fire codes define areas that must be firestopped, but a more reliable source of information is the local fire marshal.

Although mechanical systems have superior capabilities, they are often impractical or inappropriate. The use of nonmechanical systems of material--putties, caulk and foam--that are capable of fitting around or in irregular cables and pipes to seal off openings is more common. We recommend the use of a material that can be removed in case you eventually need to run more cable through the opening.

Procedure

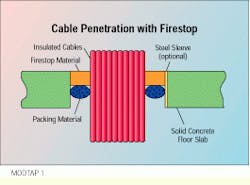

1) When firestopping through a concrete barrier, fill the opening with a fire-resistant packing material to within the manufacturer-specified distance from the edge of the opening. Then, fill the remainder of the opening with firestop material.

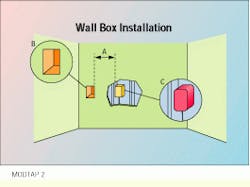

2) When installing a wall box in a fire-rated wall, it is acceptable to use a non-fire-rated box if it does not create an opening in excess of 16 square inches, or when there are a number of openings whose total area does not exceed 100 square inches per 100 square feet of wall area.

3) Wall boxes must be separated by at least 24 inches when there are two or more on opposite sides of the barrier. They must be plaster-sealed to the surrounding surface if the opening between the box and surface is more than 0.125 inches. They must also be sealed with firestop compound, such as putty or intumescent wrap.

4) Use intumescent wrap materials to firestop cable trays. They are pliable at room temperature, but swell and harden to fill the opening when they are exposed to fire conditions. Place the wrap on each side of the breached wall and around the tray and cables, filling any large openings between the cables and the tray. Then place additional strips around the opening to ensure proper sealing in the event of fire.

When penetrating a concrete fire barrier, use both firestop and fire-resistant packing material to close the opening.

Wall boxes on opposite sides of a fire barrier must be separated by at least 24 inches (A). They must be plaster-sealed to the surrounding surface if the opening between the box and surface is more than 0.125 inches (B). They must also be sealed with firestop compound, such as putty or intumescent wrap (C).

Brian Reed is a product manager at Mod-Tap Inc., Harvard, MA, a supplier of structured cabling systems.