Testing channel near-end crosstalk

Paul S. Kreager

KAI/Level D-1

The subtleties of testing Category 5 channels are just becoming apparent to those who design structured cabling systems and the installers and contractors who must test them. As Category 5 cabling systems have evolved, we in the industry have sometimes been faced with faulty and inoperative installations.

For example, many designers and installers have learned the hard way that you must be careful when terminating Category 5 cable. You must respect its bend radius and observe other rigorous installation practices; otherwise, some test parameter will read incorrectly.

We have also had problems developing meaningful standards, and the test instrumentation to validate systems to these standards has been slow in coming.

With Technical Systems Bulletin-67 nearly completed and handheld cable test instruments into their second generation, a sense of complacency is once more settling over the industry. However, let`s look at the following problem: We may have long channels, short channels, minimum-specification designs and higher-quality designs and still be Category 5-compliant. How, under these circumstances, can we ensure that proper installation has taken place and the channel has enough headroom over its lifecycle?

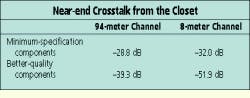

Consider, for instance, a problem with near-end crosstalk that you may encounter in real-world design and testing. Using a cable attenuation of -15 decibels per 100 meters, connector attenuation of -0.28 dB, minimum-specification cable and connectors registering -32 and -40 dB respectively, and better-quality cable and connectors measured at -38 and -60 dB, you perform near-end crosstalk testing from the closet for both long and short links. You use the channel configuration of Annex E of the Telecommunications Industry Association standard 568A (without a transition point connection); equipment cable length is 1 meter and closet patch cable is 2 meters long. Closet-to-work area cable lengths are 90 meters for the long channel and 8 meters for the short channel.

Suppose you choose a pass/fail method of testing this channel and set the toggle point of your tester at a channel near-end crosstalk of -27.1 dB. The following will result:

Y Choosing minimum-specification components for the long channel forces the contractor to use proper installation practice because there is only a 1.7-dB margin (28.8-27.1). With this headroom there is little room for craft error or the normal variances expected with test instrumentation and procedures.

Y Choosing better-specification components for the short channel results in headroom of 24.8 dB (51.9-27.1). In this case, despite the fact that improper installation practices may have been used, the channel will probably pass the usual tests, even if you are using second-generation test instruments. However, the link may fail when running certain applications during the lifecycle of the cable plant.Why? Because there is more to testing 100-megahertz copper-wire channels than just checking near-end crosstalk and attenuation. In this case, for example, improper installation practice could leave the circuit unbalanced; this might increase susceptibility to noise or lead to the problem of signals radiating from the cable plant.

A logical consequence of this scenario, although not necessarily a practical one, is that using better components may actually be a poor design decision, because the extra headroom provided may mask other problems that will surface later, when other applications are run on the network.

So what would be a good solution to this problem? One answer is not to use a single absolute value against which to test channel near-end crosstalk. Perhaps there should be several numbers, depending upon channel length, component specifications and other factors. However, with the cabling industry leaning toward single-number benchmarking, you are likely to find that installers will be unwilling to agree to near-end crosstalk values better than those in the standards documents.

Paul S. kreager is an independent consultant (KAI) and educator (Level 0-1 Telecommunications Education). He chairs the TIA-569 pathways and spaces and the 606 administration standards committees and also sits on the 568 cabling and 607 grounding and bonding standards committees.