John H. Mayer

Category 5 testing is the place to be in the 1990s. Driven by an industry-wide conversion to local area network-based client/server computing models and the emergence of new, high-speed LAN technologies, more than 30 million new Category 5 cable runs were installed worldwide last year. Analysts and vendors expect that number to jump to more than 100 million installations each year by the end of the decade.

Key to the rapid growth in the use of Category 5 cabling is the adoption of telecommunication systems bulletin (TSB) 67 of the Telecommunications Industry Association (TIA, Arlington, VA). This specification defines required test functions, test configurations and minimum tester accuracy for certifying Category 5 cable in the field.

The emergence of solid guidelines for Category 5 testing and certification has ignited an escalating demand for such services from the customers of cable installers and contractors.

"With the passage of TSB-67, there`s now a recognized need to test all new Category 5 cable and, looking out over the next few years, the trends that make cable testing important are intensifying," says Peter Williams, president of Scope Communications Inc. (Northborough, MA). "We expect that approximately 90% of Category 5 cable being installed will be tested."

Jostling to meet that need is a new generation of TSB-67-compliant testers from five vendors: Datacom Technologies (Everett, WA), Fluke Corp. (Everett, WA), Microtest Inc. (Phoenix, AZ), Scope Communications and Wavetek Corp. (San Diego, CA).

Starting with the basics

The cross-industry study team of the TIA and Electronic Industries Association (Arlington, VA) that came together in 1993 to work on TSB-67 eventually defined the following four cable parameters for Category 5 unshielded twisted-pair (UTP) copper cable, which comprise a complete test:

- A wire-map test checks twisted-pair links for pin-to-pin continuity from end-to-end.

- A length test verifies that the physical length of the link does not exceed that allowed by the standard.

- An attenuation test measures the reduction in signal strength over the length of the link.

- Near-end crosstalk testing measures the amount of signal coupling from one pair to another within a UTP cable link.

The TIA document also defines two test configurations: basic link and channel testing. A channel test covers the entire end-to-end installed link, including user cords at each end. Used more frequently by installers, the basic-link test is limited to horizontal cabling from the wall outlet or transition point to the first punchdown and the test equipment cords supplied with the field tester. All of the Category 5 cable testers provide the four required tests for basic-link and channel testing.

While not covered in the basic requirements of TSB-67, additional tests can be performed that can play a significant role in troubleshooting or certifying Category 5 cable. For instance, almost all of the Category 5 testers available today can also measure attenuation-to-crosstalk ratio (ACR), propagation delay, impedance anomalies and impulse noise.

Automated features speed testing

But perhaps the most dramatic improvements in the present generation of testers are productivity features that can help installers simplify and speed up Category 5 testing. Automated test setups, menu-driven user interfaces, sophisticated reporting capabilities and intelligent software that identifies the likely causes of link failures are bringing Category 5 cable-testing capabilities to a broad range of new users.

"Up to this point, more than 70% of the people who have bought testers were what we`d call advanced users, knowledgeable about cables and networks," observes Chuck Citron, senior product marketing manager at Wavetek. "There`s a whole group of electrical contractors and installers who haven`t spent $3000 to $4000 to test cable because their customers haven`t asked for it. With the emergence of the standard, many customers are beginning to say, `If I`m going to spend $50,000 to $100,000 to cable my plant, I want to know that it`s certified and I`m getting what I paid for.` "

For most installers, the time it takes to set up and run a test is a major factor in determining their on-the-job efficiency. The latest generation of Category 5 cable testers offers an autotest capability that accelerates the time it takes to run a TSB-67-compliant test. Typical test times now run 20 seconds or less.

Installers say these kinds of automated features can play a critical role in keeping costs down. "My unit runs a test in about 14 seconds, and that`s a big deal if you`re testing thousands of cables," notes Kenny Miller, project coordinator for Professional Network Services (Roanoke, VA), a cable and LAN equipment installer. "The longer the test takes, the more time I have to spend standing around waiting, when I could be getting [other] things done."

Miller uses a Wirescope 155 from Scope Communications. The unit runs a TSB-67-compliant test in 13.7 seconds. "We had a couple of engineers spend about a year optimizing the speed of the tester and working on making the software as efficient as possible," says Scope`s Williams.

A word of caution

It`s dangerous, however, to simply compare autotest times of instruments. Some units perform additional functions that can result in slightly longer autotest times, but in the long run, these units may save the installer time and money.

Wavetek`s LANtek Pro Series, for example, performs an autotest in approximately 25 seconds, but it also runs line-map, direct-current loop resistance, length, capacitance, dual near-end crosstalk, attenuation and ACR measurements. It automatically saves the test results and increments to the next label. "It cuts down on work-flow time because the guy in the wiring closet just has to plug it in and hit autotest; the unit not only runs the test, but also saves it to the correct label and increments to the next one," says Citron. "It also prevents errors because if the user forgets to increment manually, he could end up writing over the previous test."

Combining functions

One of the most common accessories used by installers with handheld cable testers is a two-way radio. While radios are often needed for conducting cable tests, many installers note that they are expensive, require frequent recharging, are easy to misplace or lose and, in office buildings with a large quantity of steel, unusable due to poor reception.

Earlier this summer, Datacom Technologies introduced the first Category 5 handheld cable tester to incorporate voice communications into the tester. The LANcat Vx gives installers the ability to run two-way, half-duplex voice communications over the test link. The TSB-67 Level II-compliant tester includes a built-in miniature microphone and an industry-standard earplug with audio jack. The unit also features talk pair, auto-discovery, volume controls and call alert.

"After the test is run, the technicians can talk over the same link they`ve been testing, discuss the results and decide which network port in the office they`re going to test next," says Jim Bordyn, Datacom`s director of marketing.

There is also a general consensus that feedback on performance above 100 MHz can be very useful to the installer, particularly as cable vendors continue to bring to market products with performance well in excess of this mark. Fluke Corp., for instance, recently announced an upgrade to its DSP-100 tester that includes an optional measurement capability to 155 MHz, using ACR as an indicator of cable performance. And several vendors, including Scope Communications, indicate in their test results how much headroom results with each pass or fail.

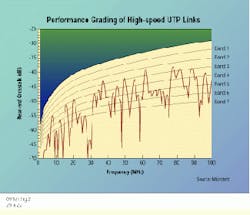

One of the more intriguing approaches to delivering this capability is a function provided in Microtest`s PentaScanner 350 tester--performance grading. To help differentiate high-performance Category 5 components, the PentaScanner 350`s performance grading defines Category 5 links in quality bands, each of which is 3 dB in width at 100 MHz. Each quality band represents a signal-power difference of two times the next lower. Performance is determined by worst-case peak values.

"If your customer has paid a few dollars more for premium cable, it`s not unreasonable that he wants to see evidence of that performance," notes Microtest director of technology development Mark Johnston. "The testers will indicate pass or fail, but it`s important to know if you`re barely passing Category 5 requirements or have tons of headroom for future high-speed applications."

The problem with a feature such as performance grading is assuming it tells you more about performance than it actually does. "In effect, if you have two pieces of cable, it tells you which one is better," says Wavetek`s Citron. "It doesn`t tell much about how it would perform above 100 MHz, because near-end crosstalk has an odd characteristic of spiking up and down. You could be in Quality Band 4 at 99 MHz, and at 101 MHz, you could spike up into Quality Band 1."

"End-users would be seriously misled if they assume using this test guaranteed that if and when there`s an industry standard for 350-MHz performance, their installation will meet that requirement," agrees Datacom`s Bordyn.

Delay skew rears its head

Another issue has recently surfaced for installers testing Category 5 cable. As the demand for cable has skyrocketed, so has the demand for Teflon, the insulating coating used on each of the four pairs found in the cable. To overcome a shortage of Teflon, many cable manufacturers recently turned to using non-Teflon coatings on one or two of the four pairs.

Known in the industry as "3 + 1" or "2 + 2" cables, these new products meet Category 5 crosstalk and attenuation requirements, as well as the fire rating required for plenum cable. But to the surprise of both cable manufacturers and users, the new insulating materials create a difference or "skew" in propagation delay for each pair.

Unfortunately, several popular new high-speed LAN technologies, most notably 100VG AnyLAN and 100Base-T4, transmit over all four pairs to minimize emissions and maximize bandwidth per pair. These topologies generally break the signal into several components, send it down the cable and then reassemble it at the far end. While built-in buffers compensate for small differences in propagation delay, these network architectures generally assume that the signal will arrive at the end of each twisted pair at about the same time. If the signals in a 100Base-T4 network, for example, arrive more than 50 nanoseconds apart, the buffer cannot keep up with the data flow, and information is lost. For 100VG-AnyLAN, a maximum limit of 67 ns is specified.

Tester manufacturers started hearing about the problem when customers called and claimed their testers were giving inaccurate readings. Most cable testers measure length by measuring the signal-propagation delay and using nominal velocity of propagation (NVP)--an expression of how fast signals travel in cables--to calculate length. The tester assumes that NVP is relatively constant from one pair to another in a cable. By altering the insulating material, the NVP from pair to pair changes significantly. So suddenly installers were recording readings that indicated one pair was a different length than another, simply because the NVP changed.

After testing cables from a number of manufacturers, tester manufacturers such as Microtest found some failed the skew requirement for 100Base-T Fast Ethernet. "The problem for installers is that they can now buy Category 5 cable, use Category 5 connectors, install them as recommended by TSB-67 and TIA/EIA-568A, test the link with an approved Level II tester, and it will meet all Category 5 requirements--but it won`t run high-speed data," notes Microtest`s Johnston.

Skew compensation

The propagation delay-skew issue is expected to intensify as network architectures attempt to squeeze increasingly more bandwidth out of their cable by transmitting in parallel over multiple pairs. To compensate for the problem, tester vendors are adding skew capability to their products. The Wirescope 155 from Scope Communications, for instance, offers a skew reading that will identify cables that could pose a problem to network applications. The unit independently measures one-way propagation delay for each of the four pairs and reports total delay and delay skew between pairs. The installer can then add a delay-skew specification into overall pass/fail requirements via an option in the autotest menu.

But industry observers agree that the ultimate solution to the problem lies with cable manufacturers. In a meeting last June, the TIA drafted a proposed change to TIA/EIA-568A that would strengthen present propagation-delay guidelines and add delay skew for 4-pair cables for all recognized cabling categories. The new requirements apply to qualifying cables in a laboratory environment with a network analyzer and not to field testing.

"I think the issue will receive a lot of attention over the next several months because there`s a lot of cable out there that doesn`t follow any particular standard," says Citron. "But as cable manufacturers bring to market cable that meets the new requirement, I think the issue will become less important." q

John H. Mayer is a freelance writer from Belmont, MA, specializing in computer and networking issues.

By grading link performance into seven quality bands, each 3 dB in width at 100 MHz, the makers of Microtest`s PentaScanner 350 argue that it can more accurately gauge performance characteristics than a simple pass/fail test permits.

Category 5 Handheld Testers

A free upgrade to Fluke Corp.`s DSP-100 Digital LAN CableMeter extends measurement capability to 155 MHz and measures delay skew.

Introduced in August, the LANcat Vx from Datacom Technologies integrates voice capability for two-way communications over the test link.

The LANtek Pro XL from Wavetek accelerates Category 5 cable certification by performing an autotest in less than 25 seconds.

The PentaScanner 350 from Microtest goes beyond traditional pass/fail results by offering performance grading, a function that quantifies the relative quality of Category 5 links.

To ensure compliance with the TIA`s TSB-67 Level II requirements, the WireScope 155 from Scope Communications is the first Category 5 handheld field tester to be certified by ETL Laboratories, an independent testing laboratory and subsidiary of Inchcape Testing Services NA Inc. in Andover, MA.