Tightly-paced project solves three problems for credit union.

Gary Null / Krone Inc.

In most companies, moving people, furniture and equipment has become a way of life. On average, companies reconfigure or churn their furniture systems once every two years, and reconfiguring more than 65% to 75% of a firm's people and furniture a year isn't uncommon. While studies show that a typical company reconfigures at an average of 45% to 55% each year, some companies reach a dizzying 150%.

Restructuring most modular furniture cabling systems is highly inefficient because most modular panels are bound together with home run cables. As a result, moves, adds and chances (MACs) could mean replacing the entire length of cable-incurring substantial material and labor costs. In fact, it is estimated that recabling during furniture MACs adds $200 to $500 per office cubicle. And that doesn't include the loss of employee productivity incurred during the process.

When Lockheed Federal Credit Union required additional space in its 13-year-old Burbank, CA headquarters to accommodate a growing number of employees, its solution also wound up providing employees with comfortable, ergonomically designed workspaces, plus an easily adaptable communications system that promised handsome financial benefits for years to come.

The company chose to totally replace its existing workstation setup with Haworth (Holland, MI) modular furniture featuring Krone's (Englewood, CO) DataThing cabling system.

Three problems, one solution

"Actually, we had three problems," explains Milton Callan, Lockheed Federal's assistant vice president. "One, we had to reduce the amount of space the workstations took up in order to accommodate 60 additional people in our over 200-person headquarters workforce. Two, our furniture, which was purchased in 1987, wasn't meeting today's ergonomic standards and was not very easy to move. And three, we wanted to increase our cabling capacity and take our cabling system into the 21st century.

At the Haworth/Krone showroom in Los Angeles, Callan says Lockheed saw the solution. "We realized that the Haworth modular panels that included the Krone cabling system met both our space and ergonomic needs. What's more, we could install Category 5E cable within the panels, answering our cabling concerns. DataThing would make moves, adds, and changes so simple that we could eliminate a lot of the technical support previously needed because we couldn't do the job ourselves. We were pleased with the testing that had been done, and the fact that the system was already being used by the U.S. Forest Service helped with our decision."

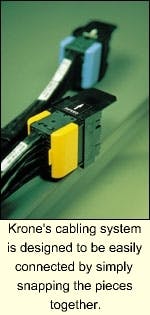

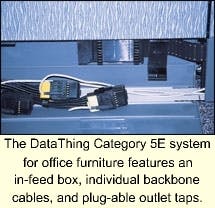

At the center of the DataThing cabling system is a modular backbone that lets components be easily connected when installed, and just as easily disconnected and reconnected when restructuring during MACs. DataThing meets Category 5E UTP requirements, and utilizes an in-feed box, individual backbone cables, and plug-able outlet taps-all of which can be installed without special tools.

The in-feed box is similar to power in-feeds, and is the connection point of the panel system to the horizontal cabling from the telecommunications closet. It can be mounted on panels or on an adjacent structure, placed in the communications closet, or hidden within the furniture panels.

Individual backbone cables called Communications Distribution Assemblies (CDAs) come in lengths that match the standard widths of Haworth panels. Each CDA contains six four-pair, high-performing circuits. Krone HighTap connectors on each end of the CDA snap together without special tools. Typically, three CDAs are used to form an 18-circuit backbone.

The plug-able outlet taps, which are similar to programmable receptacles, plug into the CDA to provide voice and data outlets for the equipment. Each outlet consists of a high-performance cable that's factory-terminated to a Krone jack on one end, and a Tap Fin connector on the other.

The task at hand

Pacific Coast Cabling (Chatsworth, CA) was selected for the Lockheed installation. The company provides a broad range of connectivity solutions to a client list that includes entertainment, professional services, academic, and financial service companies nationwide. Heading the Pacific Coast team was veteran project manager Jim Luman, who brought 22 years of experience in dealing with the complexities of hundreds of cabling installations.

One criteria for the installation was a vendor that could meet strict deadlines yet still have the flexibility and sensitivity to work around the operations of a fully functioning financial institution. Beginning Sept. 11, 2000 and ending no later than Oct. 28, Luman and his team needed to install 292 Haworth Premise Enhanced workstations equipped with DataThing. Workstation sizes varied from 6x6 to 6x8 and 8x12. The 75,000-square-foot building featured a main distribution frame (MDF), and two intermediate distribution frames (IDF) per floor, plus a Robertson Deck System that carried cables beneath the floor.

Luman says that Callan and his staff, led by project manager Judy Barrick, did an excellent job of staging the installation ahead of time. They briefed all the people involved as to what was expected of them, and when and how everything would occur.

"We worked in phases, with each phase normally including about 40 workstations on one floor," says Luman. "Lockheed Federal had two large conference rooms on the third floor that they furnished with stand-alone desks as temporary workstations. We installed interim wiring there so that the employees could work while their new workstations were being installed."

On the Friday before a group's installation phase was slated to begin, Luman says everyone in the group was brought to the two conference rooms and outfitted with PCs and phones. "They worked here from Monday through Thursday while we installed their new workstations and wiring. The following Friday, the group returned to their work areas. We did this for about eight weeks until all the workstations were installed, and it resulted in a minimum amount of employee disruption and downtime."

Beating the clock

Luman and his team made every effort to complete the installation efficiently and to meet Lockheed's Oct. 28 timetable. "Our goal was to work as quickly as possible, but at the same time not to disrupt the company's operations," he explains. "It really helped that their team was very organized and communicated well with us. This made it much easier to handle things before they even came close to turning into problems."

The installation team reconfigured two IDFs per floor, setting up six Krone punch blocks per closet and then setting up the main cables for voice, LAN, and a DEC (the former Digital Equipment Corp.) connecting system. Horizontal cable ran from the IDFs to each workstation via main header trenches within each floor.

"What we did was come out of the floor and into the face tray, which is in the furniture," Luman says. The cables snap-fit into the in-feed box and were punched down. "We put them [in-feed box] under the workstation where the knee access is, at the very back so that they're easily accessible," he added. "The CDAs then snapped in and fed to the cubicles. An outlet tap assembly (OTA) plugs into the CDA and provides outlets for equipment. A total of 877 OTAs were installed."

Most workstations received voice, data and DEC via three Krone Category 5E cables. DataThing is available in pre-set lengths to match the furniture panel width. For this installation, Luman's crew used mostly 36-inch and 72-inch lengths.

Crew size depended on the complexity of each phase, with six installers per phase being typical. "The installation may have taken a little more time," Luman explained, "but the product is more user friendly down the road. The user can easily change configurations; as far as what jack works what, they can change it in the CDA. And when it's time to move an employee or equipment, they simply untap and retap into the backbone at the new location. The system may be a bit more labor-intensive at the start, but it will certainly save the customer in the long run."

From Lockheed's perspective, space is no longer at a premium, employees are pleased with their ergonomically designed workstations, and the company can now handle MACs on its own. "The way it's designed," says Callan, "I could probably go and do it myself. We haven't done any cost studies on what the savings would be. Before this installation, however, we had to rely on outside personnel to come in and handle everything."

Callan was pleased with the way in which Pacific Coast Cabling was able to work within Lockheed's time and employee relocations parameters. While these issues can prove to be a sticking point between client and vendor, Callan says, "We were so impressed with Jim Luman, we awarded him with a vendor appreciation plaque."

Gary Null is advertising/communications manager at Krone Inc., Englewood, CO. You can reach him via e-mail at: [email protected].