A fiber-optic and Category 5E local area network gives this Pennsylvania lumber mill a competitive edge.

Catherine Varmazis

Nestled in the wooded hills of northwestern Pennsylvania, Bradford Forest Products (BFP--Bradford, PA), a division of Danzer North America, produces customized lumber for customers such as Ethan Allen Furniture. Like many market sectors, the timber industry is undergoing globalization. Operating in global markets requires more efficiencies and faster communication than before, as well as conformance to U.S. and international environmental regulations.

The idyllic setting belies those pressures and the technological changes under way at the 10-year-old lumber mill, one of several in the region. Last year, faced with a growing need for faster, more-efficient communications with sister companies in Darlington, PA, Indiana, and Canada, BFP management determined that its existing wide-area-network (WAN) connectivity via coaxial cable and dedicated 56-kilobit-per-second leased lines had to be upgraded. This upgrading would allow much faster communication with all the divisions that form Danzer North America, a German-owned company. At the same time, the internal communications needs of BFP were fast outpacing its infrastructure. A computerized system was in use that processed bar-coding data and let operators enter log-grading and tracking information, but it could not keep up with the company`s growth. Furthermore, as Windows-based applications became mission-critical to the company, it became clear that it needed a local area network (LAN).

"Originally, we were connected to an IBM AS/400 in Indiana through a coax line," explains Carl Stevens, director of finance and administration. "A Perle terminal control unit and a Black Box line splitter regulated traffic to and from the WAN. We had no LAN and we wanted to install a new Oracle system for the timber department to track inventory. The existing system had been cobbled together over the years and was unreliable."

BFP consulted with vendors, who recommended a client/ server solution. Working with systems integrator SuperUser Technologies (SU Tech--Bradford, PA), BFP decided to install a fiber-optic backbone to connect the four buildings on its 10-acre site as well as Enhanced Category 5 (5E) copper cabling for a portion of the network. Before the ink was dry on the network plan, the company decided to implement SAP, a sophisticated enterprise requirements planning software program. "In the past, when the salespeople in Darlington had a big order, they could not automatically access inventory data in Bradford," explains Carolyn Boser Newhouse, president of SU Tech. "They would have to call or fax over an order. Now they can go into SAP to put in an order. It figures out where the timber is going to come from, and it prints the order here. It streamlines their operation."

Local is better

Working with a local contractor was important to BFP because its remote location could make followup support and maintenance difficult. "We started taking bids and felt most comfortable with Carolyn`s company. She`s a local person, and all the people that were going to work on the network were local people," says Stevens. "I felt very uncomfortable with a company coming in from somewhere else, working on it, and disappearing with, `See ya later.` "

The speed of changes at the company made the network design a moving target, according to Stevens. "I`d say to Carolyn, `Remember how I told you we needed six workstations?` " recounts Stevens. " `Now we need 24. And we need to maintain our connection to the AS/400, and we need this and this....` It was reasonably organized `scope-creep,` but it changed the cost and the solution because we started with a six-person network, and next thing you know we`re talking about a WAN, connecting to an AS/400 in Pittsburgh, and so forth."

The company`s traditional network applications were e-mail and data sharing, but implementation of SAP and the Oracle timber system required more bandwidth than originally envisioned. Unlike most other businesses, which add value to discrete components by assembling them into a finished product, a lumber mill adds value by taking a tree and cutting it apart. "It`s like buying a bicycle, tearing it apart, and selling the parts," explains Stevens. "The veneer business is even more complex because you have to know which bike all those parts came from."

While SAP can track these details, such a complex application shared among the enterprise and LAN requires plenty of bandwidth and reliable operation. Hence, the decision to implement fiber for most of the LAN. "It was a balance between cost and scalability," says Newhouse. "This network runs at 100 megabits per second and it`s switched, which is key."

The design called for 3685 feet of Siecor FREEDM indoor/outdoor multimode cable for most of the premises and campus runs. This loose-tube cable was selected because of its ability to perform in both indoor and outdoor environments. Traditional outdoor cable is not riser-rated--a requirement for this project. Therefore, steel-rigid conduit or a transition splice would have been necessary had outdoor cable been used. On the other hand, indoor fiber-optic cable is not water-blocked and lacks UV protection. These factors made indoor/outdoor cable with water-swellable strength members the best choice for this application. A recent flash flood that dumped five inches of rain in an hour on Bradford and damaged several businesses did not disturb the underground plant.

For the portion of the network in the dimension mill, BFP`s maintenance department installed 4000 ft of Category 5E cable by Belden Wire & Cable Co. All of the applications go over the copper and fiber to "hit" the file server.

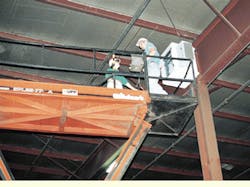

In the main crossconnect, which is located in the sawmill, SU Tech installed a 3Com 3000 switch and a Cisco router that connects to Darlington. Radiating from the main crossconnect, fiber and copper cabling are installed overhead. To reduce costs, the client opted to lash the fiber-optic cable to existing steel structures. Because this is a riser area, the solution was acceptable.

LAN is indispensable

Today, a sophisticated data-communications network is a strategic tool in any business`s arsenal. "We`ve cabled a lot of lumber mills in the area," says Newhouse. "Our clients understand the impact of a top-notch network on the bottom line."

While SAP implementation has been top priority at BFP, the new timber-tracking software that will soon be implemented over the LAN will use bar-coding and other computerized techniques to improve inventory tracking from the logyard to the lumberyard.

Is Gigabit Ethernet in BFP`s future? "I don`t think you can ever run too fast," says Stevens, "but the bottleneck for us right now is processor speed. It sure isn`t the network. When we get every company running data on the network, firing production data across it, we might need Gigabit Ethernet."

Fiber-optic cables leading from the sawmill to the dimension mill share the overhead trestle with steam pipes. Steam is used in processing lumber.

Carl Stevens, Bradford Forest Products` director of finance and administration, says he chose a local company to design and install the network because it was the most qualified and would also be available for support.

In BFP`s main crossconnect, systems integrator Carolyn Boser Newhouse points out that color-coding fiber and copper cables helps with identification.

A fiber-distribution cabinet in the sawmill is inspected by SU Tech`s Carolyn Boser Newhouse and BFP employee B.J. Sayers, who also maintains the copper portion of the local area network. Because of copper`s distance limitations, this cabinet was installed to provide network access to the building, primarily for members of the maintenance department.

From turn-of-the-century to state-of-the-art

Not every corporate headquarters can boast secret passageways and slatted peepholes. But when systems integrator SuperUser Technologies Inc. (SU Tech, www.superusertech.com--Bradford, PA) moves into its new headquarters, these "amenities" will come with the package. That`s because the company`s headquarters will be a converted 1913 U.S. Post Office, which included such features as part of its employee-management strategy. When SU Tech moves into the refurbished building, the peepholes will be boarded up and fiber will be installed to the desk.

Why fiber-to-the-desk? "We`ll need the bandwidth," predicts Carolyn Boser Newhouse, whose company includes divisions for business software development and network systems engineering as well as a structured cabling division. Under the direction of Jim Newhouse, the company`s structured cabling division has already placed conduit for the cable, and the move is expected to take place by year-end.

Shown at BICSI in Nashville last June, Carolyn Boser Newhouse, president of SuperUser Technologies Inc., and husband Jim Newhouse, manager of the company`s structured cabling division, are converting an old post office building into their corporate headquarters.