A quadrant layout facilitates installation of a Category 5E infrastructure.

Arlene Franchini / Ortronics Corp.

Pharmacia & Upjohn, pharmaceutical manufacturers well-known for the development of Rogaine, could have found themselves in a hairy situation with their cabling infrastructure during the renovation of their 138,000-square-foot headquarters in Bridgewater, NJ. After the company acquired the facility from at&t, it gutted the entire building and began renovating it from the ground up. The only thing left intact was the superstructure. Construction was scheduled for a six-month period, and the cabling infrastructure had to be installed within a six-week window.

"The accelerated construction schedule left no time for error in the planning and implementation of our infrastructure," says Tony Donohoe, director of information technology for Pharmacia & Upjohn. "We knew we had to rely on our one-stop designers to put this whole package together and get the system installed right. Pre-planning was the keyword. Key vendor selection was the means," he notes.

The cabling infrastructure had to be compatible with Pharmacia & Upjohn`s switched 10/100Base-T Ethernet local area network (lan) and its private wide area network, which connects the company`s major research and development facilities in Kalamazoo, MI, Milan, Italy, and Stockholm. In addition, the system and its related products had to be flexible for the constant moves, adds, and changes associated with the firm`s growing presence in New Jersey.

Pharmacia & Upjohn chose R.G. Vanderweil Engineers (Boston), a consulting and engineering firm specializing in building services and communications engineering, to design the network, put the project out to bid, then select the team to install the infrastructure. "We were very aggressive in the design, development, and follow-through till the end," states Brent Davenport, communications project manager with Vanderweil Engineers. "We wanted to make sure we included everything so that the job could be built exactly to specification, on time, and within budget. To accomplish this, our rcdds [registered communications distribution designers] produced detailed design documents and specifications."

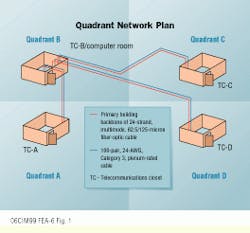

Quadrant plan

For easier cable-layout planning, the single-story building was divided into four quadrants--A, B, C, and D--each containing its own telecommunications closet (TC). Thus, a hierarchical star topology was engineered for the purpose of delivering services to each quadrant from the equipment room located in quadrant B. The building`s copper backbone cabling system, used for voice applications, consisted of multiple segments of Category 3, 100-pair cables, which were integrated into the horizontal cabling system within each quadrant`s respective TC. The building`s fiber-optic backbone cabling system, used for lan applications, consisted of one segment of 24-strand multimode, 62.5/125-micron cable and one segment of 6-strand singlemode, 8.3-micron cable. Once the backbone cabling was inside each quadrant`s TC, a networking device from 3Com provided connectivity between the backbone and the horizontal cabling system.

"The quadrants made it easy to treat each section as a separate entity, which simplified cable management in the closet," explains Donohoe. "The layout from Vanderweil was so well-documented that the installer, mehl Communications Inc. [Pearl River, NY], could easily adhere to the plans without any uncertainties or confusion."

Daniel Holland, senior vice president of mehl Communications, says his company responded quickly: "mehl maintains more than 100 installers from ibew Local Communications Union 164. Within 24 hours of the project award, we mobilized a foreman, Richard Imparato, and a crew of a dozen installers and got them on the job."

Construction was already at an advanced state when the installation contractor arrived on the job. Although Vanderweil Engineers provided detailed plans that defined the scope of the job, numerous issues still had to be addressed. "Our concerns were the coordination of our job with other trades` installations and working around the elaborate mechanical and electrical systems already in place above the ceiling," notes Holland. "Additionally, a 2x2-foot ceiling grid was already in place, including a slab height above the dropped ceiling of another 15 inches. A cable tray system was running through the primary areas. But, when cable had to run out of the tray, it required a time-consuming process to support the cable from the deck while still remaining just above the dropped ceiling height," he explains. mehl used a system of threaded rods and J-hooks to accomplish this task.

Within a six-week period, mehl built four TCs, one in each quadrant, and installed 3600 horizontal cables to the workstations, including six cables to each of the 600 workstation outlets. "Other than additional workstation outlets that were requested during the project, the plans were clear-cut, which made it easy to build the job as specified," says Holland.

To ensure rapid network response and headroom for future network growth, Vanderweil Engineers specified Enhanced Category 5 (5E) cabling in the horizontal. "We wanted to make sure that we specified a high-performance system that exceeded the standards set by the [Telecommunications Industry Association and the Electronic Industries Alliance]," explains Vanderweil`s Davenport, "so we specified the GigaMo system." This system includes modular jacks, patch panels, patch cords, and cable-management racks from Ortronics, as well as fiber-optic backbone cabling and lanmark 350 horizontal Category 5E cabling from Berk-Tek, an Alcatel company (New Holland, PA).

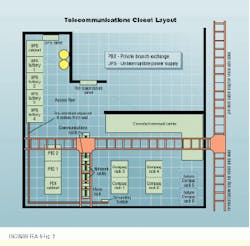

"To manage the fiber backbone, horizontal twisted-pair cabling, and coaxial cable to the conference room, as well as all the electronic equipment, we provided five Mighty Mo II cable-management racks per closet," states Larry Festa, president of C&C Sales (Westwood, NJ), manufacturer`s representative for the Ortronics product line. The racks house the hubs, routers, and switches that were relocated from the Kalamazoo facility, as well as the newly installed ormmac fiber-distribution cabinets and patch panels.

To connect the fiber backbone with the Category 5E horizontal cabling, high-density 48-port patch panels were installed in the racks. Horizontal cables on the patch panels were labeled to match the labeling at each workstation location. For example, if the horizontal cable is in Quadrant A, the label on the patch panel and on the workstation outlet would begin with the letter "A," followed by a number corresponding to a designated location.

"We provided both dual-gang Series II workstation outlets and Mini-Mod Innie modules to the workstations," says Festa. "This could give each workstation up to eight possible ports for data and voice, and a combination of both. Six horizontal cables were pulled to each outlet and two more are blank for future applications."

Down to the last wire

"When it got down to the wire, we were completing our cable scanning while the networking people were installing the equipment right behind us. There was no room for error, we had to be ready," points out Holland. "We stuck to the schedule and were able to complete the cabling installation, from tray to port, in the six weeks."

When a job is done within such time restrictions, quality is sometimes compromised. However, in this case, the specifications were so detailed and specific that the job could be done as specified, with no misunderstandings. "There was not one thing on the request for quote that wasn`t understandable," claims Donohoe. And to ensure that everything in the installation adhered to the standards, a representative from Vanderweil visited the site every other week to perform inspection and testing procedures.

"This was a model construction project," adds Davenport. "I have been on a lot of projects across the United States, and this was a prime example of teamwork at its finest." Donohoe agrees, "The precise plans from the designer, the right product mix from the manufacturer`s representative, and the `by-the-book` procedures of the installer gave us one of the most enhanced cabling systems available and delivered on time."

More growth expected

"A year ago, we estimated we needed to house 400 people," adds Donohoe. "But with the growth that the company had been experiencing, we knew we were quickly going to outgrow this facility. To prepare for the overflow, we installed two workstation outlets in 100 offices in case we needed to double up."

In preparation for its continued growth, the company has acquired a 550,000-sq-ft campus complex in Peapack, NJ. "We may have as many as 1100 people in New Jersey by year-end," adds Donohoe. "This campus layout will be more complex. Eight of the 10 buildings contain three stories. In addition, there is a complete underground system of two stories per building. Because of the success of the installation at Bridgewater, we will use it as a standard for future Pharmacia & Upjohn facilities. Although this installation was the epitome of coordination and teamwork, we may schedule in a little more time for wiring the next complex."

Collaboration between Brent Davenport (left), communications project manager at R.G. Vanderweil Engineers, and Daniel Holland, senior vice president of mehl Communications, ensured that the accelerated installation project was completed on time and within budget.

The design of the Pharmacia & Upjohn network called for a quadrant layout with a telecommunications closet in each quadrant.

A floorplan of one of the four telecommunications closets at Pharmacia & Upjohn head-quarters in Bridgewater, NJ, reflects the attention to detail that went into the planning of the company`s data-communications network.

A system of threaded rods and J-hooks was constructed to support the cable where it exited the cable trays.

Arlene Franchini is director of corporate communications and public relations at Ortronics Corp. (Pawcatuck, CT).