Michelle Abrams

Look around any modern-day office and you are likely to be faced with dozens of computer terminals, otherwise known as networked workstations, all connected by numerous cables. In fact, the immense growth in the data-communications industry is primarily responsible for the modern-day office place. As the cabling-support needs of industries and office places have changed over the past 30 years, mechanisms of cable support have adapted. One such support area, perhaps even the most prevalent, is the cable tray.

First introduced in the 1940s, cable tray was designed as a tool to meet the support requirements for existing types of cable such as electric power and communications. Today, tray is widely available and specifically designed to meet the needs of varying industries, ranging from paper mills to data communications (see Product Update table, page 112).

But what exactly is cable tray? According to the National Electrical Code (NEC), cable tray is "a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways." In simpler terms, cable tray can run along walls, ceilings, or other structures to provide the necessary support for cabling systems.

The Cable Tray Institute, an organization founded in 1991 to support the industry and serve as an industry marketing firm, has identified six types of cable tray currently in use: channel, ladder, single rail, solid bottom, trough, and wire mesh. Numerous cable-support applications are on the market, too. When examining all of these options, John Marlin, director of plant operations for Comcast of Garden State (Cherry Hill, NJ), says, "the best form of cable support really depends on the type of cable."

Marlin often finds himself using tray, but there are times when other support mechanisms prevail. "We use tray when we are using drop-wire in multidwelling buildings," he says. "How-ever, when going floor-to-floor, we prefer conduit."

Cable tray is the preferred support system among cable installers, primarily because of its cost-effectiveness and ease of use. The Cable Tray Institute notes that "cable tray provides the greatest versatility among cable-support systems, while offering savings of up to 84% in labor costs."

Choosing options

Ultimately, once the decision to use tray is made, the choice of which type of tray depends on the type of installation. Ray Colgrove, MPHusky's (Greenville, SC) inside-sales manager and chairman of a National Electrical Manufacturers Association technical committee, says installers should consider the type of cable, how often the structure allows the cable to be supported, and atmospheric conditions. While atmospheric conditions are not of primary importance for inside installations, they become a factor when supporting outside cable and in areas lacking insulation.

The physical structure where the cable will be installed also greatly influences tray selection. Locations available for support will affect the length, strength, and overall appearance of the system. Surroundings must also be evaluated in terms of environmental air handling, as this may indicate a need for various tray materials such as tray covers.

Price and availability are always a factor when choosing any product, but when it comes to cable tray, most products are relatively inexpensive and readily available. One additional factor, according to Don Sementilli, the Wiremold Co.'s (West Hartford, CT) product business manager of overhead systems, is "load ratings-how much cable weight the tray can hold." Various tray styles and materials are better-suited to support heavier loads than others.

Aesthetics are also becoming increasingly important in tray selection. With architecture becoming more open, and with designs inspired by infrastructure, the cable tray is often exposed. While this situation makes cable more accessible for maintenance, it also necessitates that manufacturers begin to take appearance into account.

Differing styles

Selection is plentiful in the cable-tray industry. All of the six standard types are available in various widths, depths, and lengths. The ladder-style tray is one of the most common and is made by nearly every manufacturer. Primarily constructed of steel, ladder tray is best used when cable systems call for maximum support that spans anywhere from 12 to 30 ft. Comcast's Marlin notes that like many installers, his company uses ladder tray to organize large bundles of cable that need to run overhead. In such cases, ladder tray is mounted to the ceiling.

But Wiremold's Sementilli sees a drawback to ladder tray since the cable must be run around the hangers on each side of the ladder. He favors the center-spine tray (also called the single-rail tray) because "the hangers are in the center, so you can put cables on either side." This makes for an easier installation process, he says, and lets the installer mount the tray closer to the ceiling.

MPHusky's Colgrove notes that single-rail tray products, like the company's Centray, have been around for close to 20 years, but the rise of the data-communications industry has created the need for more single-rail manufacturers. This tray style is most often made of aluminum, which is lighter and less corrosive than steel. Single-rail not only affords freedom for laying cable, but it is also one of the fastest systems to install in the field.

Another style of tray that affords field flexibility is the wire mesh or wire basket tray. Usually made of steel wire mesh, this tray is a straight section of easily cut wires, and can be cut and adjusted in the field. "It is really easy because a few clips and straights take care of it," says Colgrove. Primarily used for low-voltage telecommunication and fiber-optic cables, wire mesh is installed on short support spans of 4 to 8 ft.

The remaining three tray varieties are not as prevalent. Channel, solid-bottom, and trough trays are all designed to provide support for short to intermediate spans of 5 to 12 ft. The channel tray is typically used for installations with limited numbers of cable when conduit is undesirable, and is considered an economical choice for cable drops.

Solid-bottom and trough trays work best for cable used in applications that generate minimal heat. Both provide the stability and support necessary to protect delicate cable. Comcast's Marlin uses solid-bottom tray to support fiber-optic cable because it is an easy system in which to lay the fiber, and the bottom configuration provides constant support and protection. The typical design of the trough tray's bottom configuration provides support every four inches, as opposed to the constant support of the solid bottom.

Innovative styles

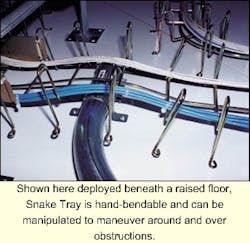

Some manufacturers are beginning to go beyond the six styles and stretch the definition of cable tray outlined by the NEC. One such example is Snake Tray (Deer Park, NY), which was founded by Roger Jette four years ago and has already grown into a multimillion-dollar enterprise. "Snake Tray was designed with 'what would the cable need?' in mind," says Jette.

The result is a steel tray that can be bent by any average-strength installer, as opposed to traditional tray that requires bolt cutters to cut and joints for reattachment. Much like the single-rail tray, all of Snake Tray's support mechanisms attach to a center spine. Jette points out, however, that "instead of having a flat tray, we made a J-shaped ribbed member that attaches to the spine every four inches."

Because cable tray hasn't changed all that much in nearly 60 years, one might wonder how the tray industry has advanced. New twists on the definition of cable tray such as the Snake Tray are examples of how the industry is pushing forth, although these static support mechanisms are making surprising advances elsewhere as well.

Manufacturers are offering various finish options, such as MPHusky's gold and Wiremold's stainless steel. "Some people really like the look and feel of steel, especially stainless steel," notes Sementilli. Jette says that aesthetics are an issue for only 2% of installations, but as architecture changes, this may change.

The ongoing metamorphosis of the office place will continue to be a factor in cable-tray development. Just as products like single-rail tray flourished side-by-side with the rise of the data-communications industry, additional trays will flourish to meet the needs of the office place. Colgrove believes the industry will not move away from the data-communications influence, but will build on it. He predicts the influence will come from the power industry and from Europe, where a new perforated style of tray is being developed.

One thing is for certain: Cable tray will continue to be a valued cabling-support mechanism, and manufacturers will continue to find ways to better meet the needs of installers by advancing the traditional design.