IVD manufacturing process maximizes bandwidth performance for voice, video, data.

John George and Michele Neifing / Lucent Technologies

There is much discussion in the networking and telecommunications industry these days about a converged network-one that carries all forms of communications, regardless of whether it is voice, data, or video. Fiber-optic technology, with its vast information-transmission capabilities, is at the center of this movement. Specifically, multimode fiber-the most cost-effective type of high-bandwidth fiber-is already playing a foundational role as the medium of choice for leading-edge networking technologies like Gigabit Ethernet.

This review of fiber-optic fundamentals and fiber-manufacturing techniques illustrates how this trend toward converged networks will affect the installation of fiber-optic cable.

Fiber optics basics

Optical fiber is a hair-thin strand of glass that transmits data signals in the form of light pulses. The fiber consists of a core through which the signal travels, and an outer cladding to confine the light signal within the core.

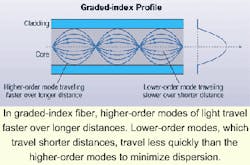

Each pulse of light in multimode fiber takes multiple paths, or modes, through the fiber core. Spreading or dispersion of the light as it travels down the fiber can cause communications errors at the receiver. Less light dispersion in a fiber increases the information-transmission capacity of that fiber.

Using a graded-index profile in the manufacturing process minimizes the primary cause of dispersion and optimizes multimode optical-fiber bandwidth. In this fiber design, the refractive index of the fiber core is graduated across the core. Accordingly, dispersion is minimized by speeding up the modes that travel longer distances (through the outer, low-index regions) and slowing down the modes traveling shorter distances (through the center, high-index regions). As a result, it is critical to maintain precise control of the refractive-index profile during the manufacturing of high-performance multimode fiber.

Several new technologies have been developed that can increase the information-transmission capacity of optical fibers. For example, network protocols such as Gigabit Ethernet use lasers instead of light-emitting diodes (LEDs) as a light source. Since lasers have a narrower spectral width and offer certain transmission advantages over LEDs, they cause less chromatic dispersion of light in the fiber. With less dispersion, the fiber is able to carry more information.

Until recently, lasers were at a price disadvantage when comparerd to LEDs. Fortunately, the development of vertical-cavity surface-emitting laser (VCSEL) technology has made lasers comparably priced with LEDs. In fact, the Institute of Electrical and Electronics Engineers (IEEE-New York City) committee responsible for the Ethernet specification wrote the standard to include VCSEL technology.

Another difference between LEDs and lasers is the launch condition of the light as it is placed into the fiber. LEDs use what is called an overfilled launch, in which the entire core of the fiber is illuminated. By contrast, lasers perform a restricted launch in which only a portion of the core is illuminated. A restricted launch is more demanding on the fiber's index- of-refraction profile. The use of laser transmitters in network protocols like Gigabit Ethernet is another reason why it is important to control the fiber's index-of-refraction profile during manufacturing.

Making fiber

There are three major steps in the fiber-manufacturing process: preform manufacturing, fiber draw, and test and measurement.

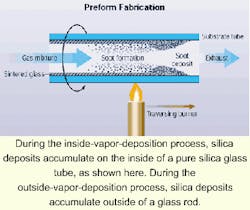

A preform is a solid glass rod made of ultra-pure silica, doped with germanium to create the required refractive-index profile. The most widely used process for manufacturing preforms is inside vapor deposition (IVD), a process that deposits the silica on the inside of a pure silica glass tube rather than on the outside of a glass rod. It is also possible to make multimode preforms using outside vapor deposition (OVD). Both processes involve deposition and consolidation of fine particles of ultra-pure germanium-doped silica.

Most fiber manufacturers have chosen the IVD process. By using IVD to manufacture preforms, it is possible to lay down hundreds of individual layers of glass, allowing for extremely precise control over the refractive index profile. IVD processes are also unique in that glass deposition occurs within an enclosed and tightly controlled atmosphere of the tube, allowing the atmosphere to be free of contaminants that can increase attenuation and lower the fiber's transmission performance.

The benefits of IVD are seen in the performance capability of the fiber it produces. It is possible to achieve peak bandwidths well in excess of 1,000 MHz-km with 62.5/125-micron graded-index multimode fiber. In addition, the IVD process's fine profile control produces multimode fibers that are capable of extremely high bandwidth (greater than 2,200 MHz per km), allowing transmission in the range of 10 Gbits/sec.

Drawing the fiber

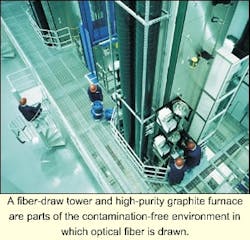

The second step in the manufacturing process is to draw out the hair-thin fiber from the glass preform. The preform is first installed at the top of a fiber draw tower. The tip is then lowered into a high-purity graphite furnace where the injection of pure gases ensures a clean atmosphere for the fiber-draw process.

Within the furnace, tightly controlled temperatures approaching 2,000°C soften the tip of the preform. The resulting molten glass is stretched into a thin strand that is threaded through a series of coating dies and wound on drums at the bottom of the tower.

The diameter of the fiber is continually controlled at 125 microns, with a tolerance of less than one micron. A laser-based gauge monitors the fiber diameter more than 750 times per second. The automated draw system maintains precise fiber diameter by making minute adjustments in draw speed as needed.

During the draw process, a protective coating is applied to the fiber. This dual-layer ultraviolet-cured acrylate coating provides mechanical protection for handling, while also protecting the pristine surface of the fiber from harsh environmental conditions.

Final manufacturing step

The spooled fiber is then sent to the test-and-measurement department, where mechanical, optical, and geometrical tests are performed to verify fiber performance. High-speed prooftesting, which is one of the primary mechanical tests, is done to confirm that the fiber's tensile strength is at least 100,000 pounds per square inch.

In addition to the mechanical tests, a series of optical measurements is taken at various wavelengths. Key optical parameters include

- Bandwidth-the fiber's information-carrying capacity;

- Attenuation-the decrease in signal strength over distance; and

- Numerical aperture-a measurement of the maximum light acceptance angle into the fiber.

Geometric measurements ensure the consistency of the fiber's core, cladding, coating diameters, and circularities. In addition, stringent environmental testing helps ensure the fiber maintains its optical and mechanical integrity under a number of adverse environmental conditions. Fiber is tested over a wide range of temperature and humidity extremes. Wet and dry coating strip-force testing verifies the protective ability of the fiber's coating and its ease of handling for splicing and connectorizing.

Industry standards like Gigabit Ethernet have been developed to increase the transmission data rates for multimode-fiber networks, drawing attention to the process used in fiber manufacturing. Previous fiber installations can be upgraded easily to Gigabit Ethernet, as long as the optical fiber was deployed in compliance with industry standards. The latest revision to the IEEE 802.3 Ethernet standard was intentionally structured to maximize compatibility with the installed base of fiber. The Ethernet standard supports a variety of link lengths that depend on the wavelength of operation and the fiber's core size-either 50 or 62.5 microns.

Eliminating centerline dips

The Ethernet standard also takes into account slight center perturbations historically found in fibers made from both the OVD and IVD manufacturing processes. Through enhancements to the IVD process, companies like Lucent have eliminated centerline dips-a source of these minor index-of-refraction perturbations. By removing center dip, the fiber's bandwidth performance is maximized because the IVD process is able to precisely control the index of refraction of the fiber. This consistently boosts the bandwidth of the fiber under the restricted launch conditions typical of high-speed laser-based systems, such as Gigabit Ethernet.

For Gigabit Ethernet installations using short-wavelength lasers as light sources, standard fiber distributed data interface-grade 62.5/125-micron multimode optical fiber supports up to 275 meters. For longer lengths, enhanced-bandwidth 62.5/125-micron fibers-like Lucent's GigaGuide, OptiSPEED, and Opti-SPEED Plus-support distances from 300 to 600 meters with short-wavelength sources. And for even higher bandwidth requirements, Lucent's recently introduced LazrSPEED 50/125-micron multimode fiber offers performance up to 10 Gbits/sec over 300 meters using VCSEL laser transceivers. All these fibers are made using the IVD manufacturing process.

Already the preferred process of most fiber manufacturers, the IVD process maximizes fiber-bandwidth performance and will continue to meet the exponential demands of voice, video, data, and other communications in converging networks.

John George is fiber-optic development manager and Michele Neifing is a marketing and communications manager at Lucent Technologies (Murray Hill, NJ).