The right equipment is essential to ensure your optical-fiber network will support the latest applications.

To be competitive, today’s enterprises require high-speed networks that allow efficient communication, both within the company and with the outside world. Whether they are small companies just starting out or Fortune 500 corporations, enterprises all need standard voice services as well as high-speed data services for e-mail and other high-speed applications.

But this extensive use of networks leads to ever-increasing bandwidth demand, as well as the need for a proper testing and maintenance plan. This article presents a brief overview of typical enterprise networks, and the main testing procedures and parameters-using an optical time-domain reflectometer (OTDR)-that will enable a network to operate efficiently.

Typical optical networks

With recent improvements and increased capability of Transmission Control Protocol/Internet Protocol (TCP/IP), we are witnessing a convergence of voice and data networks. Depending on the application and the area covered, networks include: traditional LANs, metropolitan area networks (MANs), storage area networks (SANs), and wide area networks (WANs). But no matter the network type, 10-Gigabit Ethernet (10-GbE) is becoming the technology of choice to fulfill the need for ever-increasing bandwidth.

Deploying 10-GbE is becoming popular because equipment costs are decreasing significantly, mainly due to the use of lower-cost, non-cooled optics and vertical-cavity surface-emitting lasers (VCSELs). Like Gigabit Ethernet, the 10-GbE standard (IEEE 802.3ae) recognizes copper and optical fiber as transmission media.

Optical fiber for telecom applications is made of glass consisting of a core and a cladding that propagates light by total internal reflection. Two main types of fiber support 10-GbE:

• Singlemode fiber, with a core size between 8.6 and 9.5 microns (µm), supports 10 GbE to a maximum distance of 10 kilometers (km) in the 1310-nanometer (nm) operating window, and 40 km in the 1550-nm operating window. Singlemode fiber typically is used in WAN, MAN, and SAN applications.

• Multimode fiber has a core size of 50 or 62.5 µm, which allows multiple modes of light to travel simultaneously (hence the name, multimode). It has limited distance capability compared to singlemode, and for a given distance, supports a lower data speed than singlemode due to modal dispersion and high attenuation. Multimode supports 10 GbE to a maximum distance of 300 meters in the 850-nm operating window, and is normally used inside buildings, data centers, and central offices.

Testing and qualifying the fiber

Fiber, like copper, must be tested and qualified after installation to ensure it is usable when it will be required. This is true whether the work is done by the enterprise employees or by hired contractors.

When qualifying a fiber link, the fiber, splices, and all connectors are measured and taken into account. The basic procedure to qualify an optical link is to use an a optical-loss test set (OLTS), which can range from basic portable optical sources and power meters all the way up to automated bi-directional units offering data storage and reporting capabilities.

There are, however, shortcomings and limitations associated with OLTS testing. First, an OLTS will not necessarily identify localized faults or problems. For instance, a link can show an acceptable overall loss, but have a bad or high-loss connector. Moreover, if a fiber link does not meet the required criteria, it is not possible to identify or locate a problem with an OLTS. Therefore, fiber cuts, bad connectors, bad splices, and macrobendings cannot be located.

A different instrument can help avoid all these shortcomings-the OTDR.

OTDRs in action

OTDRs are becoming more affordable than ever, and are providing more benefits as well. Among the better testing and qualification features offered with today’s OTDRs are single-ended testing (requiring just one technician rather than two); display of fiber “signature” trace, pinpoint event loss, attenuation, and reflection; post-processing of test results and complete report creation; and trace comparison with a reference acquisition. If used correctly, the OTDR provides all the information that an OLTS provides.

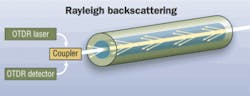

In basic terms, the OTDR sends pulses of light, which encounter reflective (Fresnel) and scattering (Rayleigh) events. A fraction of the pulse returns to the launching port. Measuring the difference between the launching time and the return signal’s time of arrival lets you determine the distance between the launching point and any optical event.

Rayleigh backscattering originates from every point along the fiber. Measuring this backscattering lets you determine the measurement of fiber attenuation.

Fresnel reflections are caused by abrupt changes in the refraction index (such as glass/air interface, breaks, connectors, and fiber ends). These reflections are seen as spikes on the OTDR trace and usually generate a substantial level of reflected signal power, as compared with the backscatter level.

OTDR’s testing requirements

But not all OTDRs are created equal, and not every OTDR will fulfill all the requirements of every job. So, consider these key specifications before buying:

• Dynamic range (in dB) is important because it indicates the OTDR’s measuring capability. Its value is obtained by calculating the difference between the launch level and the level where the signal-to-noise ratio equals 1. Having the largest dynamic range is not necessarily an advantage, because a large dynamic range may sacrifice some other critical parameters.

• Measurement range (in dB) is a specification rarely seen on a spec sheet. Although the dynamic range is the key specification, you must also consider the measurement range, which is defined by the maximum loss that can be inserted between the initial backscattered level and an event that the OTDR is still able to detect and measure accurately.

• Dead zones are naturally occurring phenomena when measuring fiber with an OTDR. The phenomena can be compared to the momentary reaction that occurs when you walk out of a building and are temporarily blinded by the bright sunshine. Similarly, dead zones temporarily blind the OTDR’s detector due to the high Fresnel reflection of a reflective event, such as a connector.

The event dead zone is the shortest distance between two optical events that the OTDR can detect. It represents the minimum distance required for an OTDR to detect a reflective event that follows another reflective event. Event dead zones are typically occurrences that result from each reflective event on a fiber span. When measuring an OTDR’s event dead zone, the shortest pulse width is generally used, because it gives the shortest event dead zone.

In theory, a 30-nanosecond pulse width would give a 3-meter (m) event dead zone, because in the OTDR world, the pulse can be thought of as having a length of 3 m. Other parameters, such as the receiver circuitry’s electrical bandwidth, can affect the event dead zone. Similarly, the strength of the measured reflective event can also affect the dead zone. A strong reflection (such as higher than -20 dB) can cause the detector’s circuitry amplifier to saturate and take more time to recover, thereby increasing the event dead zone.

The attenuation dead zone represents the minimum distance required for an OTDR to detect a non-reflective event following a reflective event. This zone is a physical phenomenon that occurs after the initial connection and after all reflective events along a fiber span.

High-reflectance measurement capability is an especially important OTDR characteristic in multimode networks, which often include connectors with reflectances as high as -20 dB. To properly measure the loss of a connector with such a high reflectance, the OTDR’s detector must not saturate below a value of, say, -18 dB.

Controlled launch conditions also require certain OTDR performance characteristics. The term “controlled launch conditions” refers to ensuring that the multimode fiber’s core is properly filled with light. Alternatives to controlled launch conditions are overfilled and underfilled. In an overfilled launch, too much light is sent through the fiber, and a large portion of it will be reflected from the original connector. In an underfilled launch (see figure, above), the light is concentrated in the fiber center, and insufficient light is sent through the fiber. The core is not uniformly or completely filled.

The problem associated with an underfilled launch is that a loss can be underestimated. For example, if two connectors are misaligned and an OTDR’s light source is underfilled, no energy will be reflected and lost. The OTDR will not detect the misalignment. To properly detect and measure these misalignments, an OTDR must have controlled, filled launch conditions. Conditions must be equivalent to those obtained by the standard OLTS procedure, which is to use an overfilled source followed by five mandrel turns on a cylinder of 25 mm for 50-µm fiber, or a 20-mm cylinder for 62.5-µm fiber.

Diverse capabilities

To be a reliable and practical tool, an OTDR must offer good specifications as well as have key enabling features, including:

• Multimode and singlemode capability-A good enterprise-network OTDR should let you test both fiber types with the same unit.

• Automatic modes for novice users-This capability lets you perform the tests without requiring in-depth knowledge of fiber optics.

• Advanced modes for expert users with specific requirements-These modes should have as many configurable parameters as possible to let you perform specific tests, according to particular requirements.

• Post processing-It is important to efficiently store results for future analysis.

• Report generation-The ability to create configurable reports that provide all the key information as well as the OTDR trace of each of the tested fibers.

In short-haul enterprise networks, it is especially important to measure the initial and last connectors. In optical-fiber links, optical loss usually originates from connectors, splices, macrobendings, and fiber attenuation. In long-haul or metropolitan networks, all these aspects significantly affect transmission. Over short distances, such as 50 meters-typically the case in enterprise networks-fiber attenuation does not have significant impact.

Unless there is macrobending in the fiber, the connectors will be the major contributor to the link loss. That is why it is crucial to properly measure them. In many cases, there will be just two connectors. In all cases, it is mandatory to properly measure the first and last connectors.

To properly measure the initial and last connectors, you should use launch cable reels (LCRs) before the first connector and after the last connector. This practice is required for obtaining accurate loss measurements, because it is necessary to have Rayleigh backscattering on a sufficient distance before and after the connector. Normally, an LCR measuring between 100 and 200 meters should be enough for any type of pulse.

For efficiency’s sake, some people prefer to test two fibers at once. This calls for a loopback connection between the two fibers. Again, to properly measure the connectors, you should use an LCR between the first and second fiber.

Up to the challenge

As higher-capacity private networks are built, it is important to fully test and qualify them to ensure optimal reliability. For a fiber-based network, different approaches are available to achieve that goal, but because an OTDR provides more information and troubleshooting capabilities, this testing device should be considered the instrument of choice for adequate and reliable testing.

BENOIT MASSON is with EXFO E.O. Engineering (www.exfo.com).