COMPILED BY PATRICK MCLAUGHLIN

UL requiring holographic labels on cable products

In an effort to fight the penetration of counterfeit cable into the communications cabling market, Underwriters Laboratories (UL) now requires manufacturers of communications cables bearing the UL mark to use holographic labels on the smallest unit container in which the cable is packaged. The requirement went into effect October 1 and UL required cable manufacturers to destroy all non-holographic labels by that date. The following cable types are subject to the holographic-label requirement.

- Communications cable

- Communications cable verified to UL Performance Category Program

- Data transmission cable verified in accordance with national or international specifications

- Community antenna television cables

- Data processing cable

- Non-power-limited fire-alarm cable

- Instrumentation tray cable

- Network powered broadband communications cable

- Optical fiber cable

- Power-limited circuit cable

The specific effort that has resulted in the holographic-label requirement dates back to the beginning of 2010, and likely earlier than that. In January UL issued a bulletin to what it describes as its subscribers: cable manufacturers that participate in UL's certification services programs. The bulletin contained a proposal to revise the requirements of the Mark Integrity (Follow Up) Programs for the above-listed cable types. Over several months after the proposed changes were made, UL held industry forums in the United States and China to gain feedback on the proposal. Individual subscribers not participating in the forums also provided comments. UL said the program it ultimately put forth incorporates some of the suggested changes requested by industry participants.

In a bulletin to subscribers providing detail of the revised program, UL stated that the use of holographic labels has proven to be an effective tool in deterring counterfeit products from entering the marketplace.

The UL mark that you often see on a cable's jacket will remain as it has been - the letters "UL" either within a circle or in parentheses. In a memo to subscribers, UL reminded them that the printing of the UL mark on a cable jacket is permissible only when the accompanying smallest-unit container (e.g. reel or box) also has the UL mark.

The image in the left column of this page is that of a sample holographic label UL included in a recent issue of its newsletter The Code Authority, a quarterly publication from UL's Regulatory Services Department meant as a resource for regulatory authorities. In the Code Authority article, UL explained that although manufacturers cannot add non-holographic labels to cable after October 1, it may take some time for cable with non-holographic UL marks to clear the supply chain.

In April 2009 UL's consumer safety director John Drengenberg told us that communications cable does not necessarily fit the typical profile of a product that is counterfeited most often. Typically, high-volume, low-priced items including consumer products like power strips, nightlights and decorative holiday lights are subject to counterfeiting. Those items carry the UL symbol on holographic labels for exactly that reason; they are the most frequently counterfeited items and counterfeiting a holographic symbol adds a layer of complexity that deters many potential perpetrators. Since the time that statement was made a year-and-a-half ago, communications cable obviously has climbed to a higher-profile position within UL.

The revised program includes other details about the procedures for UL's follow-up testing procedures of cable. In future stories, we will provide more detail on the program's changes.

For now, do not be surprised to see cable boxes and reels from familiar manufacturers now bearing holographic UL labels. In fact, it is probably worth questioning your supplier if the label is not holographic. Manufacturers were ordered to destroy non-holographic labels by October 1 and had the opportunity to order holographic labels beginning in June.

Magnetic cable-tray mounting systemA cable- and cable-tray mounting system from Metal and Cable Corp. (www.metal-cable.com) offers an alternative to welding and epoxy attachment methods by providing a non-penetrating solution to securely carry cables across and down the curvatures of steel water tanks. The system, called the Magnemount Cable/Cable Tray Holding System, was developed in response to the sharp growth in the incidence of cell phone antennas being mounted on water towers.

The concept for the system came about when a Metal and Cable Corp. customer wanted to design a cable-mounting system that could work either with or independently from the company's original Magnemount antenna-mounting system. The desired result was achieved using two Magnemount system magnets attached to a length of 304-grade stainless steel Unistrut.

Metal and Cable Corp. explains why its system is an attractive alternative to welding cable-tray supports atop water towers. "Whereas traditional welding methods present a permanent solution, the invasive nature of welding requires recoating the steel on the inside and outside of the water tower tank. This may involve draining and refilling the tank, along with other time-consuming and costly operations. Epoxy-mounting solutions are less invasive, but many factors can influence the reliability of this method as a long-term solution."

The company's president, and also Magnemount's inventor, David Klein states, "The Magnemount Cable Tray Holding System offers water municipalities a permanent, dependable, non-invasive solution that requires no maintenance or shutdown. Additionally, it provides cell phone companies with an option to present water municipalities who are averse to welding on their tanks."

The Magnemount system's design, which is patent-pending, conforms to the varying curvature of steel water towers. The design of the independently mounted magnets allows the mounts to be placed on steel towers or legs with as little as a 4-foot diameter, Metal and Cable Corp. says. When the tray holders are placed on the tower, it should not take more than a minute to make any necessary adjustment.

One option for attaching cable, the company points out, is to use the 304-grade Unistrut clamps to secure cables to the Magnemount cable-mounting system. Another option is to attach the cable/cable tray mounts directly to the cable tray, one on each end of each tray. When specified to be used with cable trays, 3- to 5-inch bolts are used. These longer bolts accommodate surface painting under the system on the water tower tanks, thereby eliminating the need to remove the system during the painting process.

Dow offering halogen-free compounds for cordsDow Wire and Cable (www.dow.com/wire) recently introduced Dow Sustain, a set of halogen-free compounds that the company says will allow electronics OEMs to make flexible cords safer and more environmentally sustainable than those made with PVC. However, don't expect the Dow Sustain technology to show up inside of patch cords used in structured cabling systems. Dow explained that the four product grades now available in sample quantities for jacketing and insulation are aimed at makers of wires, cables and cord sets for personal electronics, large and small appliances, televisions, DVD/DVR devices, gaming systems, and computers/monitors/USB attachments. That latter product set could be where the halogen-free products ultimately see deployment in LAN environments.

Dow is appealing to wire and cable manufacturers with its new product set, impressing upon them that the Dow Sustain suite exhibits good chemical resistivity, low corrosive off-gassing in the event of a fire, and flexibility that is essential for ease-of-handling during manufacturing as well as the overall look and feel of the end product.

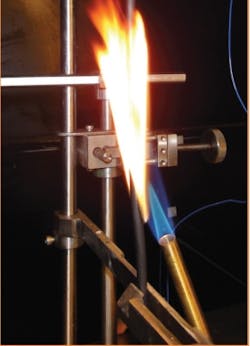

Simon Leung, Dow Wire and Cable's platform leader for personal electronics, explained the benefits of the Sustain products as well as the momentum that led to their development. "With the demand for PVC alternatives in an electronics market growing fast, Dow has made a significant investment over the last three years in perfecting halogen-free compounds. Dow Sustain is the first halogen-free offering qualified to meet UL 62, JCS4509 and HD21.14 requirements on a commercial scale while delivering excellent look and feel as well as enhanced product and extrusion performance." (The image on page 36 shows the European Union HD21.14 smoke-density test setup.)

The company says it worked with Shenzhen BaoHing Electric Wire and Cable Manufacture Co. as well as Volex to trial the new compounds. Both manufacturers were able to meet global standards using Dow Sustain, the company reports.

Volex is best known for its production of power cords. Vice president of global supply chain for Volex Group, Chris Rutherford, said, "Dow Wire and Cable has been a good working relationship with the product development and technical know-how to help us efficiently run their product. The new compound can achieve production rates similar to PVC with only minor investments for extruder screw design and drying conditions."

These new compounds for Dow will most often be found in consumer products with some appearance in desktop computing environments. In structured cabling environments, a set of halogen-free compounds was introduced by General Cable late last year. General's 17 Free product line currently features halogen-free riser-rated twisted-pair cables, and the company has said more halogen-free premises cable products will be coming soon.

Use your cell phone as a fiber-optic testerIn most cases, the tool used as a fiber-optic tester is either an optical-loss test set (OLTS), visual fault locator, or a higher-end device like an optical time-domain reflectometer (OTDR). But according to a "tech topic" recently posted on the Fiber Optic Association's Web site (www.thefoa.org), the smartphone in your pocket can act as a fiber-optic tester, in a pinch and for certain functions.

Chris Hillyer of the Northern California Sound & Communication JATC provided the tip to the FOA. According to Hillyer, "Your cell phone camera's image sensor can read IR [infrared] light. It uses this technology to help take pictures at night. In the advanced audio and CCTV field they have been using the smartphone camera to troubleshoot problems in IR communications."

He further explained that the human eye cannot see the IR light emitted by a remote control, for example. When such a device did not work correctly, we'd have to assume that either the batteries had worn out, or the remote's IR transmitter or receiver did not work properly. Now, he points out, you can use the camera on your smartphone to see the IR light emitted by the transmitter. To do so, follow these steps.

- Turn on your phone's camera function.

- Point it to the remote control.

- Push any button on the remote control.

- The IR light will show on the camera's screen.

Great - it works on a remote control. How does that relate to fiber-optic testing? Hillyer further explains: "You follow the same principles. Let's say you wanted to see if a fiber port was energized. You can either use the card that is supposed to show you in a few seconds whether or not the port is hot. Or, you could plug in your power meter, which you either may not have handy or you may not be able to find its card. Just pull out your smartphone, turn on the camera, and hold it over the port. If it is hot you will see a bluish white dot in the fiber bulkhead."

Hillyer says he found his camera phone to be very sensitive at 850 nm, but less so at 1300 nm (like all semiconductor detectors, he points out). "Our phone could still see 1300-nm sources at around -20 dBm, making it very useful even for LED sources, and of course, perfect for lasers," he concluded.

Copper cabling system has interchangeable modular connectorsThe VarioKeystone system from Leoni's infrastructure and datacom business unit allows for interchangeable modular connectors ranging from Category 6 to Category 7 (Class E through Class F).

With the VarioKeystone system, the user installs a fully shielded cable and, using a wire manager, terminates the cable to a contact block. The contact block can then accept the various connector interfaces, including RJ45 style and 4K7 (Tera) style interfaces.

Thomas Opfermann, product manager for copper systems with Leoni, says, "A cabling system allowing upgrades and migrations to be performed in a short time without costly reinstallation is becoming more and more important." Of the system's particulars, he explains, "An unlocking tool allows the jack modules to be separated from the cable plug quickly and effortlessly, via leverage, and replaced." The company says this attribute is particularly valuable in data centers, where upgrades can be made with little or no downtime.

The entire product line also includes a link extender that allows existing systems to extend up to 90 meters, as well as ready-made trunks, modular patch panels, wall outlets, floorboxes and consolidation-point housings.

A pictorially illustrated installation instruction for the VarioKeystone system is available at http://bit.ly/c1aZ4t.

WiFi interference myths tackledA white paper from Cisco Systems takes aim at 20 myths about interference in 802.11-based wireless LAN systems. The paper, entitled "20 Myths of WiFi Interference: Dispel Myths to Gain High-Performing and Reliable Wireless," addresses some of the issues that Fluke Networks' Carolyn Carter covers in the article in the article that begins on page 27 of this month's issue. Cisco's paper and Carter's article touch on the following.

- Interference can come from more than just other 802.11 networks

- Pre-deployment RF sweeps detect interference sources

- Interference's impact on a wireless LAN can be significant

Cisco's paper tackles several other issues as well, in a format that briefly states the commonly held myth then goes into detail refuting it. Among the myths addressed in the paper:

- My network seems to be working, so interference must not be a problem.

- I can overcome interference by having a high density of access points.

- There is no interference at 5 GHz.

- Interference is not a security risk.

The white paper, as well as Carter's article in this month's issue, impress upon the reader that RF analysis tools are necessary for complete interference detection.

Download the white paper directly from Cisco Systems at http://bit.ly/bzPcG5.

Cable crimper goes easy on the handsThe redesigned Sta-Kon Comfort Grip cable crimper from Thomas & Betts (www.tnb.com) requires 25 percent less handle force to complete a crimp than earlier versions. T&B says the new version requires as much as 75 percent less handle force than similar tools on the market. The redesigned cable crimper also includes ergonomic features including overmolded handles that naturally place the hands in a safe, strain-reducing position. A new feature, the Crimp-Assist foot, stabilizes the tool when it is placed on a work surface for additional leverage when crimping large connectors.

The crimper's Shure-Stake mechanism ensures a crimp cycle is completed before it releases to the open position.

The Sta-Kon line of tools is UL-listed for use with Sta-Kon connectors, T&B says, adding that similar tools in the line are available for terminals, flags, ferrules and disconnects ranging from 6 to 22 AWG with both insulated and non-insulated jackets.

Researcher: Megapixel network cameras to overtake marketMegapixel network cameras will account for more than half of all network cameras shipped by 2014, according to a new research report published by IMS Research (www.imsresearch.com). The report, entitled "The World Market for CCTV and Video Surveillance Equipment - 2010 Edition," also says that by 2014 worldwide shipments of HD and megapixel network security cameras will outnumber sales of HDcctv cameras 6 to 1.

When announcing the report's availability, IMS acknowledged recent developments of the HDcctv Alliance (www.highdefcctv.org) and commented on the influence it could have on the market's future. IMS stated, "Whilst a high proportion of new, enterprise-class projects are implementing network security, existing video surveillance installations, which are predominantly analog, still represent a majority of the installed base. It is this sector of the market which will be the most interesting in the coming years; will customers reuse their existing analog infrastructure and invest in HDcctv, transition to network cameras, or adopt a hybrid system? There appears to be little disagreement between protagonists of high-definition video surveillance that video surveillance systems are transitioning from analog video to networked systems. However, there is discord regarding the system topology needed to achieve this. For customers looking to capture high-definition and megapixel video, this can be done using a pure network video solution or by using an HDcctv analog video surveillance solution that brings the data onto the network using an Ethernet-enabled DVR."

Report author and video surveillance research analyst Gary Wong said, "HDcctv cameras will not impact the uptake of IP cameras in the short term. Many large and well-known vendors of video surveillance equipment have already invested heavily in developing and marketing network security cameras. It is unlikely that these vendors will adjust their technology roadmaps and marketing messages to accommodate HDcctv products into their product portfolios in the near future.

"HDcctv may gain traction in the low and middle segments of the market," he continued. "These market segments are serviced by small, local and regional security systems installers who have generally been slow to embrace network security cameras. HDcctv allows installers to offer the benefits of HD to their customers without having to operate outside of their technical comfort zone."

OneReach system extends Power over Ethernet distancesThe OneReach system, now available from Berk-Tek's (www.berktek.com) major distribution channels, is an integrated power and data cable solution for extended distances of Power over Ethernet (PoE) powered devices beyond the conventional 100-meter PoE limit. Berk-Tek says the OneReach system can extend PoE distances up to 3,850 feet.

The system comprises three components: a power injector module, the OneReach cable assembly, and the remote PoE port. The power injector module, located in the telecommunications room (TR), injects both the power and the data from active networking equipment such as fiber switches and a power-supply unit. This module is available in one- and four-port versions, and supports up to 24 devices in a rack-mountable 4U powered patch panel.

The OneReach cable assembly attaches to the power injector module through LC connectors for fiber, and through screw terminals for the copper/power conductors. The assembly consists of a Berk-Tek CL3R-OF-rated composite copper/fiber cable, under one jacket, which includes 12-AWG or 18-AWG stranded conductors coupled with either tight-buffered or loose-tube optical fibers. The cable assembly is built to specific lengths and is pretested and preterminated with M8 connectors for the remote PoE port.

The remote PoE port is a passive media converter that converts the cable assembly to an RJ-45, IEEE 802.3af-compliant output. From the RPP an additional 100 meters of twisted-pair cable can increase the distance out to the device.

"The OneReach system was designed to support single or multiple remote PoE devices, when the powered device needs to be more than 100 meters from the TR," states Mike Connaughton, RCDD, fiber optic products business manager at Berk-Tek. "Additional benefits include a lower cost and better ROI compared to installing power at the device end or pulling separate cables in separate pathways, while also providing network advantages such as remote management capabilities, consolidated UPS, and single-point troubleshooting."