Be proactive in your fiber inspection and cleaning processes

Remember that new connectors and test equipment require care.

By Brian Teague, Sticklers Fiber Optic Cleaners and

Tyler Vander Ploeg, VIAVI Solutions

Continuing with the informative series on the importance of inspection and cleaning processes to protect the optical signal, Sticklers Fiber Optic Cleaners and VIAVI Solutions discuss how being proactive in your methods is critical to the successful performance of a network.

Contamination is the number-one enemy of fiber-optic connectors. Dirty endfaces can be costly, slowing data speeds and in worst cases, bringing fiber networks down. This fact is well-known; however, many installers do not proactively implement “Inspect Before You Connect” (IBYC) procedures.

For detail on IBYC, see the first article in this series, “Fiber cleaning and inspection: Inspect before you connect,” June 2018, page 5.

Wear debris is the main culprit of dust-based contamination.

Reactive vs. proactive

A mistake made by many is using inspection and cleaning as a troubleshooting process when networks are not running as they should. However, by this stage the damage is already done—contamination has already affected your connectivity. Being proactive and implementing IBYC is essential to keep contamination under control.

Contamination can present in two ways, the first being residue-based. This can include fingerprint oils, moisture, the use of isopropyl alcohol (IPA) and even out-gassed plasticizers from protective dust caps. If not cleaned correctly, this can change the index of refraction. If the index of refraction within the fiber changes, it will strip some of the wavelength off and weaken the signal. In the worst cases, it can change the refractive angle enough that the signal is lost completely.

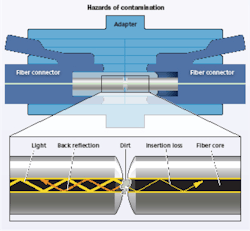

The second form of contamination is dust (or dirt). Although microscopic, it can create insertion loss and back reflection, impacting the reliability of a network. Dust-based contamination originates from many sources, however connector “wear debris” is the primary cause. This debris is produced by contact friction when the fiber connectors are mated, and creates an air gap between endfaces resulting in back reflection, signal attenuation and instability in the laser system.

If cleaning reactively, embedded defects can cause permanent damage to the fiber, with scratching and pitting commonplace. Sadly, the only way to resolve this is the replacement of the fiber and connectors.

Be proactive and use the IBYC process every time you connect. If the job is done right the first time it will prevent costly repairs and connectivity failure.

Residue-based contamination can change the fiber’s index of refraction.

New doesn’t mean clean

This brings us to the subject of new cable assemblies. It is a common error to assume they will have a pristine connector endface, which is contamination-free as it is “straight out of the bag.” But think again. Plastic endcaps used on new fiber contain chemicals called plasticizers. The plasticizers can outgas, leaving a film of small oil droplets on the endface. Many manufacturers also use mold release agents to speed the manufacturing process of the endcaps. These may retain some mold release agent on the inner surface, which can migrate onto the connector endface. To compound the problem further, there is the chance of wear debris contamination generated from putting the end cap on and taking it off.

The best practice to ensure optical connectors are delivering the designed performance is to always inspect and clean both ends of the connector pair before mating. Failure to remove debris from the two ends will cause cross-contamination of the ferrule endfaces disrupting the optical signal path.

When debris gets between mated fiber connectors, it creates an air gap between endfaces, resulting in backreflection, signal attenuation and instability in the laser system.

Don’t forget your test equipment

An important point here is not to forget to inspect and clean all test equipment. This process is frequently overlooked, but is essential. Connectors and ports on test equipment are mated regularly and are highly likely to becomecontaminated.

Fiber test reference cords (FTRC) use high-performance fiber connectors that have optimized characteristics to produce nearly zero loss when connected. If the IBYC step is missed, the results will be incorrect. You also run the risk of permanently damaging the equipment.

TRCs and patch cords are easy to access and view compared to the fiber inside the bulkhead, which is often overlooked. The bulkhead side may only be half of the connection, but it is far more likely to be problematic. Take care to IBYC all equipment to stop cross-contamination and ensure testing is accurate.

Sticklers Fiber Optic Cleaners and VIAVI will offer further advice on fiber inspection and cleaning in the next column. We will look at electrostatic charge and how it is the main factor for attracting dust in fiber-optic networks, and what every technician should have in their toolbox to clean effectively. u

Having more than 20 years of industry experience with fiber-optic connectors and cable assemblies, Brian Teague is product manager for Sticklers Fiber Optic Cleaners by MicroCare Corp., a manufacturer of products for precision cleaning, coating and lubrication. Brian provides technical support for the Sticklers line, which includes developing training programs on fiber-optic inspection and cleaning.

Tyler Vander Ploeg is the fiber solutions marketing manager at VIAVI Solutions, a provider of network test, monitoring and assurance solutions to communications service providers, enterprises and their ecosystems. His 17 years of experience in the fiber-optic industry include managing and developing new fiber-optic connectivity and test products, developing targeted marketing programs, authoring white papers and conducting educational training in fiber connectivity and test. The IBYC video series can be found on VIAVI Solutions’ website.