Conduit and innerduct increase cable system capacity

Barbara E. Thompson

In outside-plant installations, conduit is typically installed underground to protect cables from damage and to facilitate cable placement for immediate and future needs. You can also install conduit inside buildings to facilitate pulling cable between two points such as from the telecommunications closet (TC) to work-area outlets, or from an equipment room to a TC. To protect, isolate, and identify the cables, innerduct--also known as subduct--may be installed inside existing larger-diameter conduit.

Conduit is defined as a rigid or flexible metal or nonmetallic raceway through which cables can be pulled. In addition, although conduit can be used to house many types of cable, the National Electrical Code (NEC) uses the term "optical fiber raceway" in Article 770 to describe conduit, or raceways, for optical-fiber cable. Several types of conduit are available, such as electrical metallic tubing (EMT), rigid metal conduit, PVC, fiberglass, and flexible conduit. For premises installations, how-ever, metal flexible conduit is not recommended because of potential abrasion damage to the cable jacketing.

Metal conduit, which typically comes in 10-foot lengths, is fairly rigid and requires special tooling and accessories to join it. Nonmetallic conduit is available on reels in longer, continuous lengths that do not have to be joined as often.

"The only problem with installing EMT conduit is that it requires a special skill set and training, in addition to lots of practice--or you end up making swing sets," explains Kevin Smith, project manager at MTS Services (Bedford, NH). "Metal conduit comes in 10-foot lengths so you have to do any nonstandard bends by hand, and that`s where the technician`s special skill is necessary."

Arnco Corp. (Elyria, OH) sells innerduct to the cable-TV, telecommunications, and electric utility markets, says Tom Stewart, electrical products sales manager. "Inside a building, several types of duct are used--for example, riser- and plenum-rated--but all our products are manufactured from thermoplastic materials, such as polyvinylide fluoride [pvdf] and polyvinyl chloride [pvc]. The thermoplastic materials are easier to install than metal."

Where to use innerduct

There are three different types (or ratings) of innerduct: outdoor, riser-rated, and plenum-rated. Robert Jensen, engineering manager at Endot Industries Inc. (Rockaway, NJ), explains: "Outdoor is usually polyethylene and it`s not really rated. Then there`s a riser product, rated by Underwriters Laboratories [UL], which is generally a thermoplastic material such as polyethylene or PVC with fire-retardant chemicals added to it. And the third type of duct is UL plenum-rated, generally a pvdf product, which is fire-retardant and smoke-resistant," says Jensen.

According to Mike D`Errico, regional director of sales at Pyramid Industries (Erie, PA), most products that conduit and innerduct manufacturers make is for outside plant. Some manufacturers offer prelubricated innerduct and conduit, "very often incorporating some form of silicon," he says. "For premises cabling, Pyramid offers a plenum raceway (tested to UL-910) and a riser raceway (UL-1666) for installation in vertical shafts." In addition, the riser product is halogen-free and is often used for military, shipboard, or tunnel applications, depending upon the specifications.

Of course contractors install conduit where building codes require it, but also where the cabling system needs physical protection or protection from unauthorized access.

"We use conduit in riser and backbone systems from the building entrance to the main distribution frame," says Karl Clawson, senior vice president and partner, Clawson Communications (Greenwood, IN). "And we also install it for horizontal cabling, especially in university campuses. In the living quarters, we install cable in conduit because it gives the cable extra protection, and hopefully, keeps it out of students` reach," he says.

Some cabling contractors prefer to have other trades install conduit; for example, electricians who have more experience in performing this task. "Generally, the only time we use conduit is when we`re building a riser or penetrating a fire wall," says Smith. "Typically, we would not install conduit from the wiring closet to the workstation outlet. For short distances, as much as 100 feet, we would install conduit between buildings depending on the existing infrastructure.

Different features

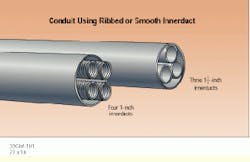

In addition to the traditional smooth-bore type, innerduct is available with a ribbed inner wall to reduce friction between the cable sheath and the innerduct wall. "A wave-rib on the inside of the duct reduces surface contact between the cable and the wall of the duct, thus reducing the coefficient of friction and allowing you to pull cable over longer distances," says Stewart.

Another variation is the multicelled conduit system, which offers outerducts with pre-installed innerducts. Clawson says that, because of its cost, his company does not use conduit with pre- installed innerduct. "We keep leftover conduit in stock to use on other jobs," he says. "But pre-installed conduit is a special application, so overages and underages are kind of costly to deal with."

For premises applications, Dura-line (Knoxville, TN) has designed a conduit, known as Hex-line, for multiple-duct applications between buildings. "As you pull the ducts off the reel (two to each reel), they go into a collector, which Dura-line supplies free of charge," says Ray McLeary, vice president of sales. "Each duct has a male and female part, which are snapped together, making a multiple duct system. This saves time, space, and money, but the most important savings is space." He explains: "Normally, you can put three 1-inch innerducts into a 4-inch conduit. With this system, you can fit four 11/4-inch or six 1-inch innerducts into the conduit."

When purchasing innerduct, you also need to be concerned with its tensile strength and crush resistance. "The thicker the wall material, the higher the tensile rating," says Stewart. "If you`re going to pull it over a long distance, select a wall thickness that allows you to pull the duct over that distance. The crush-resistance feature helps to ensure that the innerduct won`t be damaged during the placing process--or you can`t pull in the cable," he explains.

Because of the limited amount of tensile pull that you can exert on the cable, people look for ways to reduce the coefficient of friction inside the conduit. "There are products on the market such as prelubricated conduit," says Stewart. "And there`s even a different technology being used for placing cable, known as air-blown fiber (or ABF), where the fiber-optic cable is blown into the conduit. We manufacture what we call the `air-trak` system--a conduit system with chambers--for use in ABF installations." [Air-blown fiber is available in the United States from Sumitomo Electric Lightwave Corp. (Research Triangle Park, NC).]

Size and capacity

Conduit and innerduct have one thing in common: They facilitate pulling or replacing a cable for added capacity in a premises cabling system. However, every contractor knows that as an installation grows, the number of cables grows to fill all the space in the conduit. Therefore, choosing the correct trade size is important, because you must leave sufficient clearance between the walls of the conduit and other cables (see the eia/tia-569 standard). Typically, conduit trade sizes range from 1/2 to 6 inches in diameter. Minimum conduit size recommended for backbone cables is 4 inches. Sufficient clearance must be available to allow pulling the cable without excessive friction or bending.

The NEC conduit-fill tables define the amount (as a percentage) of different types of cable you can use inside a conduit. "The NEC typically covers power cables," says Stewart. "With high-voltage cables, you have to consider temperature and impedance, which really don`t apply in the case of data cables in conduit. The real question for data cable is: Can you pull it into the size of duct that you`ve selected?"

"The most important decision when installing conduit is the size of the conduit and clearance from the wall," says Clawson. For external use, we use 4-inch PVC conduit, and we try to install as much conduit in the trenches as we can for future use."

Innerduct partitions conduit

Cables are continually added to conduit systems that are often filled to capacity with generations of older cable. When new cables are added, friction and pulling tension can damage existing cables inside the conduit. One way to provide for future changes is to subdivide larger conduits with innerducts, which are smaller in diameter than conduit, generally nonmetallic, and semiflexible.

"In an existing structure, many installers do not want to pull new cable over the cable already in the conduit," says Stewart, "because they risk damaging the existing cable. To optimize a larger conduit, they`ll install several smaller innerducts inside it. They`ll pull a smaller fiber cable into one of the innerducts, and then have additional ducts to be used for future cable placement."

Innerducts are classified by outside diameter (OD) whereas trade-size conduits use inside diameter (ID). One-inch innerduct is generally used within buildings; however, 11/4-, 11/2-, and 2-inch innerducts are available for larger fiber cables. Although innerducts take up space within a conduit, they provide additional protection and flexibility in constantly changing cabling installations.

"Generally, if you`re installing a 4-inch conduit," says Smith, "you`ll end up putting in three 1-inch innerducts: one for fiber, one for data, and one spare. What you want to do is pull as much as you can at installation time."

Typically manufactured from thermoplastic materials, innerduct comes with a pull string already installed. It is available in ribbed-, corrugated-, and smooth-wall styles. Some types have prelubricated inside walls. These special coatings and the physical properties of the inner wall of the innerduct ensure less friction and tension when pulling cable.

"Corrugated innerduct is used in plenum and riser products," says D`Errico. "And, when manufactured from high-density polyethylene, it is typically used for short--1000 feet or less--installations." Smooth wall is used for direct-buried, trenching, plowing, aerial, and directional boring applications. "The premise behind ribbed conduit is that the cable jacket is "lifted" away from and has a smaller area of contact with the pipe, reducing the coefficient of friction. But the rule of thumb is: the larger the hole, the easier it`s going to be to pull the cable," he says.

According to Clawson, "We use ribbed innerduct if we`re pulling one innerduct, because it`s easier to handle. If we`re pulling through a directional boring machine and it`s a multiple pull, then we use smooth innerduct. It is easier to pull smooth innerduct on top of a smooth surface, and it doesn`t kink as easily as ribbed innerduct."

When using innerduct, it is important to verify whether it is a plenum or non-plenum area and to install the innerduct with the appropriate support. If the innerduct is secured with tie wraps in a plenum area, always use plenum-rated products.

Innerduct is usually offered in one color--orange for the fiber-optic communications industry. Color can sometimes be installation-specific; for example, one color for data cable, one for telephone, and so on. "There is a movement afoot to try to use color designations for various types of applications," says Stewart. "Orange is typically communications, red would be for electric power, and yellow for gas."

A low-smoke, low-flame-propagation innerduct, Plenum-gard from Carlon Telecom Systems (Cleveland, OH) is a flexible innerduct that can be used as a cable raceway in plenum areas.

A 4-inch conduit can typically house four 1-inch innerducts or three 11/4- inch innerducts.