Keep innerduct straight to ease cable pulling

Donald E. Larson, American Polywater Corp.

Problem

Anyone who has pulled innerduct knows how difficult it is to keep it straight. As it comes off the feeder reel, this continuous, flexible plastic duct--sometimes known as subduct--tends to snake because of reel memory, and it detours around or over obstacles.

It is difficult to pull fiber-optic cable through innerduct that snakes excessively, even when using cable-pulling lubricant. Field tests have shown that, as a rule of thumb, when there are more than 600 to 900 degrees of evenly distributed bends in a duct, pulling tension for the fiber cable will exceed 500 pounds, even with the friction reduction supplied by cable lubricant. This makes long cable pulls through innerduct difficult, if not impossible.

Solution

The primary factor in reducing pulling tension is keeping the duct straight. This requires thoughtful and careful placement.

Procedure

1) Directly plowing the duct into the ground is one installation technique. When plowing in the duct, pre-ripping the soil to prepare it for smoother plowing helps keep the line for the duct straight. Rocky terrain makes plowing difficult; you will not be able to pull as far in duct plowed in rocky terrain, even with the best plowing technique.

2) Trenching is another technique used to install duct. However, it is difficult to lay straight, continuous duct in a trench and then back-fill over it. Placing the duct under linear tension while it is being buried, and digging a "V"-shaped trench to hold it, can help keep the duct straight.

3) Perhaps the best way to install duct is to pull it through conduit. The inner diameter of the conduit limits the snaking of the innerduct, and there is also evidence that pulling the cable through the innerduct tends to straighten the innerduct when it is placed in conduit. However, too many innerducts pulled through the same conduit may inhibit this self-adjustment and ultimately add to tension in pulls.

4) When pulling innerduct through conduit, use cable-pulling lubricant to ease the pulling tension. Field trials have shown that lubricant allows you to pull four times further with the same pulling tension.

5) The lower the coefficient of friction (COF) of the cable-pulling lubricant, the less the pulling tension required for the same-length pull. A low COF is critical to multibend pulls, and even a small difference in COF can make a large difference in pulling tension. For example, in a test pull, a lubricant with a COF of 0.13 produced a pulling tension of 375 lbs, while a lubricant with a COF of 0.19 generated 967 lbs of pulling tension.

6) It is not possible to measure snaking during duct placement and then plan pulls based on these measurements. However, it is possible, using cable-pulling software, to take field pulling tensions and determine the effective COF from a field pull. This information can help optimize future pulls under similar conditions and can assist in choosing the best method of duct placement.

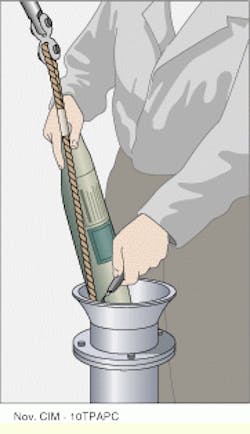

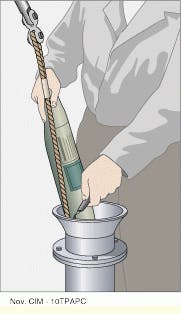

For short pulls, lubricant can be poured or pumped into the conduit. If the lubricant comes in packs that are attached to the pull rope, the proper procedure is to slit open the entire length of each pack with a sharp knife just as it enters the conduit.

Donald E. Larson is national sales manager for American Polywater Corp., Stillwater, MN. This installer tip is taken from his company`s technical newsletter, TeleTopics.