Clean gel off loose-tube fibers efficiently

Mitchell Cohen

Fibertron Corp.

Problem

Although the customer did not specify tight-buffered or loose-tube gel-filled fiber-optic cable for an outdoor application, you would rather use the former and stay away from the gel. However, you know that loose-tube cable is the correct long-term solution for the job. When you are working with loose-tube cable, it is difficult to clean off the fibers properly without getting the gel all over you.

Solution

With a little patience, you can clean loose-tube fibers and prepare them for splicing or a breakout kit if you use the proper tools. The following technique will eliminate any mess from the gel and, more important, clean the fibers.

Procedure

The necessary tools for working with loose-tube, gel-filled cable are: cable-jacket stripper, tape, wire or rotary stripper, lint-free cloths or wipes, shears, citrus-based solvent wipe and alcohol in dispenser or alcohol wipes. Two other tools that make the job easier are a seam ripper and disposable surgical gloves.

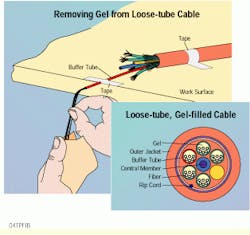

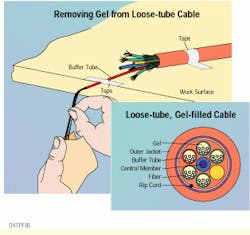

1) Using the cable-jacket stripper, remove the outer jacket of the cable. This tool should have a bidirectional blade, which lets you make a ring cut and a cut the length of the cable to split open and remove the outer jacket. (If the cable has a rip cord, you can use that instead.)

2) Attach the cable to a work surface with tape.

3) Cut the Kevlar and any wrapping material that surrounds the buffer tubes. Some cables also have a nylon braiding to hold the buffer tubes together. Because all of this material might be soaked in gel, it is recommended that you use a pair of disposable, surgical gloves to keep your hands clean.

4) Cut the nylon braiding with the seam ripper by carefully placing the tool between the buffer tubes and making cuts in the braiding along the length of the exposed fiber tubes.

5) Separate the tubes and wipe off any gel with a lint-free cloth.

6) Cut the central strength member to the desired length.

7) With a wire or rotary stripper, carefully cut into the tubes. A firm snap or bend of the tube exposes the fibers and gel. Then cut the tubes into 1-foot lengths.

8) Gently pull the tube away from the fibers with one hand, supporting the gel-covered fibers with a lint-free cloth in the other hand. This action removes most of the visible gel from the fibers and keeps the fibers aligned with the tube.

9) Use one-half sheet of a citrus-soaked solvent sheet to wipe down the fibers in the tube. Gently clean the fibers until they squeak.

10) Dry the fibers by wiping them with a clean, dry, lint-free cloth. Run a dry finger gently along each fiber and, if you can still feel some gel, use the other half of the wipe to reclean the fibers, and dry them again with a lint-free cloth.

11) When all the gel has been removed from the fibers, wipe them with an alcohol wipe to remove any gel residue. Again, clean the fibers until they squeak.

12) Finally, dry the fibers again with a clean, lint-free cloth. The fiber-optic cable is now ready for splicing or a breakout kit.

After removing the gel, dry the fibers with a clean, dry, lint-free cloth. The loose-tube, gel-filled cable is enlarged (inset) to show details.

Mitchell Cohen, Registered Communications Distribution Designer (RCDD), product manager of test equipment at Fibertron Corp., Fullerton, CA.