ColliSys favors design/build for backbone upgrades

To bring a large campus cabling project in on time and under budget, this Minneapolis contractor applied both innovative management and plain old common sense.

Arlyn S. Powell, Jr.

When ColliSys, an electrical contractor in Minneapolis, heard that nearby Hamline University was planning an upgrade to its campus backbone network, it seemed like an ideal project for the company`s specialized systems group, which focuses on low-voltage and optical-fiber cable installations.

Systems group manager Karen Mahn, registered communications distribution designer (rcdd), recalls that Hamline`s vice president of information services, John Smaby, hired an independent cabling consultant to establish the criteria for the project. "It was called a concept document," says Mahn, "and wasn`t as specific as a request-for-proposals. It didn`t, for instance, define what materials were to be used or what procedures followed."

Instead, the concept document focused on the results Hamline desired and what types of systems the university wanted for specific applications. This document, in turn, was used to develop the legal contract specifying the work to be done. ColliSys was the prime contractor; no general contractor or architectural firm was involved.

The Hamline project was also unusual in that it involved a negotiated contract rather than going to the lowest bidder. This fact, according to Mahn, benefited both the university and the contractor. "One of the exciting things for all of us," says Mahn, "is that we came in approximately 20% under budget. From the contractor`s viewpoint, I feel very firmly that the reason we came in under budget is that it was a design/build situation.

"ColliSys was able to influence the design of the project," she continues. "We had input on not only material choices but also on critical issues such as closet location and layout, cable pathways and routing choices. We held construction meetings, and when we hit the proverbial brick wall, we`d talk things through. On low-bid projects, that`s usually not an option for the contractor." Mahn can recall only a handful of projects in recent years that have been structured so that the contractor can provide knowledge and direction to the extent possible on the Hamline project.

If Hamline did not select ColliSys on the basis of low bid, then what criteria were used to select the contractor? Mahn believes there were several. "Recommendations from local vendors made us stand out," she says. A key recommendation came from CSP Inc., a Minneapolis-based fiber and copper assembly manufacturer and network hardware supplier that has provided Hamline University with networking products and support services for a number of years (see "CSP Aids ColliSys with Hamline Installation," page 27).

A second factor was ColliSys`s reputation among local electrical contractors. And a third was certainly Mahn and her field staff. "I`ve been in the business 10 years," she says, "and have done a significant amount of fiber optics." In fact, Mahn entered the industry a decade ago as a telephone installer. A member of the International Brotherhood of Electrical Workers, she says she has always been on the electrical contractor side of the business. In addition to taking classes at a local vocational technical school, Mahn received training at AT&T`s Hickory Ridge facility in Lisle, IL, for optical fiber, after which she worked as a fiber technician for two years. When she moved into the office, she advanced rapidly from project coordinator to project manager to her current position as division manager.

Meeting of minds

Before beginning the year-long installation, which was completed last October, ColliSys had a preliminary planning meeting with the client. "My group sat down with the customer and worked through the various needs, the different buildings, the timeframe, that sort of thing," she says. Thereafter, construction meetings were held every one to two weeks, depending on the phase of the project currently under way. These meetings were a major factor in the success of the installation and contributed to what Mahn calls "the comfort factor" by allowing all parties to bring issues to the table and resolve them on the spot. The meetings were attended by Hamline vice president John Smaby, his network manager Brian Johnson, physical plant manager Dennis Jordan, Mahn, and her foreman.

"We were able to hammer out all the issues that came up," she says, "because on a project this large, there are going to be problems. We found out, for instance, that some of the steam tunnels through which we wanted to route cables had collapsed, and others contained asbestos that had to be abated. These are problems that no one would have been able to foresee up front."

Because of the construction meetings, the normal procedure of submitting change orders was avoided. "We`d all put our heads together and come up with a plan," states Mahn, "and that really kept our work moving fast. We might say, for instance, `This isn`t going to work, but if we come in from the opposite end of this building, we could create an intermediate distribution frame over here. Do you have 70 square feet of space that we could use for a closet?` "

An added benefit of the regular meetings was that ordering from vendors could be better planned and coordinated. "That way vendors could supply their products in time," according to Mahn. "We never had to wait for product."

Planning and installing the campus backbone unearthed several challenges. The concept document called for interconnecting 17 university buildings, including classrooms, administrative offices and residential dormitories. The two cabling media used in the backbone were multimode optical fiber for data and half-inch, hard-line coaxial cable for video.

Why did Hamline select fiber over copper for its backbone network? "Confidentiality, of course, is an issue," says Mahn, "especially in today`s environment, because there are so many kids who can hack onto networks. Security problems could be solved by fiber, since it can`t be tapped.

"However, I think the real issue was that the network had become so large and fragmented that it had to be consolidated. And because of the distances between buildings, copper was not going to be an option; the logical solution was fiber optics."

The coaxial cable was called upon to carry both commercial cable-TV and the university`s own programming. "It was a true two-way, broadband system," says Mahn, "capable of carrying both commercial transmissions and local productions." ColliSys initially researched the possiblity of installing singlemode fiber for broadband, but abandoned the idea. "The electronics for singlemode fiber to carry video was just too expensive at the time to fit their budget," according to Mahn, "so we had to do it the standard way."

Backbone installation

One unusual feature of the backbone installation was that the two cabling media terminated at different points. The cable-TV company`s headend was in the basement of the library, while the centralized distribution frame for the data network was to be located at the heating and cooling plant. "We actually ended up heading cables from the same building in different directions," Mahn adds, "because all of the coax had to run to one building and all of the fiber to another."

The two networks were wired in a star topology, and the multimode fiber was specified in accordance with the tia/eia-568a standard. The details of backbone installation, however, presented some challenges. An existing network of steam tunnels was to be used for routing the backbone cables, but some directional boring and laying of new conduit paths were also required.

"It`s an old facility," Mahn says, "and some of the steam tunnels had been capped off. In other cases, there were closed or abandoned tunnels created by various construction projects of the university. So we had to do a lot of research to find routes into some of the facilities." In addition, some of the tunnels contained asbestos. The cabling crews either had to wear special protective clothing or wait until the asbestos had been abated.

Once tunnel routes were selected, ColliSys crews created their own cable-hanging system by shooting anchors into the ceilings of the tunnels. They then hung indoor/outdoor cable that was jacketed to resist the steam in the tunnels.

The need for directional boring was also an issue worthy of comment. Upgrading the campus backbone required tunneling under three streets. "Directional boring is always a surprise," says Mahn. "You`re never quite sure of the rock content and so forth. For example, we had to bore under Snelling Avenue, a main highway and an old, old street. We had to go down 24 feet before we could get across."

Mahn, with her optical-fiber background, feels that laying the fiber backbone was quite straightforward, but installing the coaxial cable was another matter altogether. "It was an easy install for the fiber," she says. "We could always maintain our minimum bend radius, even though sometimes we had to lay the cable in a circle when changing direction. The half-inch, hard-line coaxial cable can`t be kinked, however. In the tunnels we had to do some gentle bends using conduit pipe-benders. We also wound up doing some 90o fittings."

Since the campus backbone cabling was of indoor/outdoor construction, it had to comply with the National Electrical Code and be terminated within 50 feet of entering a building. "So we either had to put in a conduit run to get us to the main distribution frame," says Mahn, "or we had to do grounding and everything right at the point the cable entered the building and transfer over to indoor cable there."

ColliSys was also responsible for horizontal cabling within each university building. The concept document called for two strands of optical fiber to each eight workstations in the academic and administrative areas. Twelve-fiber backbone cables went from main distribution frames in each building to closets on each floor. From there, one Category 3 copper cable for voice and one Category 5 cable for data was run to each workstation in the horizontal runs, which were also configured using a star topology. The residential dormitories had slightly different requirements; since each dorm room housed two residents, two voice and two data lines, along with a single broadband line for video, were run to each room.

Challenging schedule

"It was a challenge to meet our very rigorous construction schedule," says Mahn, "especially since we had to minimize downtime because of occupied dorms. Privacy and security are always critical issues. Our workforce had to be careful to identify themselves before entering rooms. They also had to work around class schedules in academic buildings.

"We went into it thinking we were probably going to have to do some after-hours work, either early-morning or off-shift work," comments Mahn, "but, surprisingly, we were able to work through the scheduling problems. It worked out wonderfully for us, because nobody likes working at 2 AM."

Mahn credits the tight scheduling to ColliSys`s close relationship with the Hamline staff. "John Smaby and his staff did the legwork well ahead of us," she says. "We`d have meetings with the resident managers when we were going into the dorms, for instance, to let them know when we were going to be there, and what to expect. We were very sensitive to their issues, so I think that made them bend a little more for us."

Another challenge during the installation phase was what Mahn calls "the enormous variation of building construction." She explains, "The installation covered everything from beautiful, brand-new buildings to ones on the state historical register. In historical buildings, for instance, we had to be very careful of the woodwork, hiding wiring and otherwise creating wiring opportunities in buildings built before the telephone was invented."

Mahn feels it was a tremendous coordination challenge "just getting so many buildings up and operating," but she thinks her crews performed exceptionally well, and she is proud of the fact that her group supplied all of the labor except for the directional boring and excavation, which were subcontracted to specialists, and the conduit work, which had to be performed by licensed electricians from ColliSys.

How did the project go from the standpoint of the client? With the installation work going smoothly, the project completed on time, and the budget not exceeded, it`s no surprise that Mahn feels it went well. "They`re very happy," she says, "and it`s turning into a very good maintenance account for us, which is always nice for the contractor." Hamline is expecting to install a new telephone switch this year at its centralized distribution frame, and ColliSys is working closely with Hamline to help resolve any construction questions.

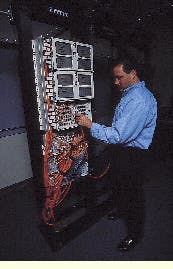

Fred Thomson, product manager at Computer System Products Inc. (CSP), makes an additional connection from Hamline University`s campuswide fiber-optic backbone to its Ethernet switch. CSP provided the fiber-optic products and the network hardware.

Hamline University, in Minneapolis, is situated on a picturesque campus, but its recent backbone cabling upgrade, connecting 17 buildings, had to pass under three streets, including a main route--Snelling Avenue.

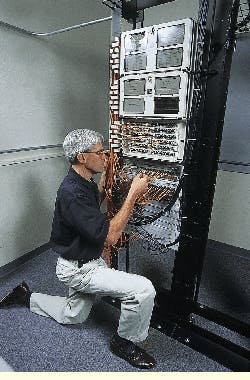

Kevin Pitkin, fiber-optic product manager at CSP, checks out one of Hamline University?s new distribution frames.

CSP Aids ColliSys with Hamline Installation

ColliSys systems group manager Karen Mahn credits local manufacturer Computer System Products Inc. (CSP--Minneapolis, MN) with influence in helping her company procure the Hamline University contract. "Before this project, ColliSys hadn`t worked with Hamline," she says, but CSP was a long-time supplier of networking equipment and services to the university.

CSP was spun off in 1982 from an electrical manufacturing company, Engineered Products Co. (epco), that made a single product--a grounding pigtail. Duncan Lee, who left the University of Minnesota in 1980 to run epco for his father, has built that single product into a three-company, $40 million concern. (In addition to CSP and epco, Lee recently launched Lee Communications Inc. to market computer cabling products to the retail market.)

Lee`s star performer, however, is CSP, the largest and fastest-growing of his enterprises. Sales have doubled in the last three years, topping $24 million in 1995 and projected to reach $30 million in 1996.

CSP`s success is due, in part, to being in the right place at the right time. The company has successfully tapped into the revenue growth of the cabling industry that has occurred as generic structured cabling supplants proprietary voice and data cabling.

The company`s future is being built on a newly introduced line of standard and custom fiber-optic cable assemblies. Lee expects CSP`s revenues to double over the next two to three years as the company assembles and markets multimode and singlemode fiber-optic cable assemblies, and components such as connectors, attenuators and splitters. The 62.5/125-micron multimode cable assemblies come in simplex and duplex formats and are terminated with half a dozen different connectors, including ST, SC, SMA, Escon and fddi. Standard lengths run from 4 to 25 feet. Each assembly is tested to fiber-optic test procedure (fotp) standards. Customized orders include fiber cut to length and spooled, and terminated with factory-installed connectors. Multimode fiber in duplex, premise distribution, breakout and aerial/outdoor formats is being stocked.

Lee attributes his companies` success to the people who work for him. "I get credit for hiring key people who came up with all the ideas that are making us a success," he says. "If I had to learn all the ins and outs of the technology in this fast-changing market, we would not be where we are today."

Kevin Pitkin, fiber-optic product manager at CSP, checks out one of Hamline University`s new distribution frames.