Multimode fiber cable appropriate for shorter-distance applications

Barbara E. Thompson

Many designers and installers are specifying multimode fiber-optic cable for premises wiring, local area networks or computer interconnections because, for shorter distances, multimode cable allows for low-cost connections. Singlemode fiber-optic cables, however, are still preferred for long-distance, high-speed applications.

"Typically, we`d use 62.5-micron multimode fiber for distances under 1.5 kilometers," says Amy Barnes Frey, president of Alpine Communications Consultants Inc. (Broomfield, CO). "You get just as high speed if you`re going short distances: more bang for your buck. I wouldn`t use singlemode for anything other than connecting buildings where there might be a distance limitation."

Multimode fiber allows many rays of light (modes) to propagate through the fiber at one time. Typical core/cladding sizes (measured in microns) for multimode fiber-optic cable are 50/125, 62.5/125 and 100/140. The 50/125-micron cable, which costs less than 62.5/125-micron cable, is often used for video distribution and moderate-distance, non-networking applications. Of the three sizes, 100/140-micron multimode fiber-optic cable costs the most; however, it captures more light from inexpensive light sources and is appropriate for shorter-distance applications.

Cable design Installers and designers must also consider the environment where the cable is to be installed. Some types of cable cannot be placed inside air-conditioning or ventilation ducts because a fire inside these ducts could cause the outer jacket to burn and produce toxic gases. A critical factor in selecting cable, therefore, is its required fire rating.

The 1993 National Electrical Code states that "optical fiber cables in a building shall be listed as being suitable for the purpose and cables shall be marked in accordance with Table 770-50." Two common ratings for multimode fiber are OFNP (optical fiber nonconductive plenum) and OFNR (optical fiber nonconductive riser).

According to the NEC, nonconductive plenum cable is defined as "being suitable for use in ducts, plenums, and other space used for environmental air and shall also be listed as having adequate fire-resistant and low-smoke-producing characteristics."

For example, a plenum space can be above a suspended ceiling or below an access floor. A riser is the vertical pathway or space between floors.

Another decision installers must make is whether to use tight-buffered, loose-tube or ribbon cable.

In tight-buffered cable, each fiber is buffered by a protective thermoplastic coating to a diameter of 900 microns. Tight-buffering ensures that the fibers are in predictable positions, making it easier to install connectors. Tight-buffered cable was developed for indoor and outdoor premise-wiring applications.

In loose-tube cable, each coated fiber is installed in a loose helix so the fiber can move freely without touching the walls of the cable tube. Typically used for outside plant, the tube is filled with optical gel, which protects the fibers and also prevents water from entering the cable. Loose-tube cable is used for long-distance telephony applications, which require low-cost, high-fiber-count solutions.

"Loose-tube cable was developed early in fiber-optic cable history," says Allen Kasiewicz, president of Trellis Communications Corp. (Manchester, NH), "because the early fibers were very fragile and needed some packaging to isolate the fibers from the rigors of installation. From our perspective, loose-tube cable is great for outside applications, but for interior applications, we go with the tight-buffered cable."

In ribbon cable, 12 coated fibers are bonded together to form a ribbon (see "Composite cable promises benefits, raises questions," November 1994, page 6). Several ribbons can be packed into the same cable: More than 100 fibers can be put into a 0.5-inch square space with ribbon cables. Ribbon cable can be mass fusion-spliced or mass-terminated into array connectors.

"We have used ribbon successfully in a large-scale distribution," says Frey, "where we installed 3000 miles." However, Kasiewicz says "The termination procedures are difficult and very precise. Our runs are short or we build connector-intensive networks, so it`s easier to terminate the tight-buffered cable."

Other considerations

For installers and designers, cable cost is an issue, as is availability. When customers decide they want to do the installation now, Kasiewicz explains, "It is critical to get cable quickly with the performance and specifications we`re looking for."

Both Frey and Kasiewicz said that strippability of the fiber sheathing is a very important factor. "It makes a difference as to who manufactures the coating," says Frey. "Some cables are easy to strip and some are not."

After the fiber goes through the extrusion process, if the plastic is very hot and the cooling water is very cold, what is known as "shrink-back" occurs. The sheathing shrinks back very hard, which makes it difficult to strip off the fiber. It can also induce microbend losses.

"What we demand from our cable supplier is detailed test documentation," says Kasiewicz, "not only power losses but also time domain reflectometry traces on the fibers." He recommends that, "You go to your cable manufacturer, take a look at the plant and see how the cable is made. It will give you a greater understanding of the issues."

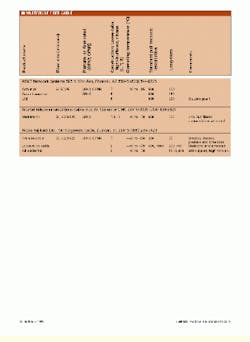

Plenum- and riser-rated tight-buffered cables are available from Siecor for 2- to 144-fiber horizontal cabling applications.

Your Views Are Important

Cabling Installation & Maintenance encourages readers to communicate with their peers. "To the Editor" provides a forum for co rrecting mistakes, stating opinions and discussing issues. Why not drop us a line?