Low-loss connectivity for multimode applications

Alternatives to field termination may gain popularity as high data rates drive down loss allowances.

As has been documented in this and other trade publications, the Institute of Electrical and Electronics Engineers (IEEE-www.ieee.org) specifications for 10-Gigabit Ethernet (10 GbE) transmission include several options for running the application over multimode fiber. A new breed of laser-optimized 50-µm multimode fiber has gained particular attention, because it is capable of carrying 10-GbE signals 300 meters (see "Laser-optimized multimode fiber an excellent choice for 10-Gigabit Ethernet," page x).

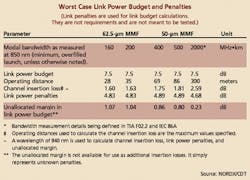

The IEEE specifications for 10-GbE also spell out attenuation, or signal loss, requirements for all transmission scenarios including multimode fiber. Some of the implications of these loss requirements are described in the white paper 10 Gbits/sec LAN Net work ing: Optical Fiber LAN Design Con siderations, authored by Richard Perron, product manager with NORDX/ CDT (www.nordx.com). NORDX/CDT is one of a number of vendors offering laser-optimized 50-µm multimode fiber. In the white paper, Perron says, "Since the 10-GbE fiber link budget is much tighter [than the budgets for other applications], the design options for 10-GbE are very limited with the traditional cable and field-installable connectors, which will generally meet the budget restrictions limiting the connections to two mated pairs."

Perron adds, "But for the numerous instances where real-life requirements (rapid implementation, disaster recovery, physical design limitations, redundancy paths, corporate management demands) demand an effective and efficient solution, we need alternatives."

Perron believes the low-loss allowances will prompt some users to choose factory-terminated rather than field-terminated connectors. "It eliminates the potential for variance of results than can result from field termination," Perron said in an interview. "We are already seeing this selection in some data centers and storage area networks, where link lengths are determined and preterminated solutions are a good fit."

Another possibility for optical-fiber installers is fusion splicing. Commonly regarded as a high-end (read: expensive) optical connectivity option, fusion splicing is also well known as an extremely low-loss connection method. "With a fusion splice, return loss is usually -60 dB or better, where it's -55 dB or so with connectors," says Donald Gross, manager of fusion-splicing applications engineering with Sumitomo Electric Lightwave (www.sumitomoelectric.com.com). "Also, any issues concerning tolerances between the ferrule and fiber are removed when you make a joint with a fusion splice."

"The cost-effectiveness of fusion splicing versus using connectors generally depends on the user," says Jeff Fullwood, product specialist for splice equipment with Corning Cable Systems (www.corningcablesystems.com). "Premises and campus cabling installers generally don't do pigtail splices," he says, "and perhaps they don't own a fusion splicer. On the public network side, local exchange carriers generally do not use field-installable connectors. They do use the fusion splicers."

"From a cost standpoint," Fullwood continues, "if you look at the toolkits plus consumables, raw materials, connector prices, there is a tradeoff between the two. The upfront cost of the splicer is significant, and pigtails have their cost as well. On the field-connector side, there is an installation kit [generally costing between $800 and $1,200], plus the connectors."

Another consideration, Fullwood says, is where the terminations are being made. For example, it makes more sense to fusion splice in a main crossconnect where dozens or even hundreds of connections are made, than it does to carry a fusion splicer from office to office making connections at the workstation.

These decisions are not just hypothetical, as Fullwood points out. "One customer of ours is opting for fusion splicing over field connectorization," he notes. "They are not running 10 Gbits/sec, but still cannot afford the loss associated with field connectors."

What are installers and users in for if and when they do opt for fusion splicing over field connectors? Many of them will be new to fusion splicing and will not necessarily know their way around the technology. Trey Hoffman, product manager for fusion splicers with Fitel Interconnect (www.fitel.com), offers these users some good news: "It's not necessary to buy a top-of-the-line core-alignment model for fusing multimode fiber. Clad alignment would suffice. Core alignment reduces the margin of error and offers flexibility for different fiber types [singlemode and multimode], but for premises and customer-owned outside-plant installations, clad alignment is perfectly appropriate."

Sumitomo's Gross concurs. "The core-alignment unit is not core alignment in the multimode selection," he says. "It uses diameter alignment, detecting the diameter edges and aligning them. With multimode splicing, the accuracy of core-aligning technology is not required.

That's not to say that nothing will be different when it comes to splicing the new laser-optimized 50-µm fiber. "There may have to be some optimization in the splicing program," Hoffman explains. "But it won't be a big deal. Some of the qualities in the glass may require a longer or shorter arc to ensure a proper melting point. Other fibers, in cluding LEAF and TrueWave, have required a slight modification in the splicing program. But arc properties would be the extent of the issues."

Gross explains, "The melting temperature of the fiber's cladding and its core can be different. If you're melting fiber too hot, too fast, it can cause a bubble because the core is not soft enough and traps air. Splicers have the ability to lengthen the duration or lower the power of the arc. Technicians have those options now; the flexibility is already in the unit."

Gross also points out that good workmanship is always critical for fusion splicing. "The cleave angle is critical with multimode splicing. Too steep a cleave angle also can cause a bubble in the splice."

Patrick McLaughlin is chief editor of Cabling Installation & Maintenance.

Field connect, fusion splice, or a little of both?

While installers and users may debate the merits of field connectorization versus fusion splicing, technology from Corning Cable Systems allows a little of both.

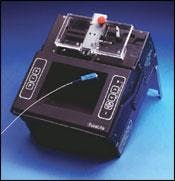

The FuseLite termination system is not a new technology; in fact, it's in its second generation. The FuseLite II splicer terminates optical fibers to prestubbed, factory-polished connectors. The splicer is used for this type of connection exclusively; it does not splice fiber-to-fiber.

The manufacturer describes the connector as a "near-zero-length pigtail." The product connects singlemode fibers only.

Jeff Fulwood, product specialist for splice equipment, says that the technology has become popular with some local exchange carriers because it relieves them of splicing pigtails.