Solutions and strategies for speeding MDU installations

By Kevin Morgan, Clearfield

After living through 2020, no one can deny the ultimate importance of using high-speed broadband to conduct everyday life. Work from home is now work from anywhere. Our daily commute has been reduced to a walk from the bedroom to another room in the house. With this change in lifestyle comes even greater demand on the broadband connections that serve as our umbilical cord to the world. Without it, business simply comes to a halt. So what are some ways in which service providers can provide the absolute best broadband connections in this work-from-anywhere world?

According to research from BroadbandNow, many apartment hunters said they’d be willing to pay more than $50 additional per month for a fiber connection. With a prediction that the U.S. will need nearly 4.6 million new multifamily units by 2030 and the current trend of remote working and learning, fiber deployment in this sector will rapidly increase and likely cause older complexes to upgrade current infrastructure to compete with new builds. So, let’s consider the best options for multi-dwelling units (MDUs).

Configuration of MDUs—MDUs come in many different shapes and sizes—single story, garden style (low-rise), two- and three-story apartments (mid-rise), and building with four or more levels (high-rise). Due to the nature of these buildings, when it comes to determining the best broadband connection, there is no one size that fits all. Until recently, multiple media types were legitimate considerations for making these connections: copper pair, coaxial, wireless, and fiber.

Which connection media works best—However, the demand for bandwidth has outpaced the broadband-carrying capacity of twisted-pair copper. Digital Subscriber Line (DSL) is no longer a valid consideration to provide even adequate bandwidth as many consumers are now finding out for themselves. Hybrid-fiber coax (HFC) cable continues to hold up well to the bandwidth demands. Where coax cable exists in-building, it serves consumers just fine—for now. Wireless technology has evolved rapidly as evidenced by the hype of 5G but we are still in the early stages for deployment. Without clever positioning of radios and antennas, the prospect of equipping MDUs purely with wireless connections is cumbersome and difficult to achieve. That leaves fiber.

Future bandwidth condiderations—Fiber-optic lines are futureproof and can stand up to the bandwidth demands now and into the future. Today’s Gigabit Passive Optical Network (GPON) architecture provides 2.5 Gbits/sec downstream and 1.25 Gbits/sec upstream shared across multiple subscribers. GPON provides consumers symmetrical gigabit speeds perfect for the work-from-anywhere world. Next-generation GPON improves this tenfold with 10-Gigabit Symmetric PON (XGS-PON) and is being deployed today on top of the existing GPON network already in place. Innovations like this show great promise for the longevity of fiber-based networks. International standards organizations are currently defining the next level of PON and are considering 25-Gbit/sec and 50-Gbit/sec architectures. The future of PON is bright.

Labor to build the network—The best part of the PON evolution for service providers is that the fiber networks built today can easily support the fiber architectures of the future. Labor rates are on the rise. Fewer skilled laborers with knowledge of fiber splicing exist. From a business-case perspective, it just makes sense to engineer, construct and build fiber networks right now using today’s labor rate as opposed to waiting years down the road to use future labor rates.

Plug and play—Innovative plug-and-play techniques exist in fiber-optic equipment these days that virtually eliminate the need for splicing fiber in the drop portion of the network. Fiber splicing may be required to connect the large-count feeder fiber coming from the central office or headend to the 144-count distribution fiber typically found in the wire center. But moving from the distribution fiber down to a single drop fiber can now be accomplished without the need for fiber splicing. This is especially true in MDUs.

MDUs typically have a wiring closet or room where all the communications equipment resides. Using a factory-tested, pre-connectorized fiber cable, installers can connect the entire MDU within the building and never have to splice a single connection. The only splicing required is the fiber entrance cable entering the wiring closet from outside of the building. From there, all that is needed to connect the rest of the building is to use connectorized cable. That’s it.

Operating the network (opex)—We’ve looked at the bandwidth-carrying capacity and impacts on labor. Now let’s consider the ongoing costs of operating the network (opex). Several factors impact the cost of operating the network and are distinctly different for active networks (power required) versus passive networks (power not required). HFC architectures operate using an active network, but all-fiber networks can operate in a passive mode (PON) by using the power of the laser typically extending 20 kilometers without the need for additional power elements. HFC has evolved to place fiber deeper into the network closer to the end-user, but still requires many elements for power including nodes, amplifiers, and cable modems. These devices depend on availability of commercial power as well as battery backup systems. In addition, these powered devices have difficulty holding up under extreme weather conditions and require protection, which adds not only to the cost of building the HFC but also to the ongoing opex to inspect and maintain these elements. Street-side cabinets equipped with battery strands are common in this HFC design and are vulnerable to the extreme effects of weather. That’s not to say that it’s impossible to accommodate these weather effects using well-designed equipment, but there is a price to pay.Recently, the Fiber Broadband Association “analyzed different components that contribute to opex and determined that truck rolls to address network problems and churn management are the main opex drivers, and all-fiber networks, due to a simpler, more-reliable, and higher-performance infrastructure, can save $54/year/home passed versus HFC, and $91/year/home passed versus DSL. Over a 10-year period the savings accumulate to $540 per home passed versus HFC and $910 per home passed versus DSL.” (“Operational Expenses for All-Fiber Networks are Far Lower Than for Other Access Networks,” Fiber Broadband Association, June 2020)

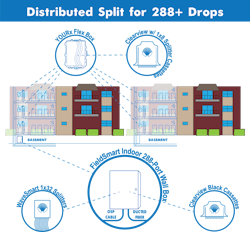

Compact design a must-have—One design element to consider when cabling up MDUs with fiber is that space is limited. Fortunately, fiber connectors have been getting smaller and smaller. In addition, advancements in bend-insensitive fiber allow tight spaces to be fully utilized within the MDU. Let’s compare the size of a typical outdoor fiber distribution hub (FDH) cabinet to the size of a metal wall-box with the same capacity to mount inside the wiring closet of the MDU. For an apples-to-apples comparison, let’s choose a 288-count size fiber termination element. The outdoor FDH cabinet takes up well over six cubic feet of space to mount on a pole, pedestal, or concrete pad. But the latest indoor 288-count wall-mount metal fiber delivery point on the market today measures to be just slightly over two cubic feet of space. That’s a huge space savings right where it’s needed.

One of the fiber-connectivity advancements that make these high-density connections possible is the multifiber push-on (MPO) connector. MPO fiber cables come in 12- and 24-count sizes. The ability to terminate up to 24 fibers using indoor-rated riser or plenum cables throughout the MDU makes perfect sense—especially when you want to minimize skilled labor and take advantage of plug-and-play.

The space constraints in MDUs dictate the need to use every bit of space available in connecting tenants in the building. Fortunately, the fiber connectivity options are plentiful and have kept pace with modern demands of network design. Fiber to the MDU makes economic sense because it is futureproof, easier to deploy with plug-and-play, less costly to operate, and compact enough to fit in the tightest spaces.

Kevin Morgan is chief marketing officer of Clearfield.