A decision maker’s guide to choosing splice-on connector installation

By Eric R. Pearson, Pearson Technologies Inc.

In the July/August issue of Cabling Installation & Maintenance, the article titled “Splice-on connectors gain ground in data centers” presented the advantages of fusion splice-on connectors (SOCs) in data centers. These 8 advantages are significant.

1. Simplicity

2. Ease of installation

3. Reduced difficulty in slack management (thanks to the ability to achieve exact cable lengths)

4. Minimum connector scrap

5. Minimizing operator error

6. Consistent low power loss

7. Ability to change connector type conveniently

8. Reduced patch cord inventory cost

In this article, I present a simple analysis to guide managers in the decision to choose SOC installation.

Labor is key

The key to this decision is labor utilization. The time required to field-install connectors exceeds the time required for the installation actions. In other words, labor utilization is always less than 100%. Utilization is the fraction of the total time required for installation actions. This fraction has two factors: time to perform the installation activity (put the connector on the cable) and time required in excess of the installation activity. In other words, utilization is:

(Time spent in installation activity)/(Time spent in installation activity + time spent in other actions)

The other actions include traveling to the installation site, setting up for installation, delays, and cleaning up after installation. During Pearson Technologies’ training programs in network design and costing (FiberPro™5 and BICSI FO110), trainees have proposed, as realistic, labor utilizations from 33% to 70%. Utilizations above 70% can be realistic when a large number of connectors are installed in a small number of locations. A 70% utilization would be appropriate for connector installation on multiple floors in a single building, as is the case in a data center.

A 33% utilization would be appropriate in three situations. One situation is a facility, in which the connector locations are limited access. In this situation, the installer needs to wait to get access to each location. Another situation is a facility, in which the connector locations are in different buildings or in widely separated locations. A third is a facility, in which a small number of connectors are installed in a large number of locations, e.g., fiber to the desk.

Determining actual, incurred labor cost requires increasing the hourly labor cost by the utilization. That is:

Actual labor cost incurred/hour = (labor cost/hour)/(utilization)

As an example, consider $55/hour as the total loaded labor cost for a technician. This cost includes the hourly rate paid the installer, payroll taxes, benefit costs, and profit margin for the contractor organization. Thus, if the effective time spent in connector installation is 50% of the total time required to perform the installation, a $55-per-hour labor cost results in $110 per hour actual cost. Similarly, if the labor utilization is 33%, the effective labor rate is $167 per hour.

Three general comparisons of cost factors are common knowledge: connector cost, installation rate/hour, and yield (number of acceptable/total number installed).

- Field-installed connector cost is less than that of SOC cost.

- Connectors installed per hour is lower for field-installed connectors than for SOCs.

- Yield is lower for field-installed connectors (95%) than for SOCs (~100%).

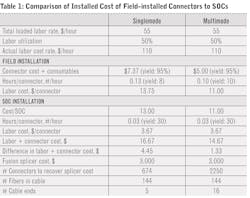

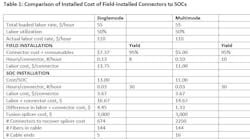

The table presents a prototype cost comparison for singlemode and multimode installation. It presents values that are approximate and typical. Other values apply in specific situations.

Actual connector cost for both field-installed and SOCs are above and below the values in the table. As shown in the table, the fusion splicer cost is roughly in the middle of the range of splicers available at the time of this writing. The cost of some splicers is in the range of $1,000 to $1,800, which range increases the advantage of SOC installation. In some situations, the cost comparison will be unfavorable to SOC choice or require such a high number of connectors that the manager cannot justify the choice of SOC.

The small number of cable ends implies that almost any professional fiber installation organization can justify using SOCs.Five more considerations

This article addresses the cost advantage. Other considerations can influence the choice of SOCs. One consideration is the clearance in the front of a rack-mounted enclosure. Some enclosures have limited space between the front panel and the door of the enclosure. As SOC boots can be longer and/or stiffer than those of field-installed connectors, the door may force the cable to violate its minimum bend radius. SOCs may not be suitable.

A second consideration is the length of fiber available for retermination. If the available fiber length is limited, SOC may be preferred even if the cost comparison is unfavorable.

A third consideration is the time available for installation. If the time is limited, multiple installation teams can be required. In this case, the cost analysis applies to each team.

A fourth consideration is provision of a backup splicer. If the manger chooses the SOC method exclusively, he or she requires a second splicer to be available in case of splicer malfunction. Without a backup splicer, the manager will be unable to provide installation service. An alternative to a backup splicer is splicer rental.

A fifth consideration is the time requirement for training personnel. SOC installation requires significantly training time less than field-installed connectors. One of the reasons for this reduction is the fact that the splicer examines the fibers and alerts the technician to defective fibers or positioning. The fusion splicer software makes it difficult for the technician to make mistakes. The result is reduced training time, reduced installation time, and increased yield (~100%).

The decision maker will use the specifics of the installation situation and an analysis similar to that in the table to determine whether or not SOC installation will provide reduced installation cost.

In conclusion, while the article in CI&M’s July/August issue focuses on data centers, the advantages of SOCs exist in many other situations. In this author’s opinion, most professional installation organizations will benefit from the preferred use of SOCs instead of field-polished connectors.

Eric R. Pearson is president of Pearson Technologies Inc. Pearson Technologies does not sell connectors, but provides training in the installation of both field-installed connectors and SOCs. Pearson Technologies has provided 32 years of fiber training and 41 years of consulting.