Cable labeling tools go heavy duty while lightening the load

By Patrick McLaughlin

In a document that encourages the proper use of labels in multiple cabling environments, Brady describes the value of an effective wire, cable and component marking system. The 32-page document, titled “Get Real Value from the Right Cable Labels,” can be downloaded from Brady’s website. The guide describes considerations to make when selecting cable labels and also “explains the variety of benefits of labeling, label durability and feature considerations, and the elements of a complete labeling system,” the company says. “It also provides visual examples of labels for wires, cables, components and facility identification,” Brady adds.

The guide includes six chapters: 1) The benefits of labeling; 2) Label durability; 3) Label considerations; 4) Identification options; 5) A complete labeling system; and a conclusion. Among the notable statistics in the guide is, “Only 25 percent of a tech’s service time is spent fixing the problem; the rest is spent searching for it.”

When Brady made the guide available right around the first of this year, the company’s regional product manager for product identification, Chris Gauthier, commented, “When it comes to installing, managing and updating hundreds to thousands of wires on a daily basis, the right labels can make a big difference. Not only do durable and professional-looking labels help to create an aesthetically flawless installation that you can be proud of, but they lead to increased efficiency, profitability and customer satisfaction. That’s because they provide the consistency you need to find just what you’re looking for and quickly complete the task at hand.”

The guide’s second chapter, addressing label durability, underscores the fact that some labels exist in less-than-friendly environments. “When considering a labeling system that aligns with your needs, keep in mind the various conditions that your wires, labels and components face on a daily basis,” the guide says. “Label materials and adhesives are made differently to stand up to a variety of challenges.” A durable label, it continues, typically includes a topcoat, substrate, adhesive and liner.

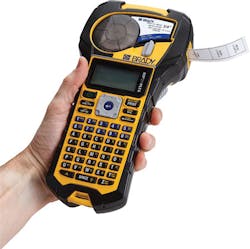

While some labels will have to survive in tough environments for the long term, the tools that produce those labels also must stand up to challenging environments-temporarily but repeatedly-when producing labels on-site. Brady’s BMP21-PLUS handheld label printer “combines a tough exterior with smart printing capabilities,” the company explains. The labeler’s shape was recently re-engineered to improve durability and ergonomic performance. Improvements included a center balance and ridges that assist gripping and handling, Brady notes. The BMP21-PLUS passed shock and vibration testing per MIL-STD-810G Method 5.16 S4.6.5, the company adds.

A range of innovations

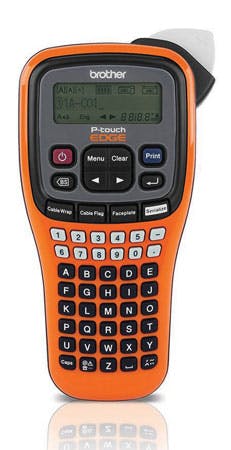

Other providers of labels and label makers have also innovated and updated their portfolios to achieve more-efficient label production, including in harsh environments. Brother Mobile Solutions’ P-Touch Edge PT-E550W wireless industrial handheld labeling tool is the company’s first industrial handheld product to feature WiFi connectivity to Windows, iOS, Mac and Android devices.

Brother explains that users of the PT-E550W can download and store custom label files and databases from select tablets, smartphones or PCs to print full project labels or individual labels wirelessly and on-demand at the jobsite. It prints labels up to 24mm wide, including heat-shrink tubing, and includes a dual-blade auto-cutter to make label strips easy to peel. Brother says the tool was specifically engineered as an alternative to sheet label systems, and is appropriate for large infrastructure installations.

Duane Yamashita, senior product manager for Brother’s Edge industrial brand, commented about the label maker, “Building on the functionality of the PT-E500 model, our PT-E550W adds increased convenience and functionality at the job site. With built-in templates, files and databases instantly available via wireless connectivity, work crews can help save time, improve accuracy, and minimize keystrokes in generating clear, long-lasting labels for wires, cables, faceplates, patch cords and other components of an installation.”

The tool’s wireless connectivity “provides greater flexibility to handle changes on-site in real-time,” Brother notes. “Should changes be required, users can make the as-built changes directly to the database in the PT-E550W, or to the same database file used for preprinting the sheets in the office, and send the file to a computer, smartphone or tablet for printing at the site.”

More recently, Brother debuted the P-Touch Edge PT-P750WVP, which the company says “fills a common productivity gap by enabling quick, onsite labeling from an app that turns a mobile phone or tablet into a powerful label design and print solution.” Yamashita said, “The goal is to help system designers and their contractor/installer partners bridge the gap between the development location where the project is designed and the jobsite where actual installation is performed.” He added that the tool “was designed to align with common datacom, labeling configurations. This allows for ‘as-built’ documentation and professional labeling of all components-including wires, cables, patch panels, termination points, faceplates, racks, cabinets and more. Using built-in templates, installation crews can print industry standard labels right from their smart devices.”

Brother’s datacom industry specialist Craig Robinson added, “Following best practices in cabling system installation requires a high degree of precision-and the ability to make on-site, real-time labels or modifications to labels is key to project efficiency. This solution brings true mobile functionality to the jobsite at a price point that puts it within reach of every contractor.”

Efficiency on the jobsite

In late 2015 Dymo launched the XTL series of industrial labelers. The Dymo XTL 300 and Dymo XTL 500 label makers are “fully outfitted with an array of time-saving features, all designed to make complex labeling jobs simple,” the company said. Both offer lifelike on-screen print preview that “showcases exactly how labels will look when applied to cables, pipes, patch panels and more,” the company added. “Additionally, hundreds of preloaded label templates further simplify the often-complex industrial labeling process by saving time and helping to eliminate mistakes.”

The Dymo XTL 300 is built specifically for professionals in the datacom and electrical fields. The rechargeable tool has impact-resistant bumpers and a wipe-clean keypad that prints labels from one-quarter inch up to one inch, in a full range of UL-rated materials and colors, Dymo said. It features PC connectivity and Dymo ID software for importing Excel and other database files for entire label batches. The XTL 500 prints labels from one-quarter inch to two inches, including safety signage and heat-shrink tubes in a range of UL-rated materials and colors.

A recent new-product introduction from HellermannTyton addresses another in-the-field issue associated with label creation-tight spaces and portability. The TT130SMC has a small footprint that the company says “allows for highly efficient printing in applications in which space is tight or when portability is important. The smaller size and optional hard-shell carrying case make it easy to transport to job sites, especially useful for data center and solar-installation labeling,” HellermannTyton said.

The carrying case has room for two printers, cables and label stock. It also can hold a wireless router, though one is not included with the kit. “One- and two-printer kits are also available that include everything you need for efficient and convenient industrial printing,” the company added.

The TT130SMC accommodates label roll stock up to 2 inches wide. The printer includes an Ethernet port that allows the user to connect to an existing network or to a wireless router for wireless, portable printing. The company stated, “For ultimate efficiency and optimized workflow, users can network several TT130SMC printers and use HellermannTyton’s TagPrint Pro label-creating software or a free TagPrint Xpress mobile application to create a multiple-printer network.”

In the conclusion of its labeling guide, Brady comments, “Well-labeled wires, cables and components give you immediate insight into how an installation works and how it’s connected. That way you can perform repairs, installation updates and upgrades in a safer, more-secure way, with a reduced risk of human error. By finding the right label type and material, the right way to acquire labels and a software system when it’s needed to manage your network, your job becomes more efficient.”

Providers of labels and label-making equipment continue to innovate and improve their offerings for the benefit of installers, technicians, and users who work with labels.

Patrick McLaughlin is our chief editor.