Measure your cable route to save money

Jim Rawson, Compel Corp.

Problem

One of the biggest problems facing an installation contractor is the cable pull itself. When pulling to a telecommunications closet or computer room, technicians pull extra cable so that the run will reach the patch panel or block. This means that, typically, they can throw away 15 to 20 feet of cable per run. At Category 5 prices, that can amount to $500 for 100 runs.

Solution

If the installer plans the pull beforehand, one hour of planning time (at an estimated $50 an hour) can be substituted for that $500 worth of wasted cable ends. The planning process involves measuring the actual distance from one end of the cable run to the other, rather than guessing and then adding a safety margin to be discarded later.

Procedure

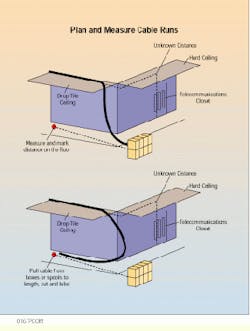

1) Look at your blueprints or cabling plan, and walk the route of the run. Note any obstacles that must be routed around or other factors that may affect the run length.

2) Decide on a way to measure the exact distance from your cable reels or boxes to the telecommunications closet or computer room, making sure to include the distance from the outside of the closet to the patch panel or block within. Ceiling and floor tiles of standard (and known) size can be counted, and the distance computed in that way. But perhaps the best method is to actually run a pullstring from the cable boxes or spools to the panel or block in the closet.

3) Make sure to include the length of any looped extra cable to be stored in the closet as well. The pullstring should follow the path of any wireway or other cable management device used in the closet.

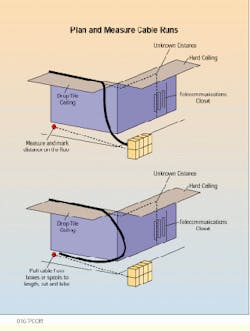

4) Retrieve the pullstring and lay it out in the corridor where the pull is being made. Pull the cables to match the length of the pullstring, and cut them. Leave minimal extra cable at each end of the pull--perhaps 2 feet per end.

Running a pullstring along the route of a cable pull can help you determine the exact length to which your horizontal cabling should be cut. Make sure to include the lengths of service loops at either end, the distance through any conduit to the wallplate and the distance along wireways in the closet to the termination point on the panel or block in the equipment rack.

Jim Rawson is in charge of safety and training at Compel Corp., Santa Fe Springs, CA