Fiber system built to handle MDUs' tight turns and corners

From the October 2012 Issue of Cabling Installation & Maintenance Magazine

The evolution of 900-μ bend-insensitive optical fiber led to a game-changing solution that makes fiber-to-the-home deployment in multi-dwelling units fast, easy and low-cost.

By Linnea M. Wilkes, 3M Communications Markets and Dean J. Yamasaki, Prysmian Group

Deployment of optical fiber-based services to residential consumers continues to grow worldwide. In North America alone, the total number of homes with all-fiber connections has surpassed 8 million, according to the latest figures released by the Fiber-to-the-Home Council Americas. A growing number of these subscribers reside in multi-dwelling units (MDUs) in urban areas.

Given population density and economies of scale, the MDU housing category has long been identified as an important growth opportunity for communications services providers. Even so, a large number of MDU residents remain unconnected to high-speed broadband services. Two big barriers have stood in the way of providing fiber-based services to individual living units with MDUs-structural obstacles and visual aesthetics.

Until recently, 900-μ tight-buffered optical fiber was considered a subcomponent of finished cables. Any number of standard and specialty-performance optical fibers may be tight buffered. The specialty fiber of specific interest to MDU applications is "bend-insensitive fiber" (BIF). Historically, this BIF was used alone in short lengths for electronics applications such as short coils inside metal housings with electronic components, and never used in long lengths for applications such as in fiber-to-the-home deployment.

But today, 900-μ tight-buffered, BIF is one of the key elements of an innovative full-fiber MDU broadband solution. Deploying fiber-to-the-home to MDUs is now much more economically attractive for servicers thanks to the development and availability of a BIF-based system.

Deployment challenges

Increased engineering, longer installation times and typically higher costs associated with fiber deployment in MDUs (especially older, existing buildings) have slowed the ability of service providers to fully realize the financial promise of the MDU housing category. No two MDUs are alike and no single solution fits all situations.

When routing fiber from a distribution hub to an individual living unit within an MDU, common architectural features create the need to bend the optical fiber around corners. Routing fiber around these obstacles deviates from a "straight run." Installing fiber in existing buildings often requires 10 or more tight bends to complete a service connection. Standard singlemode cable is not an option. A standard singlemode optical fiber is susceptible to induced macro-bend attenuation when bend radii are below 25 mm and can present system-reliability issues.

Building owners and homeowners associations (HOAs) have been barriers too. They have been hesitant to approve installations of apparatus and cable that, because of aesthetic issues, might permanently reduce the value of their properties and residential units. They want equipment and cabling needed to support high-speed broadband services hidden.

Additionally, building owners and HOAs also want to avoid complaints from residents during installation. So it is important to keep construction noise and related disruptions to a minimum.

BIF evolves to meet MDU demands

Many MDU drop-cable deployments in existing buildings used standard cabling products that are either stapled in place, routed through large, rigid moldings, or pulled through segmented, preinstalled latch duct raceways. All three of these legacy methods required improved bend-insensitive optical fibers to prevent macro bends and attenuation caused when cable is pulled through multiple bends or bends that violate a cable's minimum bend radius.

The first bend-insensitive optical fiber cable was introduced in 2002. It was capable of a 10-mm bend radius without significantly affecting signal performance. Since then, international performance standards have been published and several improved designs have become available. Improving upon the first-generation bendable fiber, manufacturers developed fiber with an allowable bend radius of 7.5 mm and now even as small as 5 mm. The most obvious performance advance of BIF over its standard singlemode predecessor relates to the reduction of induced optical signal attenuation when placed in small radius bends-a crucial factor in MDU deployment.

Installations within an MDU often require optical drop cable to be routed in congested areas involving multiple, tight-radius, 90-degree bends. Cable routing in confined areas, such as attics and crawlspaces, presents situations that could create localized tension when a cable snags on an obstacle. Such conditions create cable bends that may result in elevated signal attenuation that could be extremely detrimental to overall system performance. These bends are often difficult to find post-installation, and eliminating the performance issue takes time and can be costly.

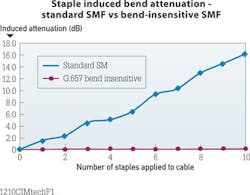

A properly selected bend-insensitive fiber, on the other hand, is designed to operate in small bend radii-as small as 5 mm. This product attribute provides consistent performance excellence over its service lifetime. The difference in performance between standard singlemode fiber and an International Telecommunication Union (ITU) G.657.B-compliant bend-insensitive singlemode fiber is illustrated in the figure above, using an attenuation-performance comparison of 2, 2.9-mm single-fiber cables manufactured with each fiber type.

The attenuation-performance superiority of the BIF is clearly demonstrated when compared to standard singlemode fiber. The performance improvement is the result of design engineering. The BIF's more-complex index of refraction profile prevents induced macro-bend attenuation created by point defects (staples) as well as sweeping alteration from a straight path (routing bends).

Innovations in horizontal cabling

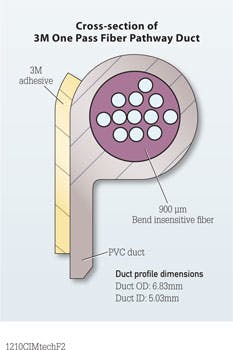

In 2009, an adhesive-backed fiber pathway for MDU hallways was introduced for horizontal distribution of fiber-optic cable. Constructed from an extruded PVC duct, the pathway is factory-filled with up to 12, 900-μ tight-buffered, bend-insensitive fibers (ITU G.657.B2-compliant) and laminated with a proprietary adhesive to adhere it to the surface of a wall.

The system is small, flexible, has no visible seams, can be painted, and is shipped on a spool. With the use of special hand tools, the system can be installed directly on a wall surface, eliminating the need for the installation of additional raceways, conduits or microducts. This installation method also minimizes the use of ladders, and the adhesive bonding mechanism makes for a neat and quiet installation compared to other system-installation methods.

Designed to be deployed in the hallways of existing MDUs serviced by fiber-to-the-home networks, the pathway can be made smaller than traditional optical-cable pathway solutions because it uses bend-insensitive 900-μ fiber as the medium to distribute fiber-optic services. Similarly, slack-storage boxes and other hardware and accessories are smaller than those that house multiple 2-, 3- or 5-mm outside-diameter jacketed cables. These space savings make the system more discreet and less conspicuous than conventional solutions.

Furthermore, because the fibers contained within the duct are factory-installed, installation of the cable pathway and drop cables can be completed in a single step. This quick installation process can save service providers as much as 35 percent in installation costs on each floor in which the system is installed, when compared to traditional raceway or crown-molding installation methods.

How it's different

Duct, raceways and conduits are typically sold without fiber, and are designed for use with jacketed cable. Jacketed cables typically contain buffered fiber but are not typically designed for fibers to be pulled through them. They also are not designed for surface-mounting using adhesives.

The relatively new BIF-based system serves as a carrier for tight-buffered fibers that are loosely filled in the pathway in advance at a manufacturing facility. Unlike conventional cable, the fiber pathway does not require further containment.

In spite of being flexible, seamless, and delivered on spools, the fiber pathways that carry the brand name One Pass are not considered to be cables. The One Pass has been listed to the requirements of UL5C, Surface Raceways and Fittings for Use with Data, Signal and Control Circuits for General Purpose applications only. Its adhesive-based design is intended for use in visible spaces such as hallways, and is not for classification as a riser or plenum-rated cable.

On the other hand, it cannot be considered a raceway. Raceways have a separate base and cover, are rigid, and are made in sections that must be cut to length during installation. Another important differentiator is that raceways are not prefitted with fiber or cable.

When viewed in cross section, the fiber pathway is not symmetrical about the neutral axis due to the flange and adhesive portions. Therefore, specific corner radius control hardware exists to ensure the proper bend radius and free movement of the fibers within the fiber pathway in all bending directions.

Within a given section of the pathway, individual preinstalled fibers can be pulled from a window-cut opening to a point-of-entry box for termination and prepositioning outside a living unit.

In short, this type of pathway system combines the positive attributes of more traditional horizontal cabling solutions into one package.

Fitting MDUs' needs

Deploying fiber in MDUs, particularly in older buildings, presents special challenges. Traditional horizontal optical cabling solutions are costly, time-consuming to install, and often unattractive to building owners and residents. To reach more customers in a cost-effective way, service providers need new options.

The pathway system described in this article addresses many of these challenges. Because it uses bend-insensitive 900-μ fiber as the medium to distribute fiber-optic services, the pathway itself can be made smaller than traditional optical-cable pathway solutions designed to contain multiple 2-, 3- or 5-mm jacketed cables. This makes the system smaller, more discreet and less noticeable to tenants and homeowners.

Because the fibers are factory-installed, installations are completed in a single pass. Specially designed installation tools enable this quick installation. Adhesive, engineered for compatibility with a broad range of indoor wall surfaces, is used to mount the pathway to the wall, making installation less disruptive than traditional methods.

This type of non-traditional use of fiber optics has helped to advance continued innovation and ensure fast, cost-effective fiber-to-the-home deployment to MDUs going forward.

Linnea M. Wilkes is global MDU business development manager with 3M Communications Markets Division. Dean J. Yamasaki manages emerging application and technology projects for Prysmian Group Telecom Business. 3M and Prysmian manufacture the products that make up the One Pass system.