Redundant links safeguard industrial network

Fiber-optic backbone design creates a fail-safe network by specifying redundant cable paths and an efficient modular fiber-distribution system.

Carol Everett,

Ortronics Inc.

When mobile equipment accidentally pulled down an overhead network cable at Northwest Alloys in 1994, taking down the entire network, the company received a wake-up call to revamp its network cabling plant. "Luckily," notes Jon Estep, systems analyst and network administrator for Northwest Alloys Inc. (nwa--Addy, WA), "we restored most network func- tionality in three hours. But that incident really underscored the vulnerability of our single-backbone-cable network."

A dependable network is key to nwa`s day-to-day operations. The company produces magnesium ingots and ships them to other manufacturers to create such end-products as aluminum alloys, fluxing agents for steel, and cathodic protection anodes.

Product specifications require that nwa monitor the chemical composition of its magnesium closely--laboratory analysis is a key to its production. Once the composition has been determined, the sampling results are communicated to the refining and casting departments as feedback for further processing, as well as for input into a database. This database ensures that the metal meets customer specifications and facilitates continuous improvement to the refining process. Without quick access to this information, nwa would be unable to automate its production and shipping processes.

A main component of nwa`s factory-automation system is data networking, which is used in the company`s office as well as for data collection from process-control equipment--such information as run rates, times, and quantities of raw materials being used. Altogether, this information contributes significantly to the efficiency of nwa`s manufacturing facility.

Design changes

Nineteen ninety-four proved to be a pivotal year for the company`s network. Its baseband Ethernet system (10Base-5, thick Ethernet) had traffic bursts of up to 40% of its capacity, which meant the system was already experiencing significant congestion. Also, due to the nature of the industry and the company`s campus layout, network expansion was subject to physical constraints. The copper cable then in use imposed limits on the distance that data could be transmitted, and it was subject to electrical interference when cables were routed near electrical furnaces, welders, or cranes.

"In an industrial environment such as nwa, it is commonplace to have boom trucks, cranes, and mobile equipment moving material," states Joseph King, project installation manager for Interwest Telecom Services (Richland, WA). "As an installer, I have seen the aftermath of cables being ripped down from aerial poles on the outside of buildings and distribution equipment being pulled up on the inside. We learn from those accidents and reconfigure the network and its pathways to make it accident-proof, instead of accident-prone."

Fortunately, following the mobile equipment accident at nwa, the existing cable could be tacked down, reterminated, and reconnected; but the incident showed how vulnerable the single-path network design really was. That occurrence was the impetus for a new, fiber-based network design.

Relying on redundant links

nwa`s old backbone consisted of two baseband (10Base-5) segments. One segment of 170 meters (two sections) within a single building complex was connected by duplex optical fiber to another segment with three sections totaling 350 meters, which ran between multiple buildings on wood poles. To upgrade this backbone, nwa relied on thorough preplanning to facilitate long-term expansion and ensure maximum bandwidth capability. To accomplish these goals, it chose optical fiber. To protect itself from future damage to its network, the company also looked at topologies that would allow for alternate cable pathways.

Today, the nwa cabling plant bears no resemblance to its former configuration. "We designed our new cabling plant to have redundant links," Estep explains. "Fiber can go longer distances and has inherently higher bandwidth, which gives us the opportunity to lay out our plant with multiple paths. In addition, fiber is immune to electrical noise created by welders and diesel engines. Induced intermittent electrical noise of this sort can cause network equipment to go tilt like a pinball machine."

The installation called for placing 14 main backbone cables running out from the servers in the computer center. The new pathways and fiber-optic cables created a reliable backup scheme for the main cables. "If main cables running in one direction get severed, we could still run via other routes and send information in another direction," assures Estep.

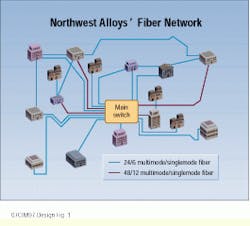

Forty-one cable runs were installed, using more than 38,000 feet of three primary types of composite cable: 18 runs of 24-multimode/6-singlemode totaling 21,980 feet; 19 runs of 6-fiber multimode breakout cable totaling 13,000 feet; and 4 runs of 48-multimode/12-singlemode totaling 3740 feet. Most of the new cables were installed along the exteriors of the industrial buildings and lashed to messenger cables between buildings and poles, to connect and crossconnect 35 different locations in 33 buildings. Although many existing wooden poles were used, nine others had to be erected.

nwa selected a Fiber Distributed Data Interface (fddi) network, the first local area network designed from the ground up to use fiber optics. The old 10Base-5 network, which used a thick, rigid coaxial cable, permitted 100 stations to be installed over 500 meters for each network section. fddi allows up to 1000 stations over a 100-kilometer range. "fddi was very functional for our new environment and could give us both the redundancy, which fit into our plan, and enough bandwidth between switches to allow for several years of growth," Estep explains. "And with an fddi-trunk-loop topology, a primary path carries information in one direction while the secondary ring distributes it in the other direction. This redundancy lessens the likelihood of network failure."

The fddi network also boasts of another fail-safe feature. In a typical layout, each station is attached only to adjacent stations in the ring, so if one station or one link fails, the network is still functional with minimal downtime, and what downtime there is would be concentrated on that one point of failure. In the case of a cable break, data can be accepted on a primary link and transmitted on a secondary link.

The design also consists of 11 multiport fddi- and Ethernet-switching bridges, which are interconnected through fddi and full-duplex 10-Mbit/sec Ethernet using the fiber backbone. With 244 logical switched-Ethernet segments, these devices provide automatic rerouting and network topology changes, should any cable breakage occur.

Making the network work

In theory, this configuration is ideal for the industrial environment at nwa. In reality, though, the system`s long-term reliability and functionality depend on the efficiency of its servers and associated hardware, which route information from the fiber- optic backbone to workstations or the information center.

"In specifying the upgrade for this unique plant site, we had to be able to retrofit the copper system of the past with the fiber-optic backbone of the present for use in data networking today, and for voice and video in the future," says Chris Wood of Graybar, the distributor who specified the cable- and wire-management systems. To accomplish this, Graybar worked with the installers, who relied on carefully preplanned positioning of distribution frames and patch panels. They chose a modular system that would best suit the installation layout.

Based on Wood`s recommendation and specification of products, nwa installed a variety of Ortronics (Pawcatuck, CT) fiber-distribution cabinets with patch panels, which range in size from 12 to 144 ports.

"Present and future network traffic loads dictated the variety and numbers of fiber ports at each location, which had to fit into existing spaces in each building," Wood explains. The design called for using ormmac fiber-distribution cabinets with patch panels from Ortronics. These panels were rack-mounted to crossconnect from bulkhead to bulkhead, or from bulkhead to equipment. The cabinets included two 96-port, ten 144-port, three 72-port, and seven 48-port snap-in panels. Nineteen 12-port fiber-distribution cabinets were wall-mounted in tight areas that were required to carry minimal data traffic. One semicustomized, 48-port, wall-mounted cabinet was installed in a tight area that could not accommodate a rack and had to be located 3700 feet from the nearest main crossconnect.

The cabinets, which accommodate multimode and singlemode patching and splicing, were preloaded with SC connectors for fast and cost-effective installation. The modular design of the panels permits unlimited fiber-capacity expansion.

The cabinets were also capable of integrating the new fiber backbone and the existing coaxial cable to the desk. Most of the previously installed cable to the desk consisted of 10Base-2 coaxial cable. Future bandwidth requirements and distance limitations will determine whether a new or replacement workstation will use fiber-to-the-desk. "The cabinets enhance the new network operations, while seamlessly integrating today`s hardware and technology with flexible options for emerging technologies and maintenance requirements," notes King.

Long-time reliability

"During the planning stages of this new fiber network, our main concern was its stability and endurance," says nwa`s Estep. "The extra precautions we took with our most critical links became standard procedures for the entire installation."

The longest cable run was to the training center, which is about 5400 feet from the main switching center. An armored cable was used for this run and some of it was buried, while the remainder was strung aerially. The cable consisted of 30 fibers, which were terminated to a 48-port fiber-distribution panel.

Before the new network backbone was installed, three of the five backbone cable segments were strung between poles. The new network called for installing several short runs underground, where they were pulled through conduits. Every cable installed was documented. Cable meter marks were recorded for each significant geographical detail along its route. Thus, if a break occurs, it can be located quickly relative to building corners, conduits, cable trays, or wooden poles, and the damage repaired.

The fiber itself was provided by Alcoa Fujikura Ltd. (Duncan, SC). The company was able to provide the fiber to nwa`s exact specification. Contractors were then responsible for installing it correctly, which determines long-term reliability. "nwa asked us to include testing of each fiber before it was installed. After termination, each fiber was tested in a dual range," states King. These tests included recording detailed high- and low-frequency performance charts. The data was supplied for each fiber by an optical time-domain reflectometer, which measures fiber signal attenuation, helps evaluate splice and connector joints, and simplifies fault location.

The test data was provided as machine-readable data files. As a result, there is a benchmark of each fiber`s characteristics that can be used to track any performance changes.

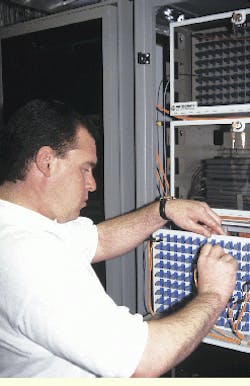

Dan Ellis, site supervisor for installation company Interwest Telecom Services (Richland, WA), installs fiber-optic connectors on a patch panel.

The layout for Northwest Alloys` fiber network contains 24/6 multimode/ singlemode fiber cables and 48/12 multimode/singlemode cables.

Northwest Alloys (Addy, WA) produces magnesium ingots and ships them to other manufacturers to create products such as aluminum alloys.

Carol Everett (Holliston, MA) is a freelance technical writer for Ortronics Inc. (Pawcatuck, CT).

Carol Everett (Holliston, MA) is a freelance technical writer for Ortronics Inc. (Pawcatuck, CT).