Intrabuilding riser cable-- a look at the basics

Riser or backbone cable is at the heart of most intrabuilding cabling jobs. Installing it properly is vital to assuring that the telecommunications infrastructure performs to specification.

Michael Collado and Peter Heller

ExtraNet Inc.

Just as water pipes and power lines run hidden beneath building floors and behind walls, riser cable performs its vital functions out of sight of the people it serves. And like its invisible cousins, riser cable`s "out of sight, out of mind" status moves rapidly to the forefront of awareness when service is disrupted. That is why cabling installers must be familiar with the standards governing riser systems--so their finished job conforms to these standards.

Delivering a quality installation calls for much more expertise and care today than it did only a few years ago. Why? As access to, or exchange of, information permeates all aspects of society, the role of riser cable becomes crucial to your customers-- building owners and managers as well as management information system (MIS) and information technology (IT) personnel working in those buildings.

Be prepared to work with personnel responsible for the organization`s network who have a basic understanding of riser cable and can speak the language when negotiating with cable manufacturers and system installers. You will find more and more customers equipped to evaluate your work. Customers who have invested substantial sums in network upgrades are not going to accept shoddy installation techniques that can lead to early or frequent failures.

Installers can help avoid problems by taking advantage of training courses offered by professional organizations such as bicsi (Tampa, FL), which is now conducting programs leading to registration as an apprentice, installer, or technician.

What is riser cable?

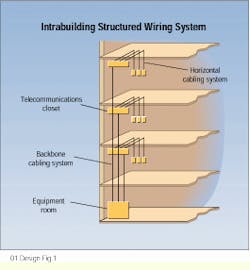

Riser cable, first named thus because it "rises" between the floors of a multistory building, is also called backbone cable. It is the primary conduit of a premises distribution system carrying voice, data, and video from the point where those communications enter a building--the outside plant interface or service entrance facility.

The cable itself is but one part of the building`s backbone system, however. Other components, in addition to the service entrance facility, include cable pathways, telecommunications closets, equipment rooms and related hardware, and support facilities.

Riser cable can be used for data communications (including video), video alone (as in community access or closed circuit television), or voice communications. Since cable requirements differ for each service, planning can become difficult. This is because future uses of the backbone wiring can range from the predictable to the entirely unknown. Facility managers of owner-occupied buildings feel hard-pressed to predict what their requirements may be only a few years ahead. This fact makes it advisable to suggest separate riser systems for different applications (such as voice and data) that follow parallel routes through pathways, closets, and equipment rooms.

Considering the predominance and importance of data-- including Internet access and interactive computing--we will focus here on optical-fiber backbones. Discussion will center on what is termed a physical star wiring topology. This wiring pattern accommodates logical bus, ring, and tree topologies.

However, other than presenting a general overview, we will not address the type or amount of cable to install. Those topics are within the domain of MIS and IT personnel, their consultants, and cable manufacturers, who will work together to size the installation to satisfy current and expected requirements.

Choosing the medium

If they can do so while remaining within budget, system designers will attempt to be all things to all users. They will make the trade-offs necessary to deliver the widest range of services through their backbone system. Other factors affecting their design include providing a flexible medium with respect to supported services, knowing the required useful life of backbone wiring, and taking into account the site size and user population.

Fortunately, standards are available to guide the cable specification process. Those relating to optical-fiber (as well as copper) cable backbone systems are contained in the ansi/tia/eia-568a standard, issued jointly by the American National Standards Institute (ansi--New York, NY), the Telecommunications Industry Association (TIA--Arlington, VA) and the Electronic Industries Association (EIA--Arlington, VA).

In addition to copper shielded and unshielded twisted-pair (UTP) cable and coaxial and twinaxial cabling systems, these specifications cover

- 62.5/125-micron multimode optical fiber,

- 50/125- or 100/140-micron multimode optical fiber,

- singlemode optical fiber.

In the case of multimode fiber, the numbers represent the core and cladding diameters.

Installation criteria

Physical locations that support a riser system include the telecommunications service entrance and the nearby equipment room that houses the main crossconnect. From the main crossconnect, risers can extend to telecommunications closets, which serve a designated area; intermediate crossconnects that serve multiple telecommunications closets; or horizontal cross- connects that serve a remote telecommunications closet or a single floor of an installation. The telecommunications closet is where backbone systems interface with horizontal wiring.

Note that no more than two levels of crossconnections--the main and one intermediate--should be employed in a star wiring topology. Moreover, connections between any two telecommunications closets should pass through no more than three crossconnects, not including the horizontal crossconnect.

Ideally, a riser cable system in a multiple-floor building will pass through vertically aligned closets using connecting sleeves or slots. This design provides every floor with access to the backbone sheath and permits circuits to be distributed to each floor. Vertically aligned closets also ease management of a riser system because identification of each cable`s function is simplified. Some economies may be realized, as well, by placing intermediate crossconnects on every "nth" floor, depending on system requirements.

Note that slots and sleeves must extend above the floor level by a minimum of one inch, be equipped with firestopping, and otherwise conform to the National Electrical Code, chapters 7 and 8, as well as local fire codes. While the ansi/eia/tia-569 standard contains general guidelines for sizing floor sleeves and slots, a rule of thumb is to design sleeves with a 4-inch diameter, unless the building`s structural engineer rules otherwise or obstructions are present. Smaller-diameter sleeves do not save money, and installing extra sleeves during initial construction will save labor costs later when system expansions are required.

Telecommunications closets should not be collocated with electrical closets, since any copper wire used for voice or data may be subject to electromagnetic interference from nearby electrical services.

Open cable shafts and enclosed metallic raceways or conduits are alternatives to sleeves or slots, but elevator shafts are not an option. When raceways or conduits are used, fill-requirement tables provide recommendations on the amount of cable that can be installed and the minimum radius of bends.

Specifications covering the permissible length of riser cable are geared to help ensure that the system can accommodate data transmission loads. They do not necessarily apply to telephony or low-speed data. Optical-fiber systems, because of low signal loss when properly installed, accommodate longer runs than copper systems.

For 62.5/125-micron optical-fiber cable, for example, the maximum recommended distance between main and intermediate crossconnects is 4920 feet. Also, it is recommended that intermediate and horizontal crossconnects be no further than 1640 feet apart. However, the distance between main and intermediate crossconnects can increase to up to 6560 feet (4920 feet plus 1640 feet) as the intermediate-horizontal crossconnect distances decrease from the maximum recommended value.

For singlemode fiber, the maximum distance between main and intermediate crossconnects is 8200 feet, while the maximum intermediate-horizontal distance is 1640 feet. If telecommunications equipment is connected directly to an intermediate or main crossconnect, connecting cables can be no longer than 98 feet.

Installation guidelines

Even before the job begins, anticipate that customers will check your credentials and reputation. Spotlight your familiarity with all aspects of the system, including handling and splicing optical-fiber systems. Be prepared to offer references, and if they are not asked for, volunteer to provide them.

Understand that building managers or end-user MIS and IT personnel do not have the time to monitor an installation full-time. But you should expect them to be visible to your crews frequently, looking for potential problems. Indeed, you should welcome these inspections, because a single walk-through inspection at the completion of a job is not the best way (or time) to spot work that may need corrective action.

Schedule meetings with the customer and the building`s structural engineer to obtain specific information about floor penetrations, the use of open shafts, and building structural members that may be employed to support the weight of the cable as well as other hardware associated with the project.

Although specifying the cable may not be your responsibility, you can show interest by asking if the riser cable capacity (in megabits per second) is properly sized for the application, and you can ensure that spare fiber pairs are allocated for expansion and redundancy.

Telephone companies are beginning to offer high-speed, 155-Mbit/sec Asynchronous Transfer Mode (ATM) service. To be able to take advantage of public ATM service now or in the future, it is probably a wise choice to install ATM-compatible cable at the outset.

A riser/backbone system is the heart of a telecommunications infrastructure. As rapid access to data and real-time exchange of information become more crucial to the success of enterprises, their reliance on riser systems will increase accordingly. As the installer of such systems, you should put your trust in accepted, proven, standards-compliant products. When budget permits, engage the services of a qualified consultant to assist in the overall planning and design process if you do not have the necessary expertise in-house.

Project Checklist

As work on your installation project proceeds, the following checklist may be helpful in ensuring that guidelines are followed and no vital steps have been omitted.

- Is the cable being protected from stress during installation? If the work area permits, optical-fiber cable should be lowered from the top floor using winches and rolling hitch knots in conjunction with other protective devices to minimize the stress of weight on the cable. Permanent cable supports should be in place before the cable is lowered.

- Do not tie riser cable to vertical steam or water piping, including sprinkler system piping. Riser cable should be snugged to support systems that are firmly toggle-bolted to walls. Be sure to follow the manufacturer`s recommendations in spacing support members.

- Telecommunications closets and electrical closets cannot share the same space.

- If the installation requires riser cable to pass over work areas and above ceilings used as heating, ventilating, or air conditioning air returns, it must be plenum-rated.

- Do not use bend radiuses greater than those permitted by the cable manufacturer.

- Permanently identify the cables so that there will be no confusion as to what each carries and where it goes.

- Make sure that conduits, raceways, and innerducts through which cable may be pulled are large enough to accommodate future additions to the network. Remember that installation costs represent a substantial portion of building the network and that ongoing additions, moves, and changes to the network are highly likely.

- Deliver passing test reports regularly during the construction of the riser cable system. Pay close attention to reports on the performance of optical-fiber splices.

- Deliver complete, accurate, and clear diagrams of the installation--preferably computer-aided design drawings--showing all routes and equipment related to the riser system. This database becomes an ongoing record of the system. It should extend to horizontal wiring and must be kept current by end-user personnel or the independent contractor responsible for adds, moves, and changes. Large systems, especially, should be equipped with computer support to quickly identify problems that develop over time.

- Insist on a complete inspection and certification by the cable manufacturer. This is essential if the manufacturer`s guarantee is to be honored, and it helps protect you as well.

Within a building, it is backbone cable that typically runs from the main crossconnect in the equipment or computer room to intermediate crossconnects in telecommunications closets on each floor. From the closets, horizontal cable runs link the intermediate crossconnects to workstation equipment. Because this backbone cable often rises vertically from floor to floor, it is also called riser cable.

Michael Collado is president and Peter Heller is manager of operations at New York City-based ExtraNet Inc., an integration firm specializing in infrastructure cabling, telephone systems, LAN networking, and the Internet.