Easy-on-the-hands punch-down efficiency

A trustworthy everyday tool sees new trends for improved ergonomics.

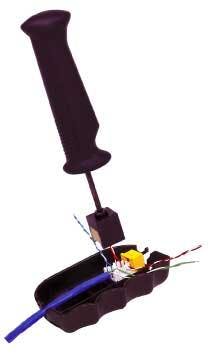

Punch-down tools get a lot of use on a jobsite since they are essential for terminating cable at the IDC blocks, patch panels, and workstation jacks. While these trustworthy tools have been around for decades, and the basic concept remains the same, vendors are constantly concerned with improving the labor and ergonomics involved in the process. Several new features and the growing trend toward vendor-specific tools reduce the amount of physical stress and time required.

Focusing efforts

The process of punching down the cable refers to the physical force required to penetrate or remove the wire insulation as the electrical connection is made. "Punch-down tools have evolved from screwdrivers, little wooden blocks, and round handles to designs that thoroughly improve ergonomics," says Les Shutts, engineering manager, Paladin Tools (www.paladin-tools.com). "Today's punch-down tools have integrated rubber, contour gripping, and impact mechanisms that decrease the user's hand exertion force."

For example, a tool that delivers 25 pounds of impact force with only 10 pounds of user compression force reduces hand exertion by 15 pounds.

Most recent modifications to punch-down tools stem from the introduction of Category 5e and 6 UTP cabling. "Tool manufacturers understood the transition from 24 gauge wire to 23 and 22 gauge that came with moving to Category 5e and 6," says Shutts. "This meant that the existing punch-down tools would require at least two punches to terminate." According to Shutts, perceptive tool manufacturers foresaw the changes and redesigned their impact mechanisms to deliver more force, ensuring that one single punch would do the job.

Before punching down, the outer cable jacket is stripped, individual pairs are split, and wires laced to the IDCs. "Lacing the conductors is the most time-consuming portion of the process," says Paul Alexander, product line manager, Harris Corporation (www.harris.com). "While connectivity manufacturers have eased the lacing of less-flexible Category 6 wire by spacing out contacts, no tool in the world is going to do the lacing for you. The focus has to be on improving the punch-down process."

In late 2003, Paladin improved the design of its SurePunch Pro to make it more efficient and comfortable to use. New features include a shorter handle and a spring mechanism requiring less force, and a detachable light for working in dark cabinets or buildings without power. "One of the biggest complaints we had was that our customers were sick and tired of working in the dark," says Shutts. "Installers told us that headlamps get in the way in tight cabinets and vest lamps get snagged. They needed something else to light up the area."

The SurePunch Pro also features blade storage, integrated cabling preparation tools, and adjustable impact for various types of cable.

Influential changes

Universal multi-wire punch-down tools have been available for standard 66 and 110 connecting blocks with in-line IDCs, and single wire punch-down tools have been de facto for terminating workstation jacks. But the evolution to Category 6 has sparked a growing trend in vendor-specific multi-wire tools for IDC blocks, patch panels, and jacks.

"In the past, 110 blocks were the same footprint, and the tools were pretty much universal," says Brian Davis, product manager for copper connectivity, Tyco Electronics (www.tycoelectronics.com). "With Category 6, vendors developed proprietary designs to reduce crosstalk, and punching down in general became a more difficult process due to the tightly twisted pairs and stiffer Category 6 cable." According to Davis, it takes anywhere from 30% to 50% percent more time to terminate Category 6 cable than Category 5.

"Many say we need standardization, but everything is moving away from standardization to sell systems as a whole," says Shutts. "Manufacturers had to spend the money to redesign products to meet Category 6 performance criteria. So, rather than coming up with a standard, they've created their own designs." According to Shutts, however, proprietary designs affect the tool industry because there's a higher cost associated with crafting punch-down tools to work with various manufacturers' jacks.

One-hit wonders

In November 2002, Hubbell Premise Wiring (www.hubbell-premise.com) introduced the first multi-wire punch-down tool for jacks. The Hubbell 1-Punch is designed to simultaneously punch down and cut all 8 wires laced to Hubbell's Xcelerator Category 5e and 6 jacks. "A lot of R&D went into designing a tool that saved time and provided a consistent reliable termination," says Glenn Kierstead, copper systems product manager for Hubbell. According to Kierstead, the 1-Punch is keyed, fitting only one way on the jack to eliminate user error.

Hubbell also offers a 4-pair punch-down tool for use with its Nextspeed Category 6 110 crossconnect system. According to Kierstead, Hubbell will introduce a punch-down tool with interchangeable heads for punching down all four pairs on Hubbell jacks, patch panels, and cross-connect systems.

In January, Tyco Electronics introduced the AMP Netconnect SL Series Jack Termination Tool for use with its Category 3, 5e, and 6 SL Series jacks. The tool also terminates and cuts all eight wires at once but Davis notes that it also incorporates a lacing fixture, which reduces the chance for improper lacing that can decrease crosstalk performance. "It's much easier to lace the fixture," he explains. "The cable comes up through the middle, and because holding teeth achieve the pair split and hold the wire firmly in place, there is no need to untwist pairs all the way."

Both the lacing fixture and jack are inserted into the hand tool. Squeezing the handle pushes the jack into the lacing fixture and inserts and cuts the wires. According to Davis, the process is a controlled action that can reduce hand fatigue because it puts less force onto the jack than a typical punch-down tool. "When people comment on how different it is, I tell them that running water was different too, but I'm sure glad we have it," says Davis.

Next month, Harris Corp. (www.harris.com) will introduce the Jack Rapid 8-Wire Punch-down Tool for use with Leviton Category 5e jacks. "From our perspective, the connectivity vendors that have introduced multi-wire punch-down tools have helped create awareness," says Joan Hartzell, marketing communications manager for Harris. "Most contractors install products from several different vendors, and our goal is to offer one tool for many types of jacks. We are more geared to designing and developing multi-wire punch-down tools."

The Jack Rapid features a head that holds the jack and a handle featuring a trigger-type mechanism. "With the Jack Rapid, only one hand is needed to terminate, and the user doesn't need to be directly over the jack like with a typical punch-down tool," explains Alexander. "That makes our tool extremely wall friendly—it requires just one inch of slack to terminate the jack."

According to Alexander, the Jack Rapid provides a consistent termination every time, considerably reducing user error. Other than Leviton's Category 6 jacks, Harris can't yet say which jacks they will accommodate in the future. According to Alexander, market research pointed to the Leviton Category 5e jacks as one of the top three in the residential and commercial marketplace: "We want to make this tool available to accommodate the most popular jacks used in the field. Installers will be able to purchase various Jack Rapid replacement heads for specific jacks, instead of having to purchase completely separate tools for each vendor solution."

To be continued

As more connectivity manufacturers jump on board with vendor-specific multi-wire punch-down tools, how will this affect vendor choice on the jobsite? "If I'm looking at products that offer basically the same performance, and I see an accessory that allows me to complete terminations in less time and have a more reliable connection, that's the vendor I'm going to choose," says Davis.

Paladin Tools' Shutts agrees that from an installer standpoint, multi-wire punch-down tools have a labor cost savings, but unfortunately, many installers are not specifying the system. "Engineers are set on performance, and tools are typically an afterthought," says Shutts. "Those that are labor-savvy will count minutes and start paying attention to the tools for time savings, but most system engineers don't get down to that level."

Most industry professionals agree, however, that traditional single-blade punch-down tools will not be a thing of the past. "There will always be a demand," says Harris' Alexander. "Our multi-wire tool doesn't compete with our single-blade tools—it complements them."

While Shutts agrees that single-blade punch-down tools will be around for a long time, and the growing trend toward vendor-specific tools will continue, he envisions the possibility of punch-down tools eventually fading out altogether: "As long as the traditional systems are in use, punch-down tools will be around. If tool-less systems and mass termination systems take over, the whole idea of punch termination systems may go away completely. We'll keep finding faster and easier ways to do this."

Betsy Ziobron is a freelance writer covering the cabling industry, and a regular contributor to Cabling Installation & Maintenance. She can be reached at: [email protected]

Where to find punch-down tools...

ALLTEL COMMUNICATIONS PRODUCTS

Alpharetta, GA

www.alltelcpi.com

AMPNETCONNECT/TYCO ELECTRONICS

Harrisburg, PA

www.ampnetconnect.com

HARMAN ASSOCIATES

Brookline, MA

www.harmanassociates.com

HARRIS CORP.

Melbourne, FL

www.harris.com

HELLERMANNTYTON

Milwaukee, WI

www.hellermann.tyton.com

HUBBELL PREMISE WIRING

Stonington, CT

www.hubbell-premise.com

IDEAL INDUSTRIES

Sycamore, IL

www.idealindustries.com

LEMCO TOOL CORP.

Logan Station, PA

www.lemco-tool.com

NORDX/CDT

Pointe Claire, Quebec

www.nordx.com

PALADIN TOOLS

Oilville, VA

www.paladin-tools.com

PANDUIT CORP.

Tinley Park, IL

www.panduit.com

SUTTLE

Hector, MN

www.suttle-online.com

TEMPO/TEXTRON

Rockwell, IL

www.tempo.textron.com