Wiring a Category 5 110 modular patch panel

Robert Y. Faber, Jr.,

RCDD, The Siemon Co.

Problem

When terminating four-pair cables to the back of a 110-style modular patch panel, it is important to minimize the removal of the outer cable jacket. This is because the individual cable pairs tend to loosen up when they are no longer restrained by the jacket. This loosening may adversely affect the near-end crosstalk loss performance of the Category 5 cable at the point of termination. Although maintaining the jacketed portion of the cable as close to the point of termination as possible minimizes the risk that one or more cable pairs will loosen up, it also makes it more difficult to wire the back of the patch panel because of the numerous bulky jacketed cables in close proximity.

Solution

This procedure for terminating four-pair Category 5 unshielded twisted-pair cable onto a 110-style patch panel helps ensure that the length of pair untwist will not exceed the half-inch (13-millimeter) requirement for Category 5 in the American National Standards Institute/Telecommunications Industry Association/Electronic Industries Association standard 568A. It applies to patch panels with removable jack modules that allow the installer to terminate cables from the front of the panel.

Procedure

1) Mount the patch panel on an equipment rack or equivalent wall-mount hardware.

2) Mount a rear wire manager behind the patch panel--preferably near its top. If mounted too low, it may obstruct access and make cable termination from the rear of the panel difficult.

3) Route cables from the back of the patch panel through its coupler opening and loosely attach them with cable ties to the wire manager. Remember to leave enough cable slack so that a coupler may be removed from the panel for retermination, if necessary.

4) Remove only as much cable jacket as is necessary to terminate the conductors.

5) Lace the conductors into the retention slots on the 110 connecting block. Be careful not to untwist the cable pairs more than one-half inch for Category 5 cables (and no more than 1 inch for Category 4 cables). Inspect the cable pairs before you terminate the wires.

6) Terminate the conductors using an automatic impact tool or equivalent. This action will seat the conductors one at a time and cut off the excess wire at the same time. Snap the coupler into the patch panel.

7) Once all of the cables have been terminated and the couplers have been snapped into the panel, dress the cable slack behind the panel and tighten the cable ties.

For each coupler, labeling may be done on the patch-panel faceplate`s paper tabs. Clear plastic covers can then be applied.

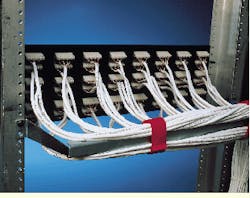

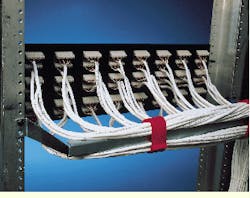

Viewed from the rear, a Category 5 110-style modular patch panel shows a minimum of cable jacket removed for termination. Careful wire management keeps terminated cables from being pulled loose.

Robert Y. Faber, Jr., RCDD, is director of educational services at The Siemon Co., Watertown, CT.